Welcome To Hebei Xiongan Hengyun Technology Co., Ltd.

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

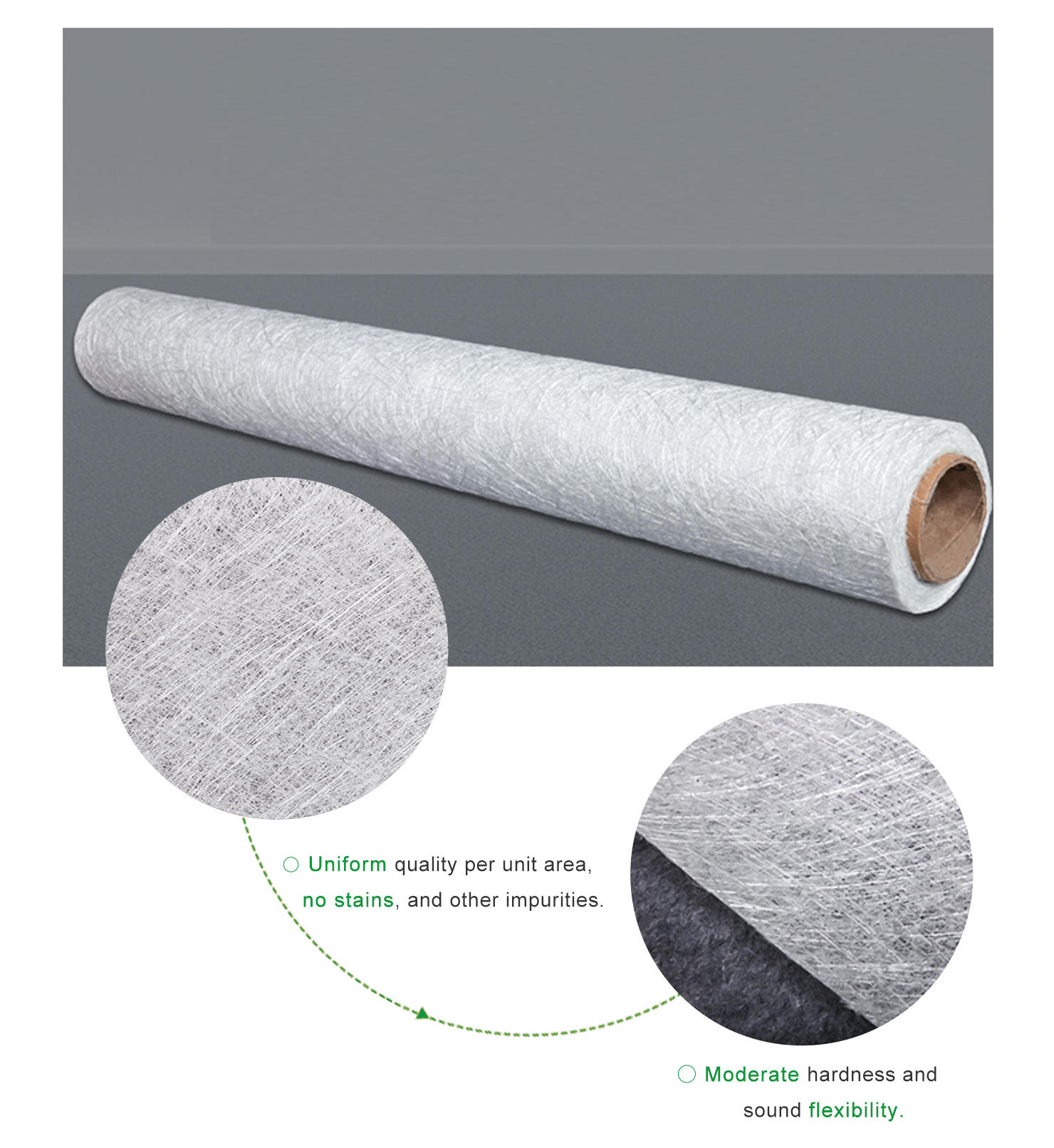

Fiberglass Chopped Strand Mat: The Unsung Hero of Modern Manufacturing

2025-08-08

The Quiet Revolution in Composite Materials

In factories and workshops around the world, a quiet revolution is taking place. Fiberglass Chopped Strand Mat (CSM), once considered a simple reinforcement material, is now emerging as a critical component in everything from electric vehicles to offshore wind farms. With its unique combination of strength, flexibility, and cost-effectiveness, CSM is helping manufacturers solve some of their toughest engineering challenges while meeting increasingly stringent sustainability requirements.

What Makes CSM Special?

At its core, Fiberglass Chopped Strand Mat is a marvel of materials engineering:

-

Random Fiber Orientation: Unlike woven fabrics with directional strength, CSM's randomly arranged fibers provide uniform reinforcement in all directions

-

Resin Compatibility: The soluble binder dissolves easily in polyester, vinyl ester, and epoxy resins, creating a strong, homogeneous composite

-

Formability: Can be easily molded into complex shapes that would challenge other reinforcement materials

Industry veteran Mark Richardson of Composite Solutions Inc. puts it simply: "CSM is the Swiss Army knife of composite reinforcement. There's hardly a project where we don't use it at some stage."

Industry Transformations Powered by CSM

1. The Green Energy Boom

The renewable energy sector has become one of the biggest consumers of CSM:

-

Wind Turbine Blades: CSM forms the structural backbone of many blade designs

-

Solar Panel Supports: Providing durable, weather-resistant frames

-

Hydroelectric Components: Standing up to constant water exposure

"Without CSM, we couldn't produce wind turbine blades at the scale and price point needed for the energy transition," says Dr. Elena Torres of GreenPower Technologies.

