Welcome To Hebei Xiongan Hengyun Technology Co., Ltd.

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Revolutionizing Reinforcements: Advanced Fiberglass Cloth Unveiled

2025-06-16

Revolutionizing Reinforcements: Advanced Fiberglass Cloth Unveiled

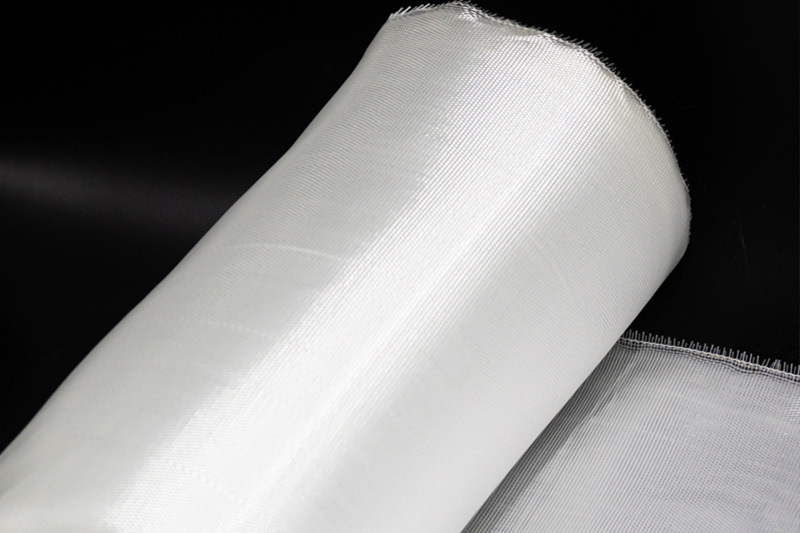

Fiberglass cloth, a fundamental engineered textile, is the cornerstone of countless composite materials that shape our modern world. It's not merely fabric; it's a precisely engineered reinforcement, transforming resins into structures of exceptional strength, lightness, and versatility.

I. Fundamental Definition and Composition

At its core, fiberglass cloth is a textile material woven from continuous filaments of glass fiber. These filaments start as raw materials like silica sand, limestone, soda ash, and other minerals, melted in furnaces at extremely high temperatures (typically exceeding 1400°C / 2550°F). The molten glass is then extruded through microscopic bushings (spinnerets) to form individual filaments, each only microns in diameter (typically 5-24 microns). Hundreds of these filaments are gathered together immediately after formation into a single strand called a "roving" or "yarn." It is these rovings or yarns that are then woven together on specialized looms, much like traditional textiles (cotton, linen), but designed to handle the abrasive nature and high tension of glass fibers.

II. The Manufacturing Process: From Melt to Mesh

Batching: Raw materials are precisely weighed and mixed according to the specific glass formulation required (e.g., E-glass, S-glass).

Melting: The batch is fed into a high-temperature furnace, melting into a homogeneous, viscous liquid.

Fiberization: The molten glass flows into heated bushings (platinum alloy plates with hundreds or thousands of tiny holes). As the glass extrudes through these holes, it forms continuous filaments. A high-speed winder below the bushing pulls the filaments, attenuating them to the desired diameter.

Sizing Application: Immediately after formation, a critical chemical coating called "sizing" or "coupling agent" is applied to the filaments. This serves multiple vital functions: lubricating the filaments to prevent abrasion during subsequent processing, binding filaments together into a strand (roving), protecting the glass from environmental moisture, and crucially, promoting adhesion between the inert glass surface and the resin matrix later used in composites. Different sizings are formulated for compatibility with specific resins (polyester, epoxy, vinyl ester).

Roving Formation: Hundreds or thousands of individual filaments, now coated with sizing, are gathered together into a single, continuous strand known as a roving. These rovings are wound onto forming packages (bobbins).

Weaving: Rovings (or sometimes finer yarns made by twisting multiple rovings) are loaded onto a loom. Traditional weaving techniques (plain, twill, satin weaves – see below) interlace the warp (lengthwise) and weft (crosswise) yarns to create the cloth. Looms for fiberglass are robust to handle the abrasive fibers and maintain precise tension control. After weaving, the cloth edges (selvedges) are often treated to prevent unraveling.

Finishing: The woven cloth may undergo additional treatments like heat cleaning (to remove residual sizing for specific applications requiring maximum resin adhesion) or application of specialty finishes. Finally, it's inspected for defects, rolled onto cores, packaged, and shipped.

III. Key Properties: Why Fiberglass Cloth Excels

High Tensile Strength: Glass fibers possess exceptionally high tensile strength (resistance to pulling forces) relative to their weight, significantly higher than steel wire of the same diameter. This strength is locked into the composite structure by the cloth.

Lightweight: Glass fibers are inherently low density. The resulting cloth and composite offer a superior strength-to-weight ratio, crucial for applications like aerospace and transportation where weight savings are paramount.

