Welcome To Hebei Xiongan Hengyun Technology Co., Ltd.

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Fiberglass Chopped Strand Mat: A Versatile Reinforcement Material Driving Industry Growth

2025-07-16

Introduction

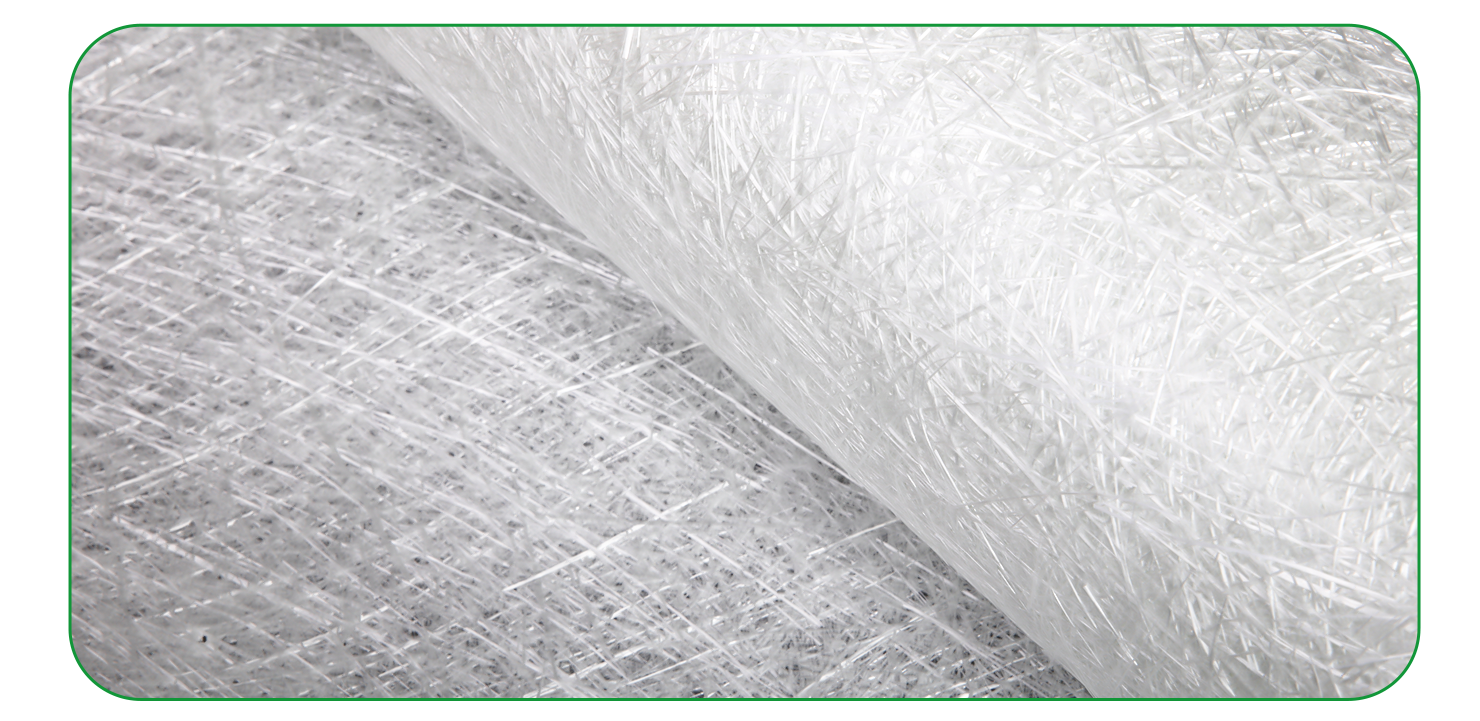

Fiberglass Chopped Strand Mat (CSM) is a non-woven material made from randomly distributed glass fibers held together by a resin-soluble binder. It is a preferred reinforcement choice for composite manufacturing processes such as hand lay-up, spray-up, resin transfer molding (RTM), and vacuum infusion. Due to its ease of use, affordability, and excellent mechanical properties, CSM is a staple in industries requiring lightweight yet durable materials.

The growing emphasis on fuel efficiency, corrosion resistance, and sustainable construction has further amplified the demand for fiberglass CSM. Manufacturers are continuously innovating to enhance its performance, making it a critical component in modern engineering applications.

