Welcome To Hebei Xiongan Hengyun Technology Co., Ltd.

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Revolutionizing Industrial Solutions: The Rise of Fiberglass Self-Adhesive Tape

2025-08-13

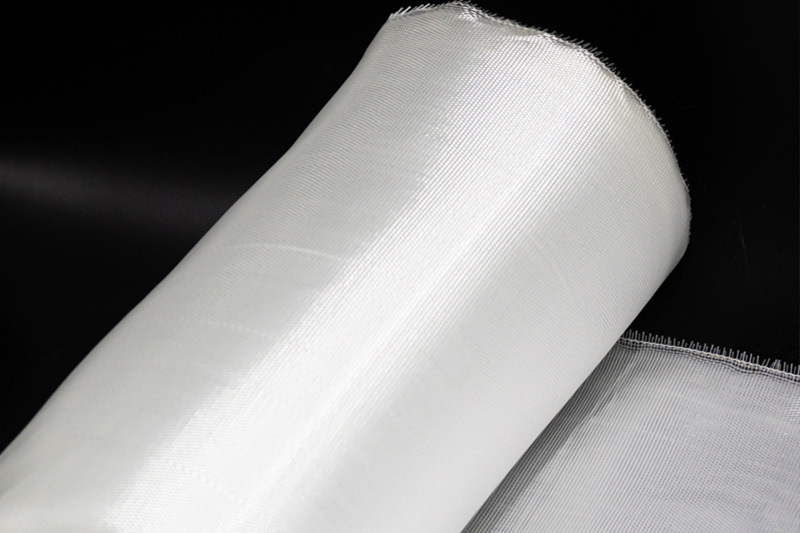

The global market for high-performance adhesive solutions is witnessing a significant shift with the growing adoption of fiberglass self-adhesive tape. This cutting-edge material is redefining standards in durability, heat resistance, and ease of use, making it indispensable in industries ranging from construction and automotive to electronics and renewable energy.

Unlike conventional adhesive tapes, fiberglass self-adhesive tape combines the strength of woven fiberglass with a high-performance adhesive backing, delivering unmatched reliability in demanding environments. Its rapid acceptance across sectors underscores its potential to become a staple in modern manufacturing and repair applications.

Understanding Fiberglass Self-Adhesive Tape: A Breakthrough in Material Science

Fiberglass self-adhesive tape is engineered with a robust fiberglass mesh core, coated with a pressure-sensitive adhesive that ensures strong, instant bonding. The fiberglass reinforcement provides exceptional tensile strength, while the adhesive layer offers a secure, residue-free hold.

Key Characteristics:

-

Exceptional Strength-to-Weight Ratio – Maintains structural integrity under stress without adding bulk.

-

Thermal Stability – Withstands extreme temperatures from -50°C to 260°C (-58°F to 500°F), making it ideal for high-heat applications.

-

Chemical & Moisture Resistance – Performs reliably in corrosive or humid environments.

-

Flexible Yet Non-Stretch – Conforms to irregular surfaces without losing adhesion.

-

Quick Application – Peel-and-stick functionality reduces installation time by up to 70% compared to liquid adhesives.

This unique combination of properties positions fiberglass self-adhesive tape as a superior alternative to traditional duct tapes, aluminum foils, and epoxy-based solutions.

Why Industries Are Switching to Fiberglass Self-Adhesive Tape

**1. Construction & Infrastructure: Reinventing Durability

In modern construction, the tape is revolutionizing:

-

Seismic reinforcement of drywall joints and concrete cracks.

-

Waterproofing membranes for roofs and basements.

-

HVAC system sealing, reducing energy leaks by 30%.

"We’ve cut project timelines by 25% since switching to fiberglass tape for drywall seams. Its fire resistance also simplifies compliance with safety codes," notes Emma Rodriguez, Site Supervisor at GreenBuild Contractors.

**2. Automotive & Aerospace: Lightweight Performance

-

Electric vehicle (EV) battery insulation – Prevents thermal runaway.

-

Aircraft interior panel bonding – Meets FAA flammability standards.

-

Exhaust system repairs – Withstands vibration and 500°F+ temperatures.

**3. Electronics & Energy: Precision Protection

-

PCB (printed circuit board) shielding against electromagnetic interference (EMI).

-

Solar panel junction box sealing – Extends lifespan in outdoor installations.

-

Wind turbine blade repair – Provides structural support without weight penalty.

Sustainability & Cost Benefits Driving Adoption

Beyond performance, fiberglass self-adhesive tape offers compelling economic and environmental advantages:

- Reduced Material Waste

Pre-cut tape eliminates overuse of liquid adhesives; 100% solvent-free options are available.

- Energy Efficiency

Thinner than metal repair tapes, it lowers shipping costs and carbon footprint.

- Long-Term Savings

A single application lasts 5–10 years, reducing maintenance frequency.

"Our solar farm maintenance costs dropped by 40% after adopting fiberglass tape for cable management," reports David Kim, CFO of SunPower Renewables.

The Future: Smart Integration & Expanded Applications

Manufacturers are now developing next-gen variants with:

-

Conductive adhesives for wearable tech integration.

-

Color-changing indicators to signal heat damage.

-

Biodegradable fiberglass for eco-sensitive sectors.

Dr. Lisa Hammond, Materials Scientist at MIT, predicts:

"Within a decade, fiberglass tapes could replace welded joints in lightweight manufacturing, saving billions in labor costs."

Conclusion: A Tape That’s Sticking Around

As industries prioritize efficiency, safety, and sustainability, fiberglass self-adhesive tape is proving to be more than a niche product—it’s a transformational tool. With ongoing R&D expanding its capabilities, this innovation is poised to become as ubiquitous as the screwdriver in the modern industrial toolkit.

Fiberglass tape,self-adhesive tape,industrial adhesive,high-temperature tape,construction reinforcement, automotive insulation, sustainable adhesive, heat-resistant tape,peel-and-stick solution

Related news

Revolutionizing Industrial Solutions: The Rise of Fiberglass Self-Adhesive Tape

2025-08-13

Fiberglass Cloth: The Unsung Hero of Modern Innovation

2025-08-11

Fiberglass Chopped Strand Mat: The Unsung Hero of Modern Manufacturing

2025-08-08