Welcome To Hebei Xiongan Hengyun Technology Co., Ltd.

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Fiberglass Corner Mesh: Revolutionizing Construction with Durability and Precision

2025-07-23

Introduction

The construction industry is constantly evolving, with new materials and technologies emerging to improve efficiency, durability, and cost-effectiveness. One such innovation is Fiberglass Corner Mesh, a lightweight yet robust solution designed to reinforce corners and edges in plastering, stucco, and rendering applications. As builders and contractors seek more reliable alternatives to traditional metal meshes, fiberglass corner mesh is gaining traction for its corrosion resistance, flexibility, and ease of installation.

This article explores the benefits, applications, and future potential of fiberglass corner mesh, highlighting why it has become a preferred choice in modern construction projects.

What is Fiberglass Corner Mesh?

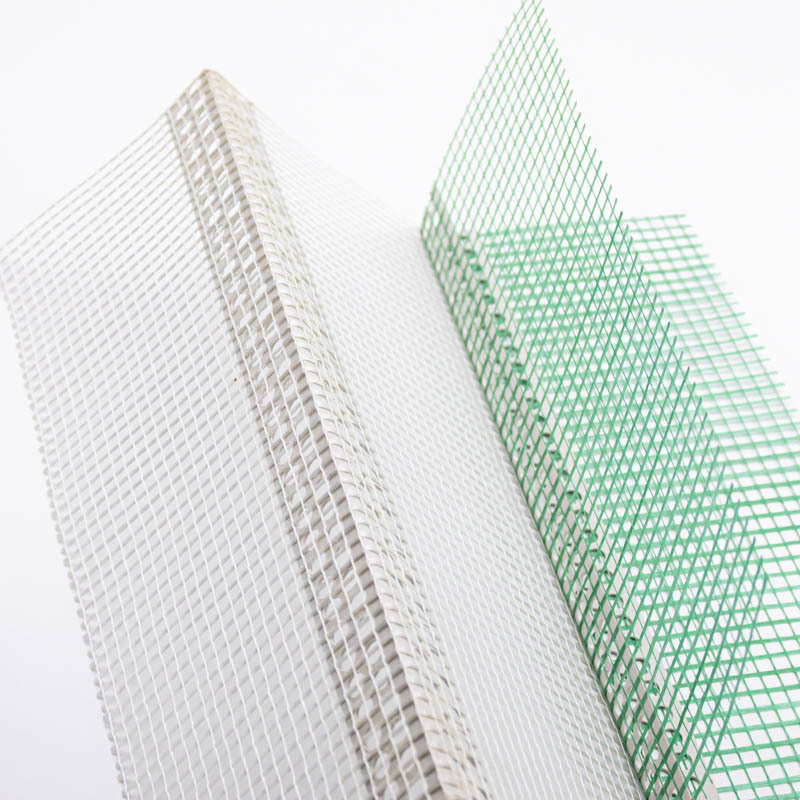

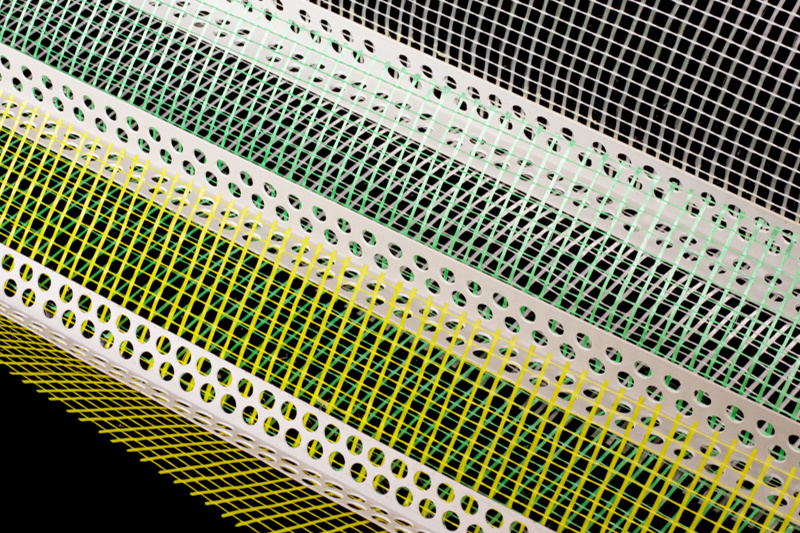

Fiberglass corner mesh is a specialized reinforcement material made from woven fiberglass strands coated with an alkali-resistant polymer. It is primarily used to protect and strengthen the corners of walls, ceilings, and other architectural features where cracks and structural weaknesses commonly occur.

