Welcome To Hebei Xiongan Hengyun Technology Co., Ltd.

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

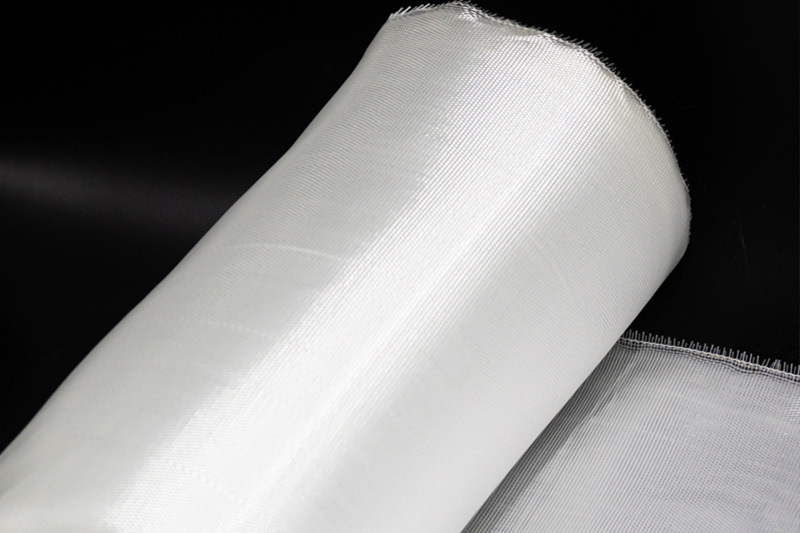

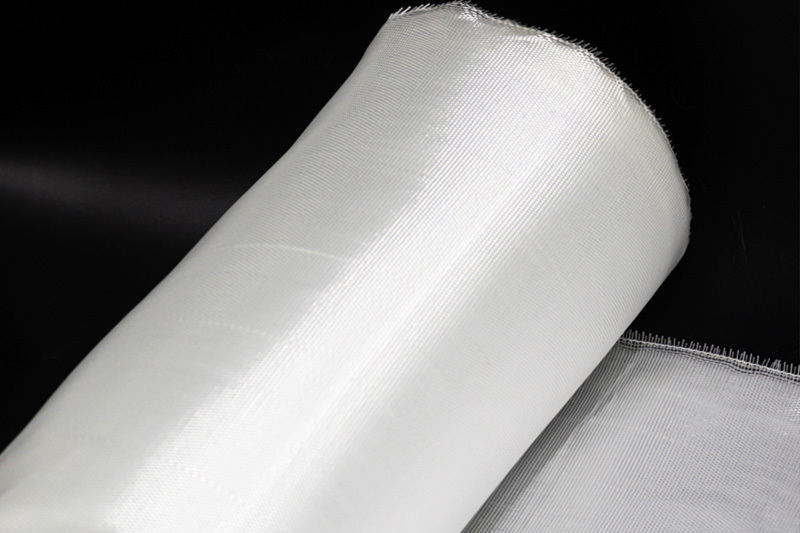

7628 Electronic Fiberglass Fabric: The Backbone of Modern High-Performance Electronics

2025-07-10

The Critical Role of 7628 Fiberglass Fabric in Modern Technology

In today’s rapidly evolving technological landscape, advanced materials play a pivotal role in enabling innovation. Among these, 7628 electronic fiberglass fabric has gained significant traction as a foundational material in electronics, aerospace, and automotive applications. Known for its high dielectric strength, thermal resistance, and mechanical durability, this specialized fabric is reshaping industries that demand reliability under extreme conditions.

