Welcome To Hebei Xiongan Hengyun Technology Co., Ltd.

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

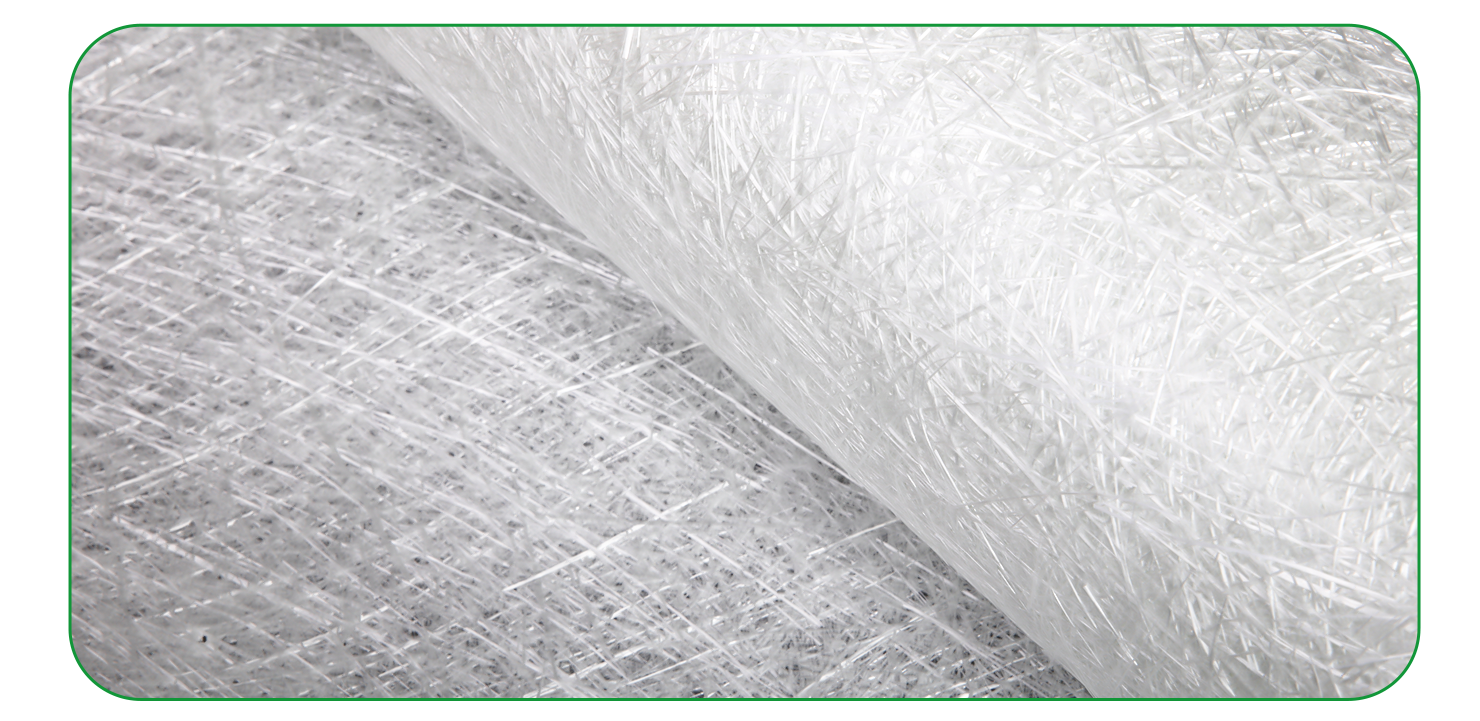

Fiberglass Chopped Strand Mat: The Versatile Foundation of Composite Manufacturing

2025-06-18

Fiberglass Chopped Strand Mat: The Versatile Foundation of Composite Manufacturing

I. Introduction

Fiberglass Chopped Strand Mat (CSM) is one of the most ubiquitous and fundamental reinforcement materials used in the composites industry. Its simplicity, cost-effectiveness, versatility, and ability to conform to complex shapes make it a cornerstone material for countless applications, ranging from boat hulls and bathtubs to automotive components and corrosion-resistant tanks. Consisting of randomly oriented chopped glass fibers held together by a soluble binder, CSM provides isotropic reinforcement and excellent resin compatibility, facilitating easy wet-out and laminate build-up.