Unlike traditional metal corner beads, fiberglass mesh does not rust, bend, or corrode over time. Its flexibility allows for seamless application on curved surfaces, making it ideal for both interior and exterior construction projects.

Key Advantages of Fiberglass Corner Mesh

1. Superior Durability and Crack Resistance

One of the most significant benefits of fiberglass corner mesh is its ability to prevent cracks caused by thermal expansion, settling, and moisture exposure. The alkali-resistant coating ensures long-term performance, even in harsh weather conditions.

2. Lightweight and Easy to Install

Compared to metal alternatives, fiberglass mesh is lightweight, reducing labor costs and installation time. It can be easily cut and shaped to fit various angles, allowing for precise application without specialized tools.

3. Corrosion and Rust Resistance

Unlike steel corner beads, fiberglass mesh does not corrode when exposed to water or alkaline materials like cement and plaster. This makes it an excellent choice for bathrooms, swimming pools, and coastal buildings.

4. Flexibility for Complex Designs

Fiberglass mesh adapts to curved and irregular surfaces, providing consistent reinforcement where rigid metal beads would fail. This flexibility is particularly valuable in modern architectural designs featuring rounded walls and custom shapes.

5. Cost-Effective Solution

While the initial cost may be comparable to metal options, fiberglass corner mesh reduces long-term maintenance expenses by minimizing repairs due to cracking or rust damage.

Applications of Fiberglass Corner Mesh

1. Drywall and Plastering

Fiberglass corner mesh is widely used in drywall installations to reinforce corners and prevent damage from impacts or settling. It ensures smooth, clean edges that resist cracking over time.

2. Exterior Insulation and Finish Systems (EIFS)

In EIFS applications, fiberglass mesh provides essential reinforcement for stucco and synthetic finishes, enhancing weather resistance and structural stability.

3. Tile and Stone Work

When installing tiles or stone veneers, fiberglass mesh helps secure edges and transitions, reducing the risk of chipping or separation.

4. Concrete and Masonry

For concrete structures, fiberglass mesh reinforces corners and joints, preventing cracks caused by shrinkage or seismic activity.

Future Trends and Market Growth

The global construction industry is increasingly adopting fiberglass corner mesh due to its sustainability and performance advantages. As green building practices gain momentum, the demand for non-corrosive, long-lasting materials will continue to rise.

Manufacturers are also developing self-adhesive fiberglass meshes and fire-resistant variants, further expanding their applications in high-rise buildings and fire-prone areas.

Conclusion

Fiberglass corner mesh represents a significant advancement in construction reinforcement technology. Its durability, ease of use, and resistance to environmental factors make it an indispensable material for modern builders. As the industry shifts toward more sustainable and efficient solutions, fiberglass corner mesh is poised to become a standard in both residential and commercial construction.

For contractors and architects seeking a reliable, cost-effective way to enhance structural integrity, fiberglass corner mesh offers a forward-thinking solution that meets the demands of today’s dynamic construction landscape.

Fiberglass corner mesh,Construction reinforcement,Crack prevention,Plaster reinforcement,Stucco reinforcement,Corrosion-resistant building materials,Lightweight construction materials,Flexible corner bead,Sustainable building materials,Masonry crack control

Related news

Fiberglass Roving Industry: Innovation, Expansion, and Market Trends

2025-07-25

Fiberglass Corner Mesh: Revolutionizing Construction with Durability and Precision

2025-07-23

Fiberglass Mesh: The Revolutionary Material Reshaping Global Construction and Renovation Standards

2025-07-21