Welcome To Hebei Xiongan Hengyun Technology Co., Ltd.

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

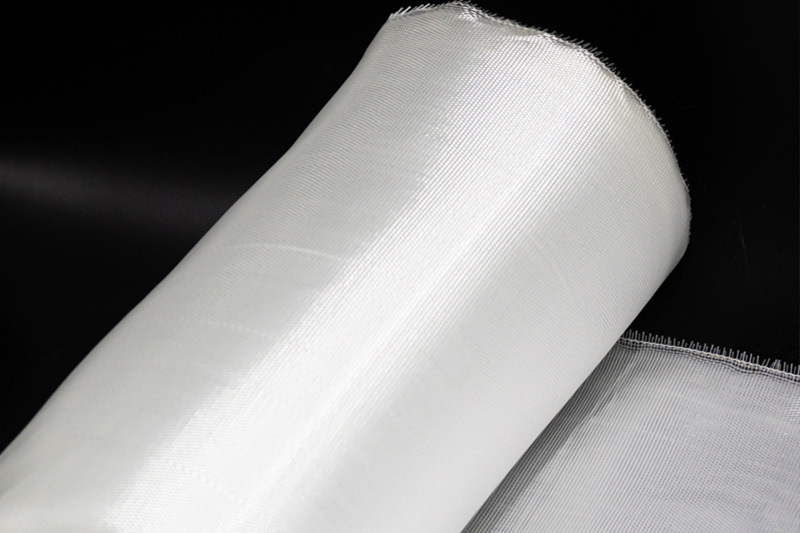

Fiberglass Cloth: A Catalyst for Innovation Across Industries

2025-07-30

Fiberglass cloth, crafted from ultra-fine glass filaments woven into durable fabric, has become a cornerstone of innovation across industries. Its blend of strength, versatility, and adaptability drives progress, enabling breakthroughs in design, efficiency, and sustainability, making it a go-to solution for evolving industry demands.

Unmatched Properties Driving Global Adoption

Fiberglass cloth’s success stems from its remarkable properties. Its unparalleled strength-to-weight ratio is key for weight-sensitive applications, revolutionizing product design. It resists extreme temperatures, performing reliably in scorching industrial settings and freezing aerospace conditions, expanding its use in automotive engine bays and high-temperature machinery.

Corrosion resistance makes it ideal for outdoor and marine use, as it withstands moisture, chemicals, and harsh weather, reducing replacements and costs—beneficial for sustainability. Its excellent electrical insulation safeguards sensitive electronics, ensuring smooth operation and enhancing safety.

Revolutionizing Key Industries

- Aerospace: Soaring to New Heights

The aerospace industry embraces fiberglass cloth for its lightweight nature, boosting aircraft fuel efficiency. Incorporated into wings, fuselages, and interiors, it reduces weight, cutting fuel use and emissions. Major manufacturers integrate fiberglass composites in new models, slashing weight significantly—lowering operational costs and aligning with carbon reduction goals. It also aids space exploration, used in satellite components to withstand extreme space conditions.

- Automotive: Driving Efficiency and Performance

In automotive, fiberglass cloth transforms vehicle design. Used in body panels, chassis, and interiors, it reduces weight while maintaining strength, enhancing acceleration, handling, and fuel economy. Electric vehicle makers value it for extending battery range; it also protects EV battery enclosures. Custom builders rely on its moldability for unique, aerodynamic parts, catering to enthusiasts.

- Construction: Building a Stronger Future

Construction benefits greatly from fiberglass cloth. As concrete and plaster reinforcement, it boosts tensile strength, reducing cracks in bridges, skyscrapers, and industrial facilities. Combined with resins, it forms seamless waterproof barriers for roofs and foundations, preventing water damage. As insulation, it regulates temperatures, cutting energy use. Sustainable projects prioritize it for long life and low maintenance, reducing repairs and waste.

- Marine: Navigating Toward Durability

The marine industry relies on fiberglass cloth for hulls, decks, and superstructures, thanks to its saltwater corrosion resistance and buoyancy. Fiberglass-reinforced boats are lighter than wood or steel ones, improving speed and maneuverability. They resist rot and rust, slashing maintenance, from small recreational boats to large commercial ships.

- Renewable Energy: Powering a Greener World

Fiberglass cloth impacts renewable energy. In wind energy, it’s used in turbine blades—its strength and flexibility enable large, efficient blades that capture more wind. Weather resistance ensures long lifespans. In solar energy, it constructs panel frames and mounts, with lightweight, corrosion-resistant properties ideal for outdoor installations, ensuring decades of functionality.

Advanced Manufacturing and Diverse Varieties

Fiberglass cloth production involves precise steps: melting glass, drawing filaments, spinning yarn, and weaving with advanced looms, creating customizable cloth. Various types exist: high-silica for extreme heat (industrial furnaces, aerospace shields), fireproof with flame-resistant coatings (safety equipment), chopped strand mat (moldable composites), woven roving (high strength), and multi-axial fabrics (enhanced reinforcement), suiting diverse needs.

A Promising Future Filled with Potential

The future of fiberglass cloth is bright. As industries prioritize sustainability, efficiency, and innovation, demand will grow. R&D enhances its properties—strength, flexibility—opening new applications. Advanced manufacturing makes it more accessible and cost-effective for small businesses. Eco-friendly production efforts align with global goals.

In conclusion, fiberglass cloth is indispensable in modern manufacturing and construction. Its unique properties, wide applications, and sustainability contributions drive innovation. As technology advances, it will further transform industries, enabling a more efficient, durable, and sustainable future.

High strength-to-weight ratio ,High strength-to-weight ratio ,Industry applications, Improved battery life ,Hull Structure ,Future Trends

Related news

Fiberglass Cloth: A Catalyst for Innovation Across Industries

2025-07-30

7628 Electronic Fiberglass Fabric: A Pivotal Material in the Modern Technological Landscape

2025-07-28

Fiberglass Roving Industry: Innovation, Expansion, and Market Trends

2025-07-25