Welcome To Hebei Xiongan Hengyun Technology Co., Ltd.

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Fiberglass Mesh: A Versatile Wonder Transforming Industries Worldwide

2025-08-04

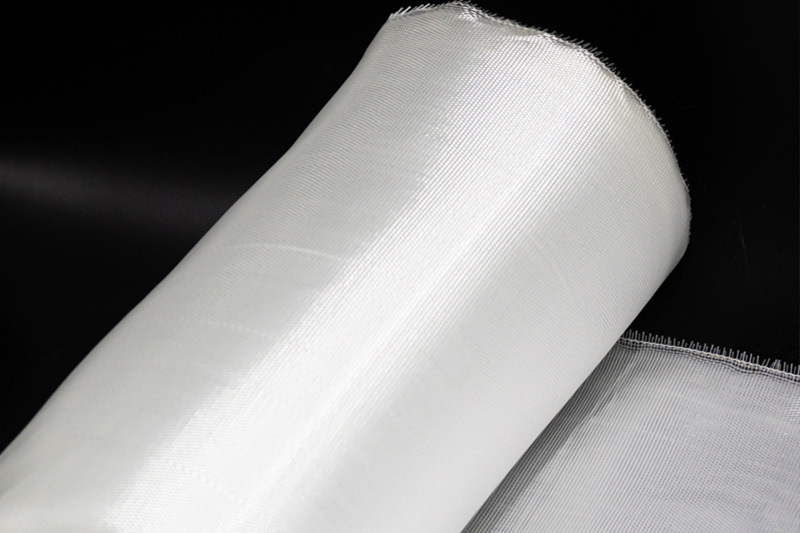

In the realm of modern materials science, few innovations have proven as adaptable and impactful as fiberglass mesh. Composed of interwoven glass fibers coated with specialized resins, this lightweight yet robust material has quietly revolutionized numerous sectors, offering solutions that balance strength, flexibility, and environmental responsibility. As industries worldwide seek more efficient and sustainable alternatives, fiberglass mesh emerges as a front-runner, driving progress in construction, agriculture, environmental protection, and beyond.

Revolutionizing Construction: Reinventing Structural Integrity

The construction industry has been one of the primary beneficiaries of fiberglass mesh technology. Traditional reinforcement materials like steel often face challenges such as corrosion, heavy weight, and high maintenance costs. Fiberglass mesh, however, addresses these issues head-on, providing a corrosion-resistant, lightweight alternative that significantly enhances the longevity of structures.

In building facades, fiberglass mesh is a key component in exterior insulation finishing systems (EIFS), where it reinforces the base coat, preventing cracks and ensuring the insulation layer remains intact even in extreme weather conditions. Builders in regions prone to earthquakes and hurricanes have particularly embraced this material, as its flexibility allows structures to absorb shocks without compromising stability. A recent project in coastal Florida, which utilized fiberglass mesh in its hurricane-resistant walls, withstood category 4 storm winds with minimal damage, showcasing the material’s exceptional performance under duress.

Moreover, the material’s ease of installation has reduced construction time and labor costs. Unlike steel, which requires heavy machinery for placement, fiberglass mesh can be cut and shaped on-site with simple tools, making it ideal for both large-scale commercial projects and small residential renovations. This efficiency has led to a 30% increase in its adoption in new construction projects across Europe and North America over the past five years, according to industry reports.

Boosting Agricultural Productivity: Protecting Crops and Enhancing Growth

Beyond construction, fiberglass mesh has found a vital role in agriculture, where it is transforming how farmers protect and nurture their crops. The material’s unique properties—including UV resistance, breathability, and durability—make it an excellent choice for crop covers, greenhouse screens, and trellising systems.

Farmers in arid regions use fiberglass mesh shade structures to reduce evaporation and protect delicate crops from scorching sunlight, resulting in yield increases of up to 40%. In pest-prone areas, the mesh acts as a physical barrier against insects and birds, reducing the need for chemical pesticides and promoting organic farming practices. A study conducted by the Agricultural Research Institute in Brazil found that farms using fiberglass mesh reported a 35% decrease in pesticide usage while maintaining or improving crop quality.

Additionally, fiberglass mesh trellises provide sturdy support for climbing plants like tomatoes, grapes, and beans, allowing for better air circulation and sunlight exposure. This not only improves crop health but also simplifies harvesting, as the plants grow in an organized manner. Small-scale farmers in Asia have particularly benefited, with many reporting higher profits due to increased yields and reduced losses from pests and harsh weather.

Advancing Environmental Sustainability: A Green Alternative

In an era where sustainability is a global priority, fiberglass mesh stands out as an eco-friendly material. Unlike traditional materials that rely on non-renewable resources or produce harmful emissions during manufacturing, fiberglass mesh is composed primarily of silica sand, a abundant natural resource. Its production process consumes less energy compared to steel or plastic alternatives, resulting in a lower carbon footprint.

Furthermore, fiberglass mesh is highly durable, with a lifespan of up to 50 years in some applications, reducing the need for frequent replacements and minimizing waste. When it does reach the end of its useful life, the material can be recycled, with specialized facilities able to process it into new fiberglass products or use it as a raw material in other industries. This closed-loop approach aligns with the principles of a circular economy, where resources are reused and waste is minimized.

The material’s contribution to energy efficiency is another environmental highlight. In construction, fiberglass mesh-reinforced insulation systems reduce heat transfer, lowering the energy consumption of buildings for heating and cooling. A study by the International Energy Agency estimates that widespread use of such systems could reduce global building energy consumption by 15% by 2030, a significant step toward mitigating climate change.

Driving Innovation: New Applications on the Horizon

As research and development in materials science continue, new and exciting applications for fiberglass mesh are emerging. In the automotive industry, manufacturers are exploring its use in lightweight body panels and interior components, aiming to reduce vehicle weight and improve fuel efficiency. Early prototypes have shown promising results, with fiberglass-reinforced parts offering comparable strength to steel at half the weight.

In the field of renewable energy, fiberglass mesh is being used in the construction of solar panel frames and wind turbine blades, where its resistance to corrosion and extreme temperatures ensures long-term reliability. Engineers are also experimenting with integrating the mesh into geotextiles for soil stabilization in infrastructure projects, such as road construction and riverbank reinforcement, where it can prevent erosion and improve soil structure.

The medical industry is even exploring fiberglass mesh for specialized applications, such as in orthopedic braces and surgical implants, due to its biocompatibility and strength. While these uses are still in the experimental stage, they highlight the material’s incredible versatility and potential to impact yet more sectors.

As we look to the future, fiberglass mesh continues to prove itself as a material of immense value, driving progress across industries while upholding principles of durability, efficiency, and sustainability. Its ability to adapt to diverse needs—from reinforcing skyscrapers to protecting crops—makes it a true wonder of modern materials science, and its positive impact is only set to grow.

Fiberglass Mesh, construction,agriculture,automotive industry,structural reinforcement

Related news

Fiberglass Mesh: A Versatile Wonder Transforming Industries Worldwide

2025-08-04

Fiberglass Self-Adhesive Tape: Revolutionizing Industries with Unmatched Performance and Versatility

2025-08-01

Fiberglass Cloth: A Catalyst for Innovation Across Industries

2025-07-30