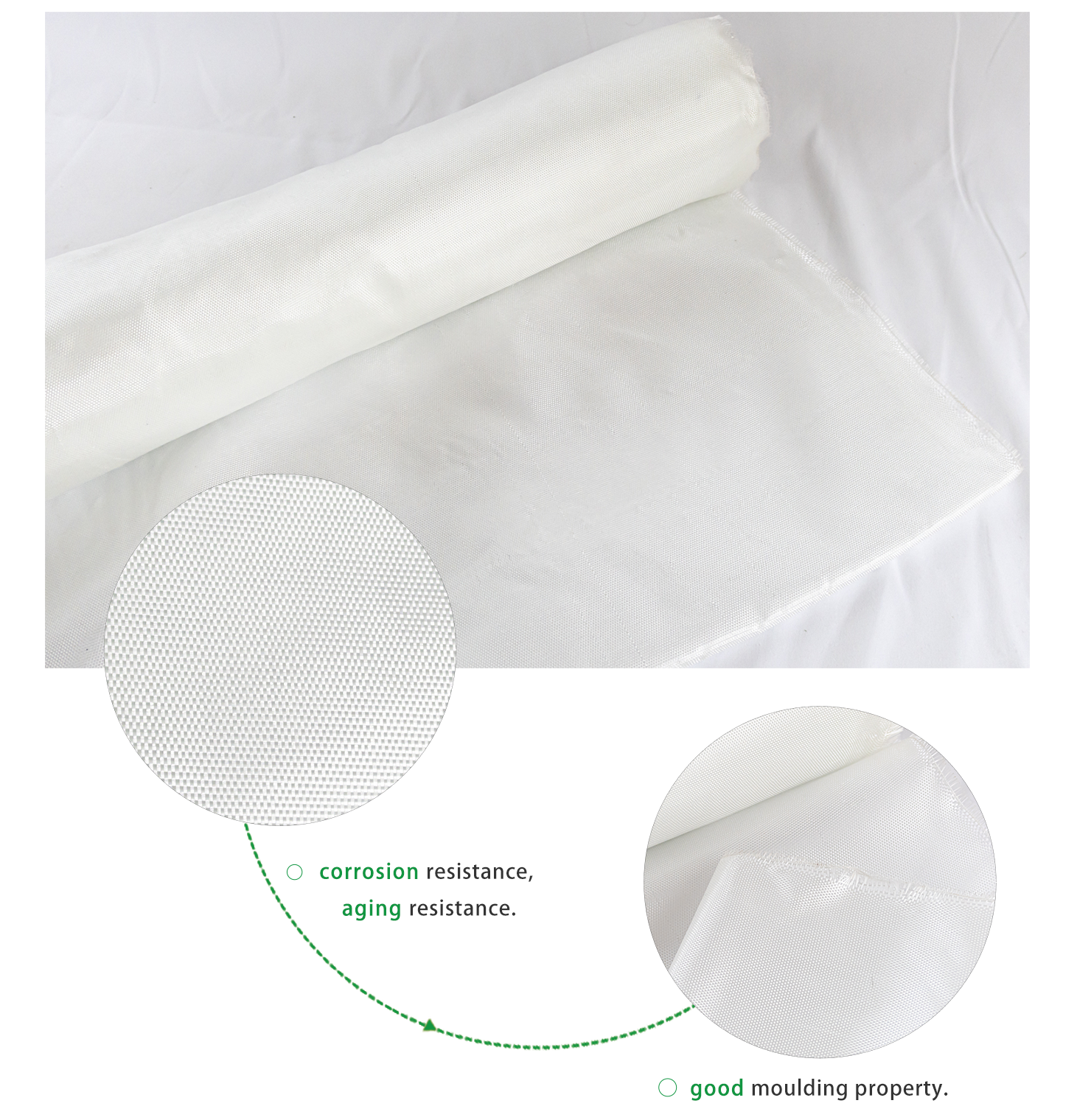

Unmatched Material Properties

7628 fiberglass fabric is woven from E-glass yarns, which provide an optimal balance of flexibility and rigidity. The plain weave construction ensures uniform resin absorption, making it ideal for multilayer PCB fabrication and composite reinforcement. Key properties include:

-

High Thermal Endurance – Capable of withstanding temperatures up to 600°C, making it suitable for aerospace and automotive applications where heat resistance is crucial.

-

Superior Electrical Insulation – Its low dielectric constant minimizes signal loss, enhancing performance in high-frequency circuits.

-

Exceptional Mechanical Strength – High tensile strength and dimensional stability ensure durability in demanding industrial environments.

Diverse Industrial Applications

The versatility of 7628 fiberglass fabric has led to its widespread adoption across multiple high-tech sectors:

-

Electronics & PCB Manufacturing

-

Serves as the primary reinforcement material in FR-4 epoxy laminates, which are essential for producing high-performance PCBs.

-

Critical for 5G infrastructure, IoT devices, and advanced computing systems, where signal integrity and thermal management are paramount.

-

-

Aerospace & Defense

-

Used in radar domes, satellite components, and aircraft structural parts due to its lightweight yet robust nature.

-

Resists harsh environmental conditions, including thermal cycling, radiation, and moisture exposure, ensuring long-term reliability.

-

-

Automotive & Electric Vehicles (EVs)

-

Enhances the durability of EV battery housings, power modules, and onboard electronics by providing excellent insulation and impact resistance.

-

Contributes to weight reduction in vehicles while maintaining structural integrity, a key factor in improving energy efficiency.

-

Market Expansion and Future Outlook

The global market for 7628 electronic fiberglass fabric is projected to grow at a compound annual growth rate (CAGR) of 6.5% from 2024 to 2030, driven by increasing demand in 5G technology, electric vehicles, and renewable energy systems. Manufacturers are also focusing on sustainable production methods, such as recycling glass fibers, to align with environmental regulations without compromising performance.

Conclusion

As industries continue to push the boundaries of innovation, 7628 electronic fiberglass fabric remains a cornerstone material in high-performance applications. Its unique combination of electrical, thermal, and mechanical properties ensures its continued relevance in next-generation technologies.

For engineers and manufacturers seeking reliable, high-performance solutions, 7628 fiberglass fabric represents both the present and future of advanced material science.

7628 Fiberglass Fabric,Electronic Grade Fiberglass,PCB Substrate, High-Temperature Insulation,Composite Reinforcement

Related news

7628 Electronic Fiberglass Fabric: The Backbone of Modern High-Performance Electronics

2025-07-10

Fiberglass Self-Adhesive Tape: A Multifunctional Marvel for Sealing and Reinforcement

2025-07-08