Welcome To Hebei Xiongan Hengyun Technology Co., Ltd.

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Self-Adhesive Fiberglass Tape: Revolutionizing Seam Strength and Speed in Modern Construction

2025-06-25

Self-Adhesive Fiberglass Tape: Revolutionizing Seam Strength and Speed in Modern Construction

For decades, achieving seamless, durable, and crack-resistant joints in drywall, plastering, and various repair applications relied on a messy, time-consuming ritual: applying paper or mesh tape with wet joint compound (mud). While effective, this process demanded skill, patience, and created significant cleanup. Enter a game-changing innovation: Self-Adhesive Fiberglass Tape (SAFT). This unassuