Welcome To Hebei Xiongan Hengyun Technology Co., Ltd.

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

The Unsung Hero of Construction: Fiberglass Corner Mesh Strengthens Modern Builds

2025-08-27

Addressing a Classic Builder Challenge

In construction, minute details often separate a lasting, flawless structure from one plagued with issues. Building corners—both internal and external—have always been vulnerable, susceptible to cracks from settling, impact, or thermal changes. A simple but highly effective solution has gained prominence: Fiberglass Corner Mesh. This versatile product is strengthening projects globally, from residential renovations to major architectural landmarks, by delivering resilience, adaptability, and ease of use.

What Is Fiberglass Corner Mesh?

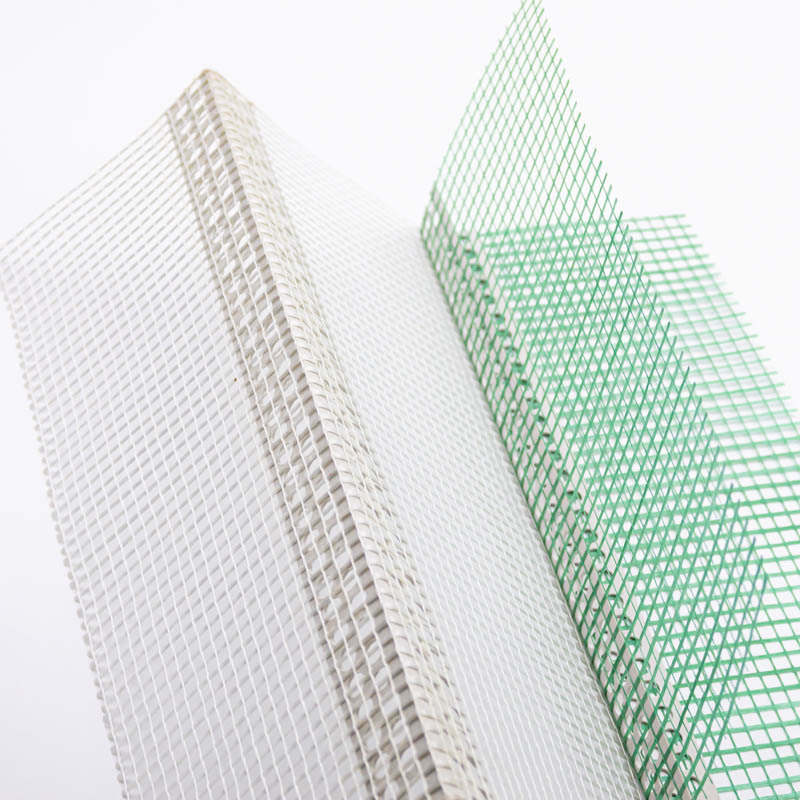

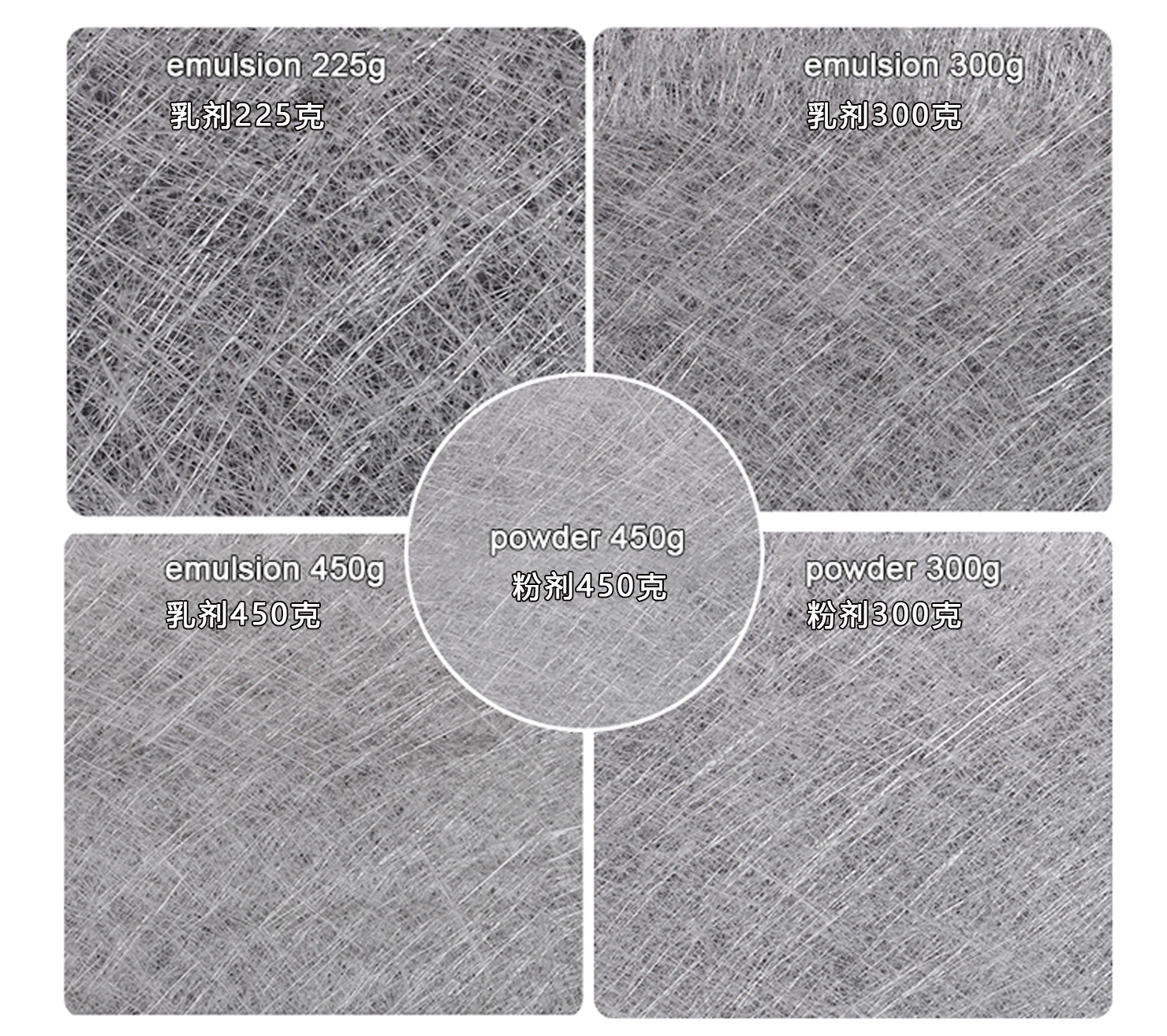

Fiberglass corner mesh is a specialized material used to reinforce wall corners. It consists of a woven fiberglass mesh pre-formed into a right angle, treated with an alkaline-resistant coating to endure cement-based plasters and mortars. A rigid paper or plastic spine along the center ensures a crisp edge and simplifies handling.

Applied by embedding into a mortar or adhesive base, the mesh integrates fully into the wall system. It acts as an internal skeleton, distributing mechanical and thermal stress to prevent cracking. Unlike metal beads, it combines high tensile strength with flexibility, accommodating natural building movement without compromising performance.

Why Fiberglass Is Replacing Traditional Materials

The transition from metal or plain paper to fiberglass corner mesh is fueled by distinct practical benefits:

Excellent Crack Resistance: The flexible, woven structure absorbs movement, reducing stress concentration. This minimizes hairline cracking over time, outperforming rigid alternatives like metal beads that can telegraph cracks or create pressure points.

Total Corrosion Resistance: Unlike metal, fiberglass doesn’t rust. Alkaline-resistant treatment prevents deterioration in cementitious materials, making it ideal exterior applications or moisture-prone interiors.