Manufacturing Process

The production of Fiberglass Chopped Strand Mat involves several key stages:

-

Glass Melting & Fiber Formation

-

Raw materials (silica sand, limestone, soda ash) are melted in a furnace at high temperatures.

-

The molten glass is extruded through fine bushings to form continuous filaments.

-

-

Chopping & Mat Formation

-

The filaments are chopped into strands typically ranging from 25mm to 50mm in length.

-

These strands are randomly dispersed onto a conveyor belt to form a uniform, non-woven mat.

-

-

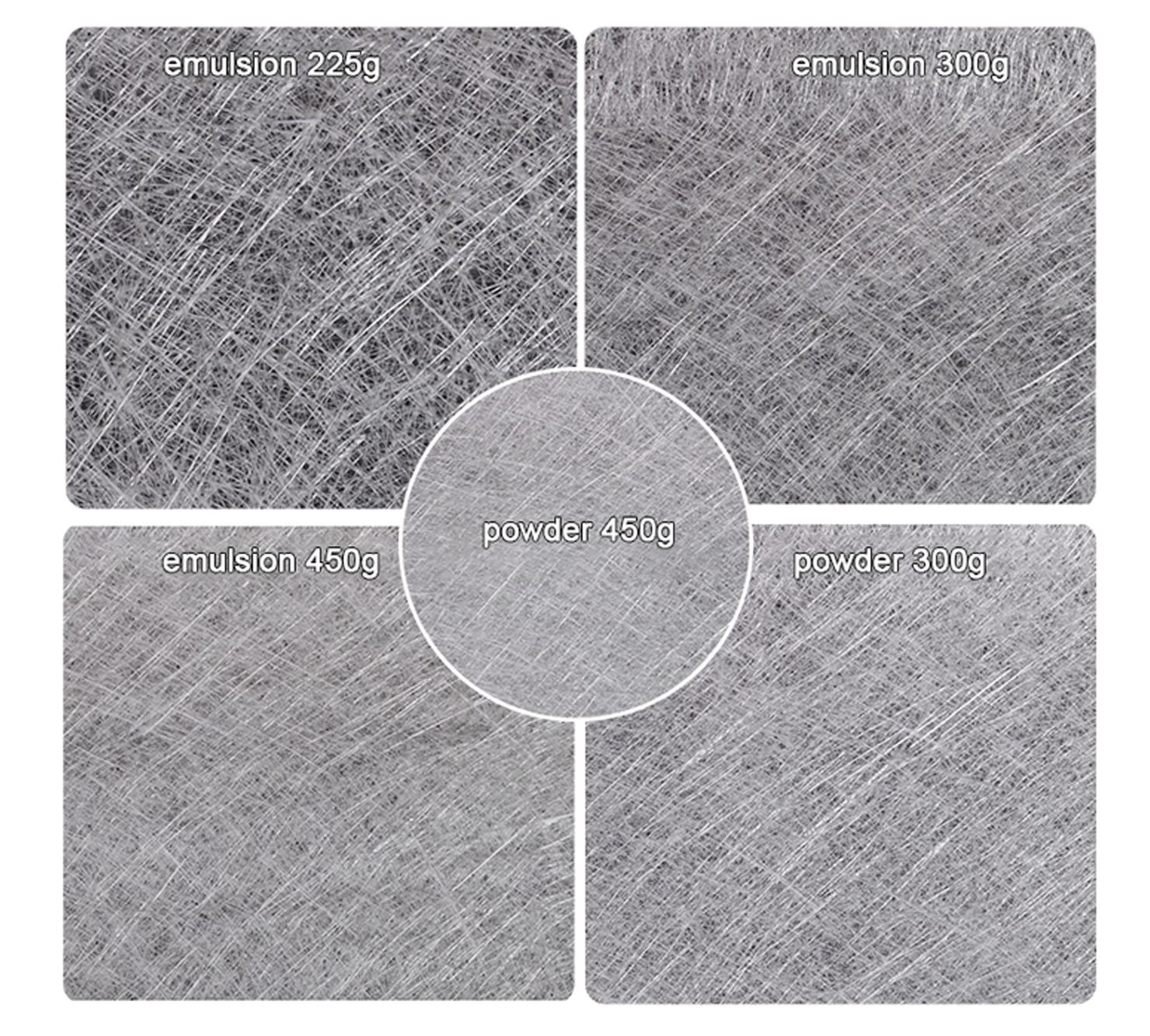

Binder Application & Curing

-

A powdered or liquid binder (usually polyester or epoxy-compatible) is applied to bond the fibers.

