Welcome To Hebei Xiongan Hengyun Technology Co., Ltd.

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

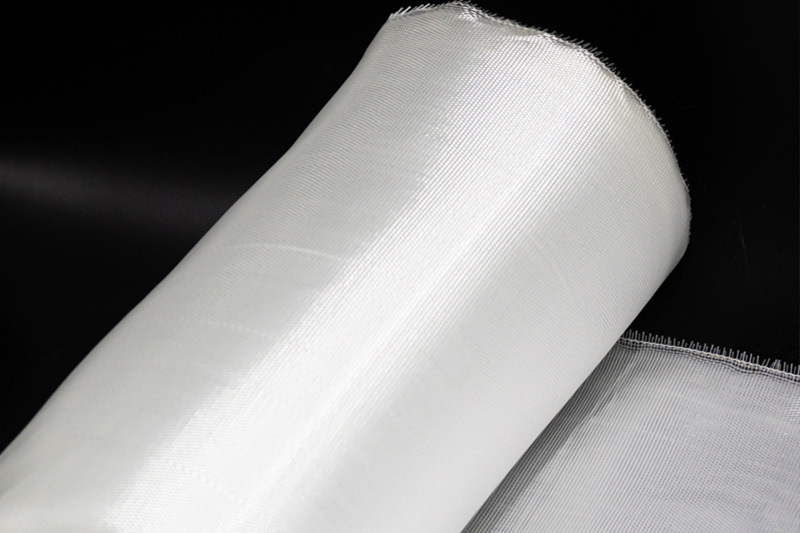

Fiberglass Fine Yarn: The Invisible Strength Behind Modern Materials

2025-06-17

Market Overview

The global fiberglass yarn sector is weaving its way to a projected $3.1 billion valuation by 2028, with demand growing at 7.2% annually. What makes this market particularly compelling is the shift toward high-value specialty yarns, which now command 40% premium pricing over standard grades.

Technical Breakthroughs

1. The Thin Revolution

-

Sub-10 Micron Marvels: New spinning technologies produce yarns finer than human hair (5-9μm), enabling:

✓ Unprecedented fabric drape for automotive interiors

✓ Smoother surface finishes in premium composites

✓ Tighter weaves for aerospace-grade reinforcements

2. Smarter Coatings

-

Intelligent Sizing Systems: Next-gen coatings now provide:

✓ Self-lubricating properties for faster weaving (18% productivity boost)

✓ UV-resistant formulations for outdoor applications

✓ Conductive layers for smart textiles

3. Hybrid Innovations

-

Glass-Carbon Fusion: Combining fibers to create yarns with:

✓ 30% higher stiffness than pure glass

✓ 50% the weight of traditional reinforcements

✓ Better impact resistance for sporting goods

Application Spotlight

Electronics Reinvented

-

5G Infrastructure: Ultra-low dielectric yarns for antenna substrates

-

Flexible Circuits: Woven fiberglass enabling bendable electronics

Automotive Evolution

-

EV Battery Systems: Fire-resistant separators with ceramic-enhanced yarns

-

Next-Gen Interiors: Ultrathin (yet durable) seat fabrics reducing weight

Industrial Game-Changers

-

Smart Pipelines: Yarns with embedded sensors for leak detection

-

Space-Grade Composites: Radiation-resistant weaves for satellite components

Global Production Landscape

Asia's Dominance

-

China's mega-factories now produce 62% of global supply

-

Vietnam emerging as low-cost alternative with 15 new plants in development

Western Renaissance

-

U.S. and EU investing in:

✓ Robotic spinning systems (25% less energy)

✓ Closed-loop recycling (up to 40% recycled content)

✓ Military-spec yarns with enhanced ballistic properties

Sustainability at the Core

The industry's green transformation includes:

-

Bio-Based Sizing: Plant-derived coatings replacing petrochemicals

-

Low-CO₂ Formulations: New E-glass recipes cutting emissions by 35%

-

Circular Economy Models: Take-back programs for manufacturing scrap

The Future Thread

As smart factories and AI-driven quality control reshape production, fiberglass yarn is evolving from a commodity to a high-tech engineered material - one that will continue to enable breakthroughs across industries while reducing environmental impact.

fiberglass yarn,composite materials,glass fiber market,sustainable manufacturing,conductive coatings

Related news

Fiberglass Fine Yarn: The Invisible Strength Behind Modern Materials

2025-06-17