Welcome To Hebei Xiongan Hengyun Technology Co., Ltd.

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Revolution Under Wrap: Fiberglass Self-Adhesive Tape Strengthens Industries with a Simple Peel and Press

2025-08-22

In the bustling world of industrial materials and DIY solutions, true innovation is often measured not by complexity, but by simplicity and profound effectiveness. A quiet revolution is underway, one that is strengthening everything from pipelines to prosthetic limbs, and it comes on a roll. Fiberglass Self-Adhesive Tape, a sophisticated composite material once confined to specialized industrial applications, is now emerging as a game-changing solution across a breathtakingly wide spectrum of sectors. By marrying the immense tensile strength of fiberglass with the effortless application of a pressure-sensitive adhesive, this tape is redefining standards for repair, reinforcement, and creation, offering a potent combination of strength, convenience, and versatility that is capturing the attention of engineers, contractors, and innovators worldwide.

This isn't merely an upgrade to existing tape products; it's a paradigm shift. Traditional repair methods often involve messy resins, clamps, and lengthy curing times. Conventional reinforcement can mean heavy, bulky materials that are difficult to shape. Fiberglass Self-Adhesive Tape elegantly bypasses these complications, offering a clean, dry, and immediate solution that delivers exceptional performance the moment it is applied. From preventing corrosion on underwater structures to creating lightweight casts in sports medicine, its applications are as diverse as they are impressive. This article delves into the makeup of this remarkable material, explores its multifaceted applications, and examines the tangible economic and practical benefits it delivers, painting a picture of a future held firmly together by this advanced tape.

The Anatomy of an Innovation: What Exactly is Fiberglass Self-Adhesive Tape?

At its core, Fiberglass Self-Adhesive Tape is a masterclass in material engineering. It is a laminate composite typically consisting of three key components:

