Welcome To Hebei Xiongan Hengyun Technology Co., Ltd.

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

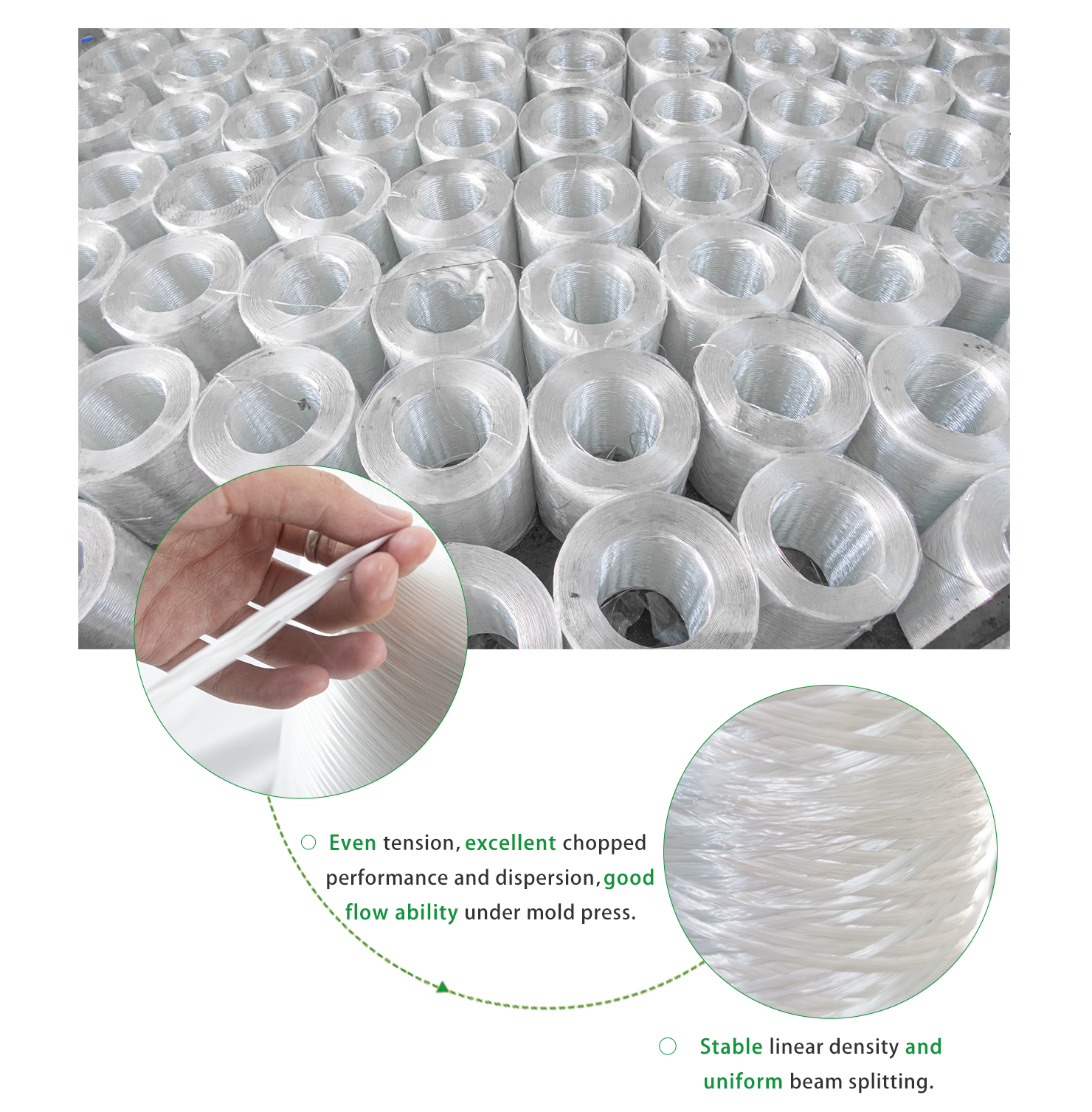

Fiberglass Roving Industry: Innovation, Expansion, and Market Trends

2025-07-25

The fiberglass roving industry is booming, fueled by tech progress, rising demand across sectors, and a focus on sustainable, high-performance materials. As a key part of composite production, it’s vital in construction, automotive, aerospace, and renewable energy.

Technological Breakthroughs

Manufacturing tech in fiberglass roving is advancing rapidly. Firms invest in R&D to boost production, creating higher-quality products. Better fiber drawing makes roving with uniform diameters and stronger tensile strength, enhancing composite durability and environmental resistance.