-

The mat passes through an oven to cure the binder, ensuring structural integrity.

-

-

Rolling & Packaging

-

The final product is rolled into large sheets and packaged for shipment.

-

Recent advancements include eco-friendly binders and recycled glass fibers, aligning with global sustainability goals.

Key Properties of Fiberglass CSM

Fiberglass Chopped Strand Mat offers several advantages that make it indispensable in composite manufacturing:

-

High Strength-to-Weight Ratio – Provides structural reinforcement without adding excessive weight, crucial for automotive and aerospace applications.

-

Excellent Corrosion Resistance – Ideal for marine, chemical, and wastewater treatment applications where metal alternatives would degrade.

-

Cost-Effectiveness – More affordable than woven fabrics while still delivering strong mechanical properties.

-

Ease of Handling & Compatibility – Works well with polyester, vinyl ester, and epoxy resins, making it versatile for different fabrication methods.

-

Impact Resistance – Enhances durability in products like automotive panels and boat hulls.

Applications Across Industries

1. Construction & Infrastructure

Fiberglass CSM is extensively used in:

-

Roofing & Cladding – Provides waterproofing and UV resistance.

-

Pipes & Tanks – Used in chemical storage and sewage systems due to corrosion resistance.

-

Composite Panels – Lightweight yet strong alternative to traditional building materials.

2. Automotive & Transportation

-

Body Panels & Bumpers – Reduces vehicle weight, improving fuel efficiency.

-

Interior Components – Reinforces dashboards, door panels, and trunk linings.

-

Electric Vehicles (EVs) – Increasingly used in battery enclosures for thermal and structural stability.

3. Marine Industry

-

Boat Hulls & Decks – Resists water absorption and marine degradation.

-

Repair & Maintenance – Commonly used for patching and reinforcing damaged fiberglass structures.

4. Wind Energy

-

Turbine Blades – Provides the necessary strength and flexibility to withstand high wind loads.

5. Industrial & Chemical Processing

-

Chemical Tanks & Ducting – Withstands harsh acids and solvents better than metal alternatives.

Market Trends & Future Outlook

The global Fiberglass Chopped Strand Mat market is projected to grow at a CAGR of 5.2% from 2023 to 2030, driven by:

-

Sustainability Initiatives – Development of bio-based binders and recycled glass fibers.

-

Lightweighting in Automotive & Aerospace – Stricter emissions regulations push demand for composite materials.

-

Infrastructure Boom in Emerging Economies – Increased construction in Asia-Pacific and the Middle East fuels demand.

-

Technological Advancements – Automation in mat production improves consistency and reduces costs.

Challenges include competition from alternative materials like carbon fiber and the need for improved recyclability. However, ongoing R&D is expected to address these issues, ensuring CSM remains a dominant reinforcement material.

Conclusion

Fiberglass Chopped Strand Mat is a cornerstone of modern composite manufacturing, offering unmatched versatility, strength, and cost-efficiency. As industries continue to prioritize lightweight, durable, and sustainable materials, CSM will remain a critical component in construction, automotive, marine, and renewable energy applications. With ongoing innovations in eco-friendly production and advanced composites, the future of Fiberglass CSM looks brighter than ever.

Chopped Strand Mat,Composite Materials, Construction, Automotive,Manufacturing, Lightweight Materials,Marine,Reinforcement,Resin Infusion,Sustainability,Wind Energy,Corrosion Resistance

Related news

Fiberglass Chopped Strand Mat: A Versatile Reinforcement Material Driving Industry Growth

2025-07-16

Fiberglass Corner Mesh: Revolutionizing Construction with Durability and Efficiency

2025-07-14

7628 Electronic Fiberglass Fabric: The Backbone of Modern High-Performance Electronics

2025-07-10