2. Marine Innovations

The marine industry has seen particular benefits:

-

Faster Boat Production: CSM's ease of use has shortened build times by up to 30%

-

Improved Durability: New formulations resist blistering and osmotic degradation

-

Custom Designs: Enables more complex hull shapes for performance sailing

3. Automotive Advancements

Electric vehicle manufacturers are turning to CSM for:

-

Battery enclosures

-

Lightweight body panels

-

Structural components

Tesla's recent patent filings reveal extensive use of CSM-based composites in their Cybertruck production.

The Sustainability Edge

In an era of environmental consciousness, CSM offers compelling advantages:

-

Longer Product Lifespans: CSM-reinforced products often outlast alternatives

-

Recyclability: New processes can recover glass fibers for reuse

-

Reduced Material Waste: Precise application minimizes scrap

The European Composites Industry Association reports that CSM use has grown 17% annually as manufacturers seek greener solutions.

Future Horizons

Emerging applications include:

-

3D Printed Composites: CSM-enhanced filaments for additive manufacturing

-

Smart Infrastructure: Self-monitoring bridges with embedded sensors in CSM matrices

-

Space Applications: Lightweight components for satellite systems

Material scientists at MIT recently demonstrated CSM composites with self-healing capabilities, potentially opening entirely new applications.

The Material That's Here to Stay

From backyard DIY projects to cutting-edge aerospace applications, Fiberglass Chopped Strand Mat continues to prove its worth. As manufacturing evolves toward more sustainable, efficient practices, CSM's unique combination of properties ensures it will remain a cornerstone material for decades to come.

"Twenty years ago, some predicted composites would replace CSM," reflects industry analyst James Kohler. "Instead, CSM made composites accessible to the world."