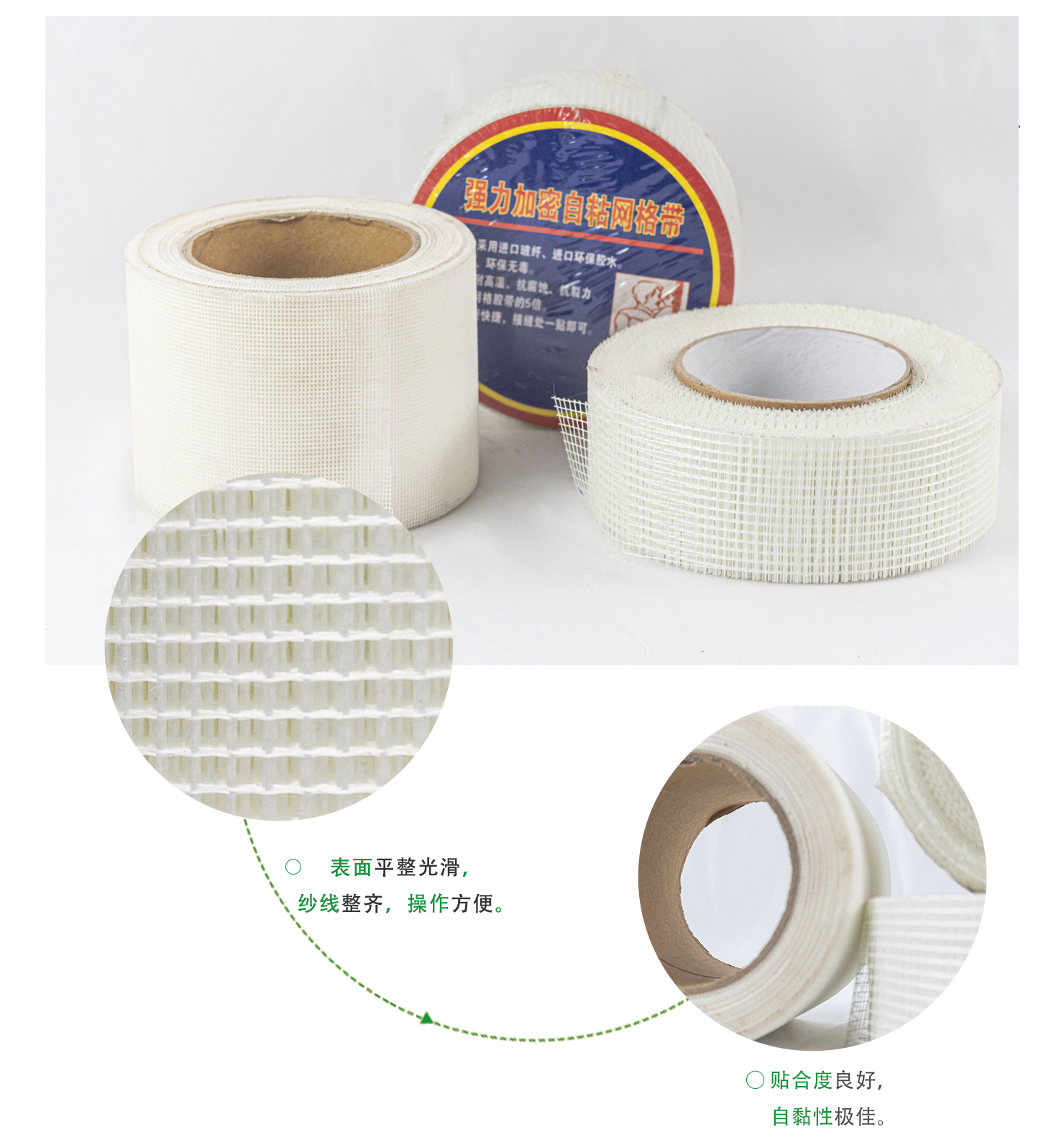

The Fiberglass Backing: The foundation of the tape is a woven fabric or unidirectional tape made from incredibly fine glass fibers. These fibers are known for their high tensile strength—meaning they are exceptionally resistant to pulling forces—while remaining lightweight and flexible. The weaving pattern can be designed for multidirectional strength or unidirectional force distribution, depending on the intended application. Crucially, fiberglass is also non-corrosive, non-conductive, and resistant to chemical degradation and extreme temperatures, making it suitable for harsh environments where metals would fail.

The Impregnated Resin System: The fiberglass mesh is pre-impregnated (pre-preg) with a specially formulated synthetic resin, most commonly a polyurethane or epoxy-based system. This resin is dormant and inert until activation. This is the "self-adhesive" magic. Unlike traditional fiberglass repairs that require manually mixing a liquid resin with a hardener, this tape has the resin ready to go, perfectly measured and evenly distributed throughout the fabric.

The Release Liner: A protective silicone-coated paper or plastic backing keeps the tape from sticking to itself on the roll and protects the adhesive layer from contamination and premature activation until it is ready for use.

The application process is deceptively simple: measure, cut, peel the liner, and wrap. Upon application, with exposure to air (for moisture-curing urethanes) or through the application of slight pressure and heat (for some epoxy systems), the resin system activates. It begins to cross-link and cure, transforming from a flexible, tacky tape into a rigid, high-strength, monolithic shell that is permanently bonded to the substrate. This process creates a composite structure that is often stronger than the original material it is repairing.

Peel, Stick, and Solve: Multisector Applications Reshaping Best Practices

The utility of Fiberglass Self-Adhesive Tape is not limited to a single field. Its unique properties have led to widespread adoption in numerous industries.

Construction and Infrastructure: Here, the tape is a powerhouse for concrete rehabilitation. It is used to seal and reinforce cracks in concrete pillars, beams, and floors, restoring structural integrity without the need for expensive and disruptive demolition and re-pouring. It is also extensively used for pipe repair, providing a high-strength, corrosion-resistant sleeve for pipelines carrying water, oil, and gas, effectively preventing leaks and extending service life by decades.