New coating technologies improve compatibility with resins. Specialized silane coatings, for example, strengthen adhesion and protect against moisture and corrosion, making composites more reliable.

Expanding Applications

Applications for fiberglass roving are growing fast. In construction, it’s used in high-strength, lightweight materials like FRP beams and columns, reducing building weight and boosting energy efficiency and seismic resistance.

The automotive industry relies on it for lightweight parts—bodies, bumpers, interiors—to cut vehicle weight, improve fuel economy, and enhance safety via better impact resistance.

Renewable energy, especially wind power, is a big market. Wind turbine blades, needing strength and lightness, use fiberglass roving, with demand set to soar as clean energy grows.

Global Expansion

Companies are expanding globally. China, a major player, adds capacity with advanced plants for competitive, quality roving. Asia’s India and Thailand attract investment for skilled labor, low costs, and growing markets.

Africa is emerging too. Egypt, rich in quartz and limestone, hosts Jushi Egypt’s plant (340,000 tonnes/year), making it Africa’s top and the world’s fourth-largest fiberglass producer.

Sustainability Steps

The industry is going green. Efforts to cut energy use, waste, and develop eco-friendly materials are underway. Some use recycled glass to reduce virgin material needs and carbon footprints. Work on biodegradable resins for use with roving is also progressing.

Challenges and Outlook

Challenges include fluctuating raw material and energy prices, plus intense global competition demanding constant innovation.

Yet the future is bright. With end-use industries growing and demand for sustainable, high-performance materials rising, fiberglass roving demand will climb. Tech advances will drive better, greener products. Global expansion into new markets ensures the industry will grow, aiding economic development and a sustainable future.

In conclusion, innovation, expansion, and sustainability are shaping the fiberglass roving industry. Its role across sectors will keep it key to global progress and the shift to sustainability.

market demand,production capacity,automotive sector,sustainable materials,global expansion,composite materials,technological advancements,fiberglass roving

Related news

Fiberglass Roving Industry: Innovation, Expansion, and Market Trends

2025-07-25

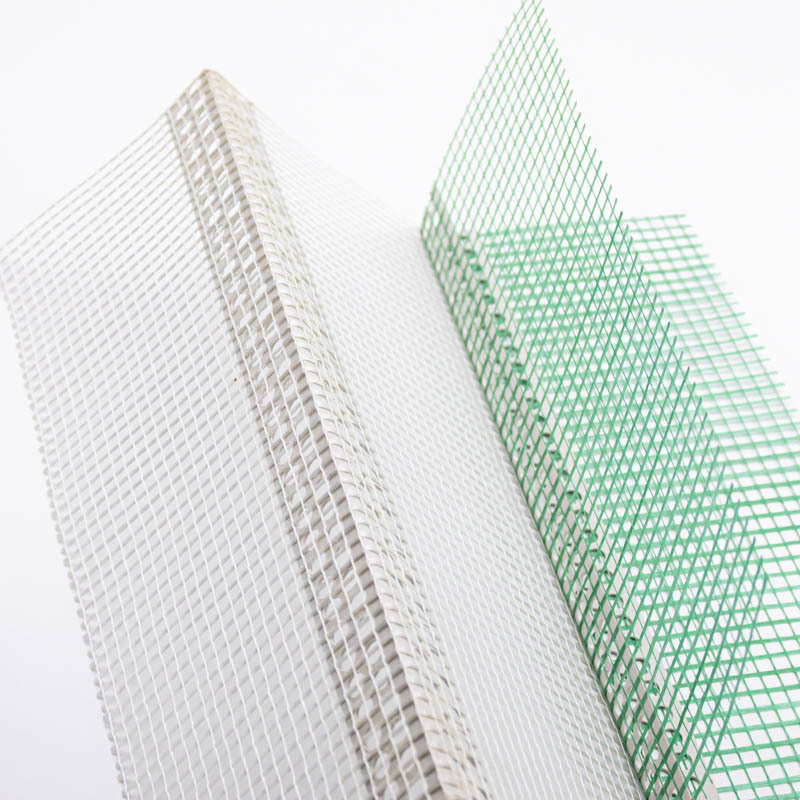

Fiberglass Corner Mesh: Revolutionizing Construction with Durability and Precision

2025-07-23

Fiberglass Mesh: The Revolutionary Material Reshaping Global Construction and Renovation Standards

2025-07-21