Welcome To Hebei Xiongan Hengyun Technology Co., Ltd.

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Innovation in Reinforcement: How Next-Gen Fiberglass Chopped Strand Mat is Strengthening Global Industries

2025-08-25

The composites industry is witnessing a significant evolution in one of its most fundamental materials: Fiberglass Chopped Strand Mat (CSM). Long valued for its versatility and cost-efficiency, CSM is now at the forefront of a materials revolution, driven by breakthroughs in fiber technology, resin compatibility, and eco-conscious manufacturing. This isn't just an upgrade; it's a transformation that is enhancing product durability, streamlining production processes, and contributing to a more sustainable industrial future. From renewable energy infrastructure to next-generation transportation, the new era of CSM is reinforcing progress worldwide.

A Pillar of Modern Fabrication: The Core Strengths of CSM

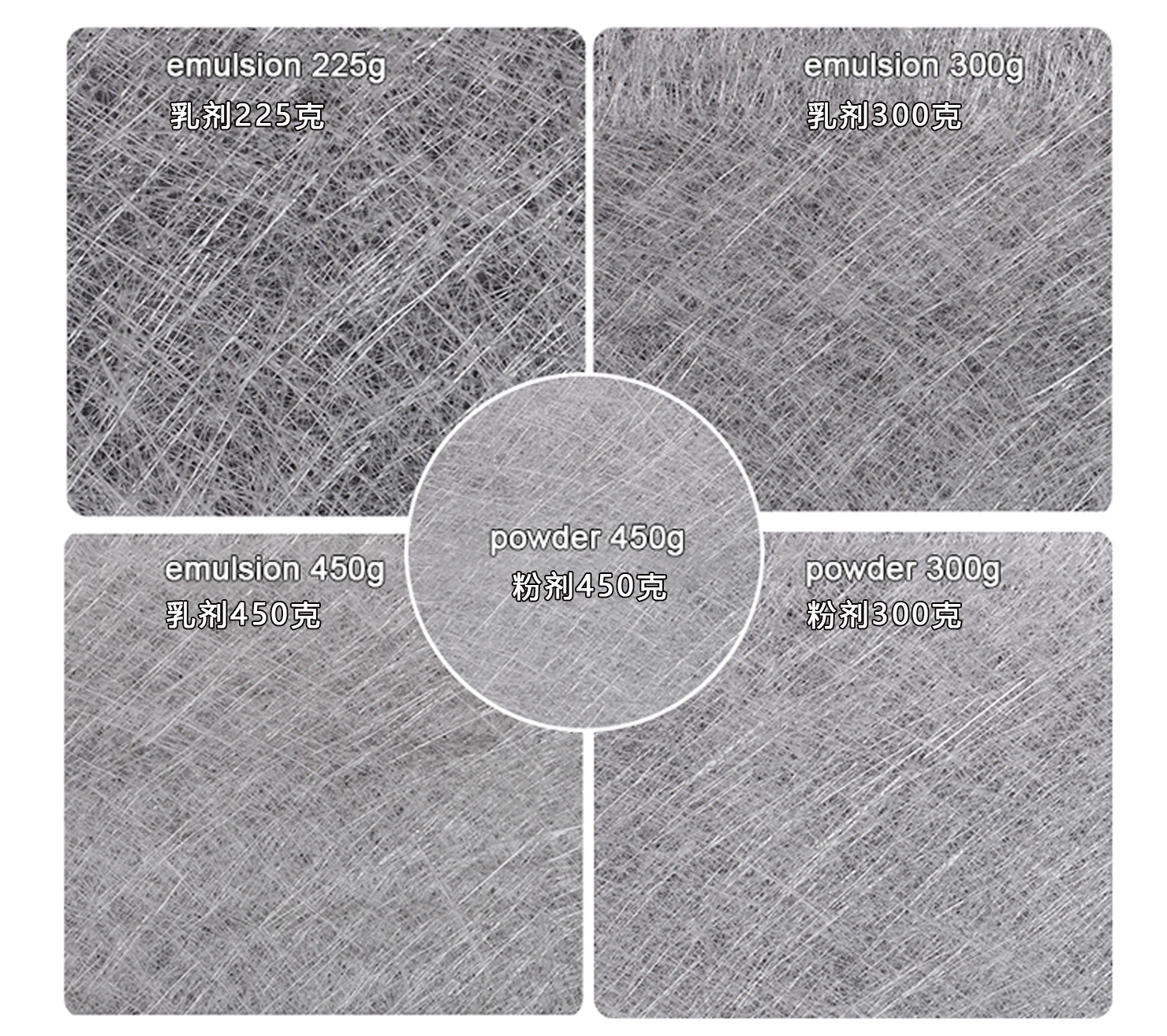

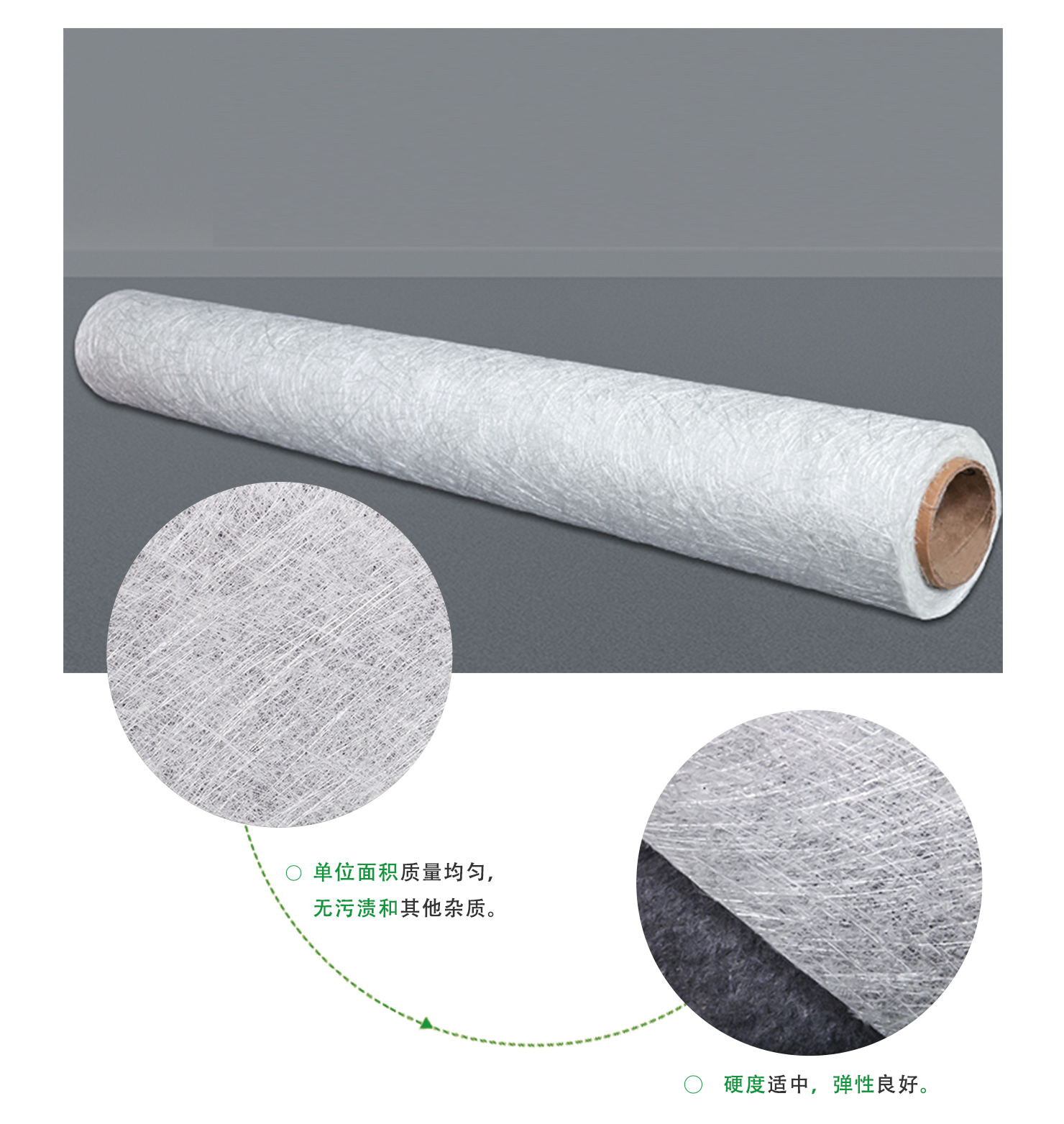

Fiberglass Chopped Strand Mat has earned its reputation as a cornerstone of composite manufacturing through a powerful combination of practicality and performance. Composed of randomly oriented glass filaments bonded together by a chemical binder, CSM is designed to be easily saturated with resin, creating a robust, homogeneous material upon curing. Its key advantage lies in its isotropic nature—providing uniform strength in all directions, which makes it exceptionally reliable for molding complex shapes and curved surfaces without weak points.