Fiberglass Chopped Strand Mat (CSM),composite materials, reinforcement, sustainability,wind turbines, marine applications,automotive industry,lightweight, resin compatibility,self-healing composites

Related news

Fiberglass Chopped Strand Mat: The Unsung Hero of Modern Manufacturing

2025-08-08

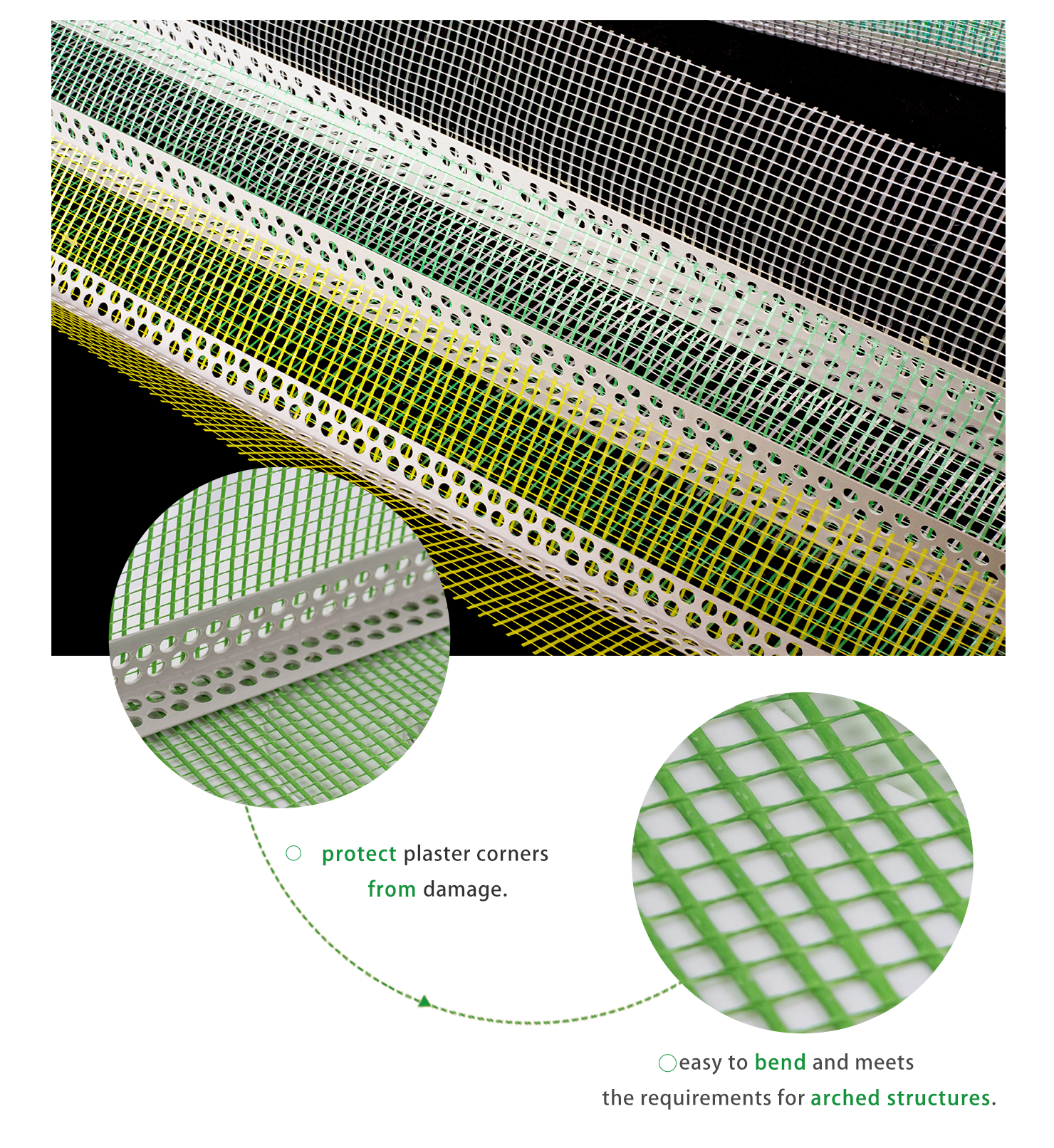

Fiberglass Corner Mesh: The Future of Stronger, Smarter Construction

2025-08-06

Fiberglass Mesh: A Versatile Wonder Transforming Industries Worldwide

2025-08-04