Lightweight and Easy to Apply: Easy to cut, bend, and install, it reduces labor time and physical strain. It conforms effortlessly to curves or uneven substrates, increasing versatility across projects.

Broad Compatibility: Suitable for drywall, EIFS, traditional stucco, tile work, and concrete repair, it offers a unified solution for diverse finishing needs.

Real-World Impact: Job Site to Final Inspection

These technical traits deliver measurable benefits:

Contractors save time with quicker installation and fewer callbacks thanks to long-lasting results. The reduced risk of post-construction cracks protects reputations and margins.

Architects and designers gain confidence specifying a solution that maintains aesthetic integrity and supports curved or custom details.

Property owners enjoy durable, low-maintenance corners that resist damage from impact or settling, preserving property value and appearance.

Looking Ahead: Innovation and Sustainability

Ongoing advances focus on increasing tensile strength and application features. From an environmental view, fiberglass mesh supports sustainable building through durability—extending service life and improving energy efficiency by sealing building envelopes. Its light weight also helps lower transportation emissions.

A Cornerstone of Quality Construction

Fiberglass corner mesh has evolved from a niche accessory to a necessary component, solving a perennial construction challenge with efficiency and reliability. It strengthens structures, simplifies builds, and ensures lasting quality, making it an indispensable part of modern finishing practice. In the quest to build better, it’s a small detail that makes a major difference.

Fiberglass corner mesh,Crack resistance,Alkaline-resistant,Construction reinforcement,Drywall corner bead,EIFS reinforcement,Stucco mesh,Corner protection,Building material sustainability,Construction efficiency

Related news

The Unsung Hero of Construction: Fiberglass Corner Mesh Strengthens Modern Builds

2025-08-27

2025-08-25

2025-08-22