This characteristic has made CSM the material of choice for countless applications. In marine manufacturing, it forms the hulls and decks of boats, offering exceptional resistance to water and corrosion. In construction, it is used for building lightweight yet strong panels, roofing, and piping systems. The automotive industry relies on CSM for interior panels, truck cabins, and aftermarket components, thanks to its acoustic damping and impact resistance. Water treatment plants, swimming pools, and sanitary ware also depend heavily on CSM for its structural and water-resistant properties. Its adaptability across sectors underscores its irreplaceable role in global supply chains.

Next-Generation Advancements: Smarter, Stronger, and More Efficient

Recent innovations have elevated CSM from a basic reinforcement material to a high-performance solution tailored for specialized needs. Research in fiber chemistry has led to the development of acid-resistant and high-strength glass formulations, expanding CSM’s use in highly corrosive environments such as chemical storage tanks and exhaust systems. Binder technology has seen perhaps the most radical improvement: modern binders dissolve faster and more uniformly, speeding up production cycles and ensuring thorough resin infusion for fewer defects and higher consistency.

Automation has further enhanced quality and reduced waste. Computer-controlled forming and cutting systems now produce rolls of CSM with exceptionally even distribution of fibers and binder, resulting in higher predictability in finished composites. Some manufacturers have also introduced hybrid mats, which combine chopped strands with continuous or woven fabrics. These products offer the multidimensional stability of traditional CSM with the targeted strength of oriented fibers, opening up new possibilities in aerospace sub-components, high-performance automotive parts, and specialized sporting goods.

Green and Clean: Sustainability at the Heart of CSM Production

One of the most significant shifts in the CSM industry is its move toward sustainable production. Manufacturers are increasingly using recycled glass—often sourced from post-consumer and industrial waste—to produce eco-friendly CSM variants. This not only reduces reliance on raw materials but also lowers the energy required in manufacturing, shrinking the overall carbon footprint of composite products.

Moreover, the development of low-styrene and bio-based binders is improving workplace safety and reducing volatile organic compound (VOC) emissions during the lamination process. End-of-life recycling of CSM-based composites is also becoming more feasible through advanced separation techniques like pyrolysis, which allows glass and resin to be recovered and repurposed. These initiatives reflect a sector-wide commitment to circular economy principles, helping industries meet stricter environmental regulations and consumer demand for greener products.

Expanding Applications: Meeting the Needs of Tomorrow’s Markets

The improved performance and sustainability profile of contemporary CSM are opening doors to new and growing markets. In wind energy, CSM is used in the interior structures of turbine blades and nacelles, where its balance of strength and cost is essential for scaling renewable infrastructure. The electric vehicle (EV) sector is adopting CSM for battery enclosures and body panels, where light weight and safety are paramount.

In infrastructure, CSM is reinforcing polymer bridges and architectural elements, providing long service life with minimal maintenance. Even creative industries are benefiting—sculptors, designers, and set builders are using easier-handling CSM variants for creating durable, detailed artworks and exhibits. As global investment continues to grow in these areas, CSM is well-positioned to support innovation at scale.

Conclusion: Building a Stronger Future, Layer by Layer

Fiberglass Chopped Strand Mat has proven itself to be much more than a basic industrial material. Through continuous innovation and a firm commitment to sustainability, it remains essential to current manufacturing while enabling the technologies of the future. Its unique blend of versatility, performance, and eco-efficiency ensures that CSM will continue to be a critical material in creating durable, light, and sustainable solutions across the globe. As industries evolve, so too will CSM—strengthening everything it helps build.

Fiberglass Chopped Strand Mat,CSM,composites, isotropic strength,electric vehicles,corrosion resistance

Related news

2025-08-25

2025-08-22

7628 Electronic Fiberglass Fabric: The Ultimate Solution for High-Performance Electronics

2025-08-15