II. Composition and Manufacturing

-

Glass Fibers: The core component is glass fiber, typically made from E-glass (electrical grade), chosen for its good strength, electrical insulation properties, and cost-effectiveness. Occasionally, specialized glasses like C-glass (chemical resistance) or E-CR-glass (corrosion resistant) are used for specific applications.

-

Chopping: Continuous glass fiber strands, formed by drawing molten glass through bushings and applying a sizing (a chemical coating crucial for fiber protection, handling, and resin bonding), are chopped into short lengths. Common chop lengths range from 25mm (1 inch) to 50mm (2 inches). This length is a critical balance: long enough to provide reinforcement and entanglement, short enough to allow the mat to conform easily to curves.

-

Mat Formation: The chopped strands are randomly distributed (like a felt) onto a moving conveyor belt. This random orientation is key to CSM's isotropic properties – strength is relatively uniform in all directions within the plane of the mat.

-

Binder Application: A powdered or emulsion-based chemical binder is applied uniformly over the distributed strands. Common binders include

-

Curing/Oven: The binder-laden mat passes through an oven. Heat cures (sets) the binder, bonding the chopped strands together at their intersecting points to form a coherent, handleable sheet. The binder must be strong enough to hold the mat together during handling and processing, yet dissolve readily in the resin matrix (polyester, vinyl ester, epoxy) during laminate fabrication.

-

Rolling and Packaging: The cured mat is cooled, trimmed to width, rolled onto cores, and packaged for shipment. Standard widths are typically 1m or 1.25m (approx. 39" or 49"), and rolls vary in length depending on weight.

III. Key Characteristics and Properties

-

Random Fiber Orientation: The defining feature. Provides isotropic reinforcement – mechanical properties (tensile, flexural strength) are similar in all directions within the plane of the laminate. This contrasts sharply with woven fabrics, which have directional strength.

-

Excellent Conformability: Due to the short, randomly oriented fibers and the "blanket-like" structure, CSM drapes exceptionally well over complex curves, compound shapes, and intricate molds without wrinkling or bridging. This is its major advantage over woven rovings or fabrics.

-

High Resin Absorption/Wet-Out: The random structure creates a relatively open network with high loft (bulk). This allows resin to penetrate quickly and easily throughout the mat, leading to fast and thorough wetting-out. This is crucial for manual laminating processes (hand lay-up, spray-up).

-

Laminate Build-Up: CSM provides significant thickness per layer (high bulk) compared to woven fabrics of similar weight. This makes it highly efficient for quickly building laminate thickness, providing core structure, and creating a smooth surface finish over a mold.

-

Good Interlaminar Shear Strength: The random fiber entanglement helps create a good mechanical key between layers in a laminate, contributing to interlaminar strength.

IV. Mechanical Properties

-

Tensile Strength: Moderate (lower than unidirectional or woven fabrics).

-

Tensile Modulus: Moderate.

-

Flexural Strength: Moderate.

-

Impact Strength: Good, due to the random fiber network's ability to absorb and distribute impact energy.

-

Isotropy: High (properties similar in X, Y, and diagonal directions).

V. Common Weights

CSM is specified by its weight per unit area, typically grams per square meter (gsm) or ounces per square foot (oz/ft²). Common weights include:

-

225 gsm - Very light, for surfacing veils or thin laminates.

-

300 gsm - Standard lightweight, common for surface layers.

-

450 gsm - The most common and versatile weight.

-

600 gsm - For quicker build-up, slightly stiffer handling.

VI. Applications

CSM's versatility translates into an incredibly wide range of applications across numerous industries:

-

Marine: Boat hulls, decks, stringers, bulkheads, small craft, canoes, kayaks (often combined with woven roving or fabrics).

-

Transportation: Truck cabs and panels, bus components, recreational vehicle (RV) panels, trailer parts, interior components.

-

Construction & Infrastructure: Bathtubs, shower stalls, shower trays, vanity tops, swimming pools, hot tubs, septic tanks, water tanks, roofing panels, ductwork, architectural features.

-

Corrosion-Resistant Equipment: Chemical storage tanks, fume hoods, scrubbers, ducting, grating, covers (often using vinyl ester resin).

-

Industrial: Machine guards, covers, enclosures, electrical components (switchgear covers), tool handles.

Conformability,Fiberglass Chopped Strand Mat,Resin Wet-Out,Cost-Effectiveness

Related news

Fiberglass Chopped Strand Mat: The Versatile Foundation of Composite Manufacturing

2025-06-18

Fiberglass Fine Yarn: The Invisible Strength Behind Modern Materials

2025-06-17