Welcome To Hebei Xiongan Hengyun Technology Co., Ltd.

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Fiberglass Mesh: The Revolutionary Material Reshaping Global Construction and Renovation Standards

2025-07-21

Across the globe, a quiet revolution is taking place in the construction and renovation sectors, driven by the widespread adoption of fiberglass mesh. This advanced material, once considered a niche product, is now at the forefront of modern building solutions, offering unparalleled strength, flexibility, and resistance to environmental stressors. As urban development accelerates and the demand for sustainable construction materials rises, fiberglass mesh is rapidly becoming the go-to choice for engineers, contractors, and even homeowners undertaking DIY projects.

Understanding Fiberglass Mesh: A Modern Marvel in Material Science

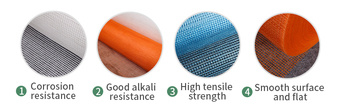

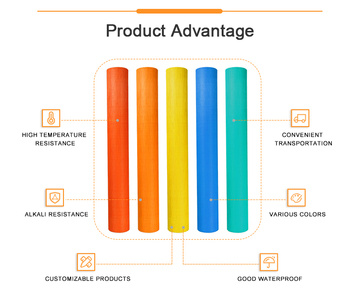

Fiberglass mesh is a high-performance reinforcing fabric composed of finely woven fiberglass strands, typically coated with an alkali-resistant compound to enhance its durability in harsh conditions. Unlike traditional reinforcement materials such as metal lath or wire mesh, fiberglass mesh is remarkably lightweight yet offers superior tensile strength. This unique combination of properties makes it exceptionally versatile, suitable for a wide range of applications—from exterior insulation systems to interior wall finishing.

One of the standout features of fiberglass mesh is its ability to adapt to complex surfaces. Whether applied to curved walls, uneven substrates, or high-stress areas, the material conforms seamlessly, reducing installation time and labor costs. Additionally, its resistance to moisture, corrosion, and extreme temperature fluctuations ensures long-term performance, even in challenging climates.

Why Fiberglass Mesh is Gaining Global Traction

The surge in popularity of fiberglass mesh can be attributed to several key advantages:

-

Superior Crack Resistance – Structural movement, settling, and thermal expansion are common causes of cracks in buildings. Fiberglass mesh acts as a reinforcement layer, distributing stress evenly and significantly reducing the risk of cracks in plaster, stucco, and concrete applications.

-

Ease of Installation – Unlike rigid alternatives, fiberglass mesh is flexible and easy to handle. It can be cut to size on-site and applied with standard adhesives or embedded in mortar, streamlining the construction process.

-

Eco-Friendly and Non-Toxic – As the construction industry shifts toward greener practices, fiberglass mesh stands out as an environmentally responsible option. Made from inorganic materials, it does not emit harmful volatile organic compounds (VOCs) and is fully recyclable at the end of its lifecycle.

-

Cost Efficiency – While the initial cost may be comparable to traditional materials, fiberglass mesh’s longevity and low maintenance requirements translate into significant savings over time. Its durability reduces the need for frequent repairs, making it a cost-effective solution for both large-scale projects and residential use.

-

Diverse Applications Across Industries

The versatility of fiberglass mesh has led to its adoption in a variety of sectors:

-

Exterior Insulation and Finish Systems (EIFS) – Fiberglass mesh is a critical component in EIFS, providing structural integrity and weather resistance to building facades.

-

Interior Renovations – From reinforcing drywall seams to preventing cracks in plaster, fiberglass mesh ensures smooth, long-lasting finishes in homes and commercial spaces.

-

Tile and Stone Installations – In wet areas like bathrooms and kitchens, fiberglass mesh serves as a stable backing for tiles, preventing displacement and water damage.

-

Infrastructure Projects – Bridges, tunnels, and highways benefit from fiberglass mesh’s ability to reinforce concrete and prevent cracking under heavy loads.

Market Growth and Future Innovations

The global fiberglass mesh market is experiencing robust growth, with analysts projecting a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This expansion is fueled by rapid urbanization, increased infrastructure spending, and a growing emphasis on energy-efficient buildings.

Emerging trends are further enhancing the material’s appeal:

-

Self-Adhesive Meshes – New variants with pre-applied adhesives simplify installation, making them ideal for quick repairs and DIY projects.

-

Fire-Resistant Coatings – Innovations in fireproof treatments are expanding fiberglass mesh’s use in high-risk environments, such as industrial facilities and high-rise buildings.

-

Smart Mesh Technology – Research is underway to integrate sensors into fiberglass mesh, enabling real-time monitoring of structural health in buildings and infrastructure.

Expert Perspectives on the Future of Fiberglass Mesh

Industry leaders are bullish about the material’s potential. According to John Carter, a senior construction specialist at BuildTech Solutions, "Fiberglass mesh is no longer just an alternative—it’s becoming the industry standard. Its adaptability, combined with its performance under stress, makes it indispensable for modern construction. We’re seeing a surge in demand, particularly in regions prone to seismic activity, where crack prevention is critical."

Similarly, Dr. Emily Roberts, a materials scientist at GreenBuild Innovations, highlights its sustainability benefits: "As regulators push for greener building codes, fiberglass mesh offers a viable solution. Its durability reduces waste, and its recyclability aligns perfectly with circular economy principles."

Conclusion: Building a Stronger, More Sustainable Future

As the construction industry evolves, fiberglass mesh is poised to play an increasingly vital role in shaping resilient, efficient, and sustainable structures. From skyscrapers to suburban homes, its applications are limitless, and ongoing innovations promise to unlock even greater potential.

For contractors, architects, and homeowners alike, fiberglass mesh represents not just a material choice—but a forward-thinking investment in the future of building.

Fiberglass mesh,construction material,crack prevention,sustainable building,construction innovation,lightweight construction material, durable building solutions,construction industry trends, building reinforcement

Related news

Fiberglass Mesh: The Revolutionary Material Reshaping Global Construction and Renovation Standards

2025-07-21

Fiberglass Chopped Strand Mat: A Versatile Reinforcement Material Driving Industry Growth

2025-07-16

Fiberglass Corner Mesh: Revolutionizing Construction with Durability and Efficiency

2025-07-14