Marine and Automotive: In boat building and repair, the tape is indispensable. It is used to reinforce hull joints, repair decks, and secure fittings, all with a waterproof and salt-resistant bond. The automotive and aerospace industries utilize it for prototyping, reinforcing composite panels, and making swift, strong repairs to body kits, interior components, and even under-hood elements that experience high temperatures.

Sports Medicine and Orthopedics: A revolutionary application is in the creation of custom, lightweight medical casts and splints. Orthotists peel the tape, saturate it in water, and mold it directly onto a patient's limb. Within minutes, it hardens into a durable, breathable, and waterproof cast that is far superior to traditional plaster in terms of patient comfort and clinical utility. It's also used to fabricate bespoke supportive braces.

Electrical and General Industry: Its dielectric properties make it perfect for insulating and protecting electrical cables, connections, and conduits, particularly in demanding environments. Furthermore, it is a staple in warehouses and factories for general maintenance: bundling cables, reinforcing packaging, patching equipment housings, and even performing temporary repairs on machinery to prevent downtime until a permanent fix can be implemented.

The Tangible Advantage: Quantifying the Benefits of Adoption

The move towards Fiberglass Self-Adhesive Tape is driven by a compelling roster of benefits that directly impact the bottom line, safety, and efficiency.

Unmatched Ease of Use and Speed: The elimination of mixing pots, brushes, and messy liquids drastically reduces application time and skill barriers. Repairs that once took hours of preparation and curing can now be completed in minutes. This speed translates directly into reduced labor costs and minimized operational downtime, a critical factor for industries like manufacturing and transportation where every minute counts.

Superior Strength-to-Weight Ratio: The cured tape creates an incredibly strong shell that adds minimal weight. This is crucial in automotive and aerospace applications where every gram matters for fuel efficiency, and in medical applications where patient comfort is paramount.

Exceptional Durability and Longevity: Resistant to water, chemicals, UV radiation (with specific variants), and corrosion, repairs made with this tape are not just quick fixes; they are long-term solutions. This durability reduces the frequency of maintenance cycles and associated costs over the lifespan of an asset.

Enhanced Safety: The dry application system minimizes exposure to volatile organic compounds (VOCs) and toxic fumes associated with liquid resins. It also reduces slip hazards and skin irritation, creating a safer workspace.

Versatility and Cost-Effectiveness: One product can replace an entire inventory of specialized patching compounds, clamps, and heavy reinforcement materials. This simplifies supply chains, reduces inventory costs, and empowers technicians to handle a wider array of problems with a single, versatile tool.

The Future is Bound Tight: Conclusion and Forward Look

Fiberglass Self-Adhesive Tape is more than just a convenient product; it is a testament to how intelligent material science can simplify complexity and drive progress. It has democratized high-strength composite repair, putting capabilities that were once the domain of specialized technicians into the hands of many. As material scientists continue to innovate, we can expect to see tapes with even faster curing times, bio-based and more sustainable resins, enhanced flexibility for dynamic applications, and integrated smart technologies—perhaps with sensors to monitor the integrity of the repair itself.

The message from the market is clear: the future of repair, reinforcement, and innovative construction is leaning towards solutions that are smarter, cleaner, faster, and stronger. By offering a potent blend of these qualities in a simple, accessible format, Fiberglass Self-Adhesive Tape is not just participating in this future; it is actively binding it together, one peel-and-stick application at a time. Its continued adoption promises to build a world that is more resilient, efficient, and brilliantly simple to maintain.

Fiberglass tape,Self-adhesive,High-strength reinforcement,Composite repair,Corrosion-resistant,Pressure-sensitive adhesive,Industrial maintenance,Quick application

Related news

2025-08-22

7628 Electronic Fiberglass Fabric: The Ultimate Solution for High-Performance Electronics

2025-08-15

Revolutionizing Industrial Solutions: The Rise of Fiberglass Self-Adhesive Tape

2025-08-13