Dimensional Stability: Fiberglass cloth exhibits minimal stretch or shrinkage under load and across wide temperature ranges, ensuring the composite maintains its shape and dimensional accuracy.

Chemical Resistance: Especially E-glass cloth offers excellent resistance to a wide range of chemicals, solvents, and alkalis, making composites suitable for corrosive environments (chemical tanks, pipes, marine applications). Resistance to acids depends on the glass type and resin used.

IV. Types of Weaves: Structure Dictates Performance

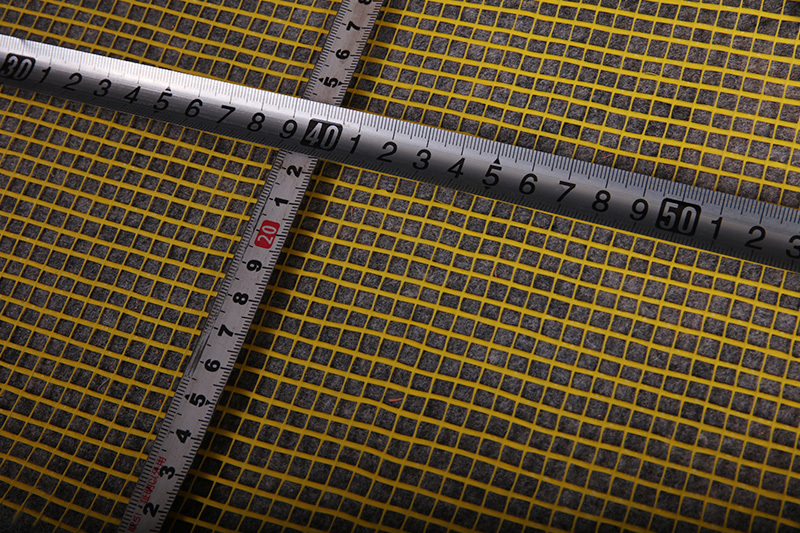

Plain Weave: The simplest and most common. Each warp yarn passes alternately over and under each weft yarn (1/1 pattern). Creates a stable, balanced fabric with good interlaminar shear strength. Relatively porous. Can have a "checkerboard" appearance. Less drapeable than other weaves. Common for general-purpose reinforcement.

Twill Weave: Warp yarns pass over multiple weft yarns before going under one or more (e.g., 2/2, 4/4). Creates a diagonal rib pattern on the surface. Offers better drape and conformability to complex curves than plain weave. Slightly higher strength-to-weight ratio due to longer, less crimped yarns. Good impact resistance. Common for boat hulls, automotive panels.

Satin Weave: Features long "floats" where warp yarns pass over multiple weft yarns before interlacing (e.g., 4/1 harness satin, 8/1 harness satin). Minimizes yarn crimp, maximizing tensile strength and stiffness in the primary direction. Excellent drape and conformability. Produces the smoothest composite surface finish. Less stable than plain or twill, can be more difficult to handle. Used in aerospace, high-performance sporting goods, surfaces requiring excellent finish.

V. Glass Types: Tailoring the Fiber

E-Glass (Electrical Glass): The workhorse, accounting for over 90% of all fiberglass reinforcement. Offers excellent strength, electrical insulation, moisture resistance, and good chemical resistance (especially alkalis) at a low cost. Standard for most general-purpose composite applications (boats, tanks, automotive parts, wind blades).

C-Glass (Chemical Glass): Enhanced resistance to acid corrosion compared to E-glass. Used in chemical storage tanks, acid filtration systems, and battery boxes.

VI. Applications: Where Fiberglass Cloth Reigns

Marine Industry:

The quintessential application. Hulls, decks, bulkheads, masts, and other structural components of boats (from kayaks to yachts) rely heavily on fiberglass cloth (often woven roving combined with mat) and polyester resin for strength, lightness, water resistance, and corrosion resistance.

Transportation:

Automotive: Body panels, bumpers, hoods, spoilers, interior components, leaf springs (especially trucks), underbody shields. Reduces weight, improves fuel efficiency, and offers design freedom.

Aerospace: Interior panels, ducting, radomes, fairings, secondary structural components (S-glass/epoxy). Critical for weight savings.

Rail & Mass Transit: Interior panels, seats, luggage racks, exterior cladding.

Construction & Infrastructure:

Pipes & Tanks: Chemical storage tanks, underground fuel tanks, sewage pipes, water pipes (corrosion resistance).

Building Panels: Roofing, wall panels (often sandwich panels), translucent skylights.

GFRC: Architectural cladding, decorative elements, countertops.

Rehabilitation: Seismic strengthening of concrete columns and beams using FRP wraps.

Composite Reinforcement,glass fiber cloth,High Strength,Chemical Resistance

Related news

The Indispensable Material: Fiberglass Mesh Cloth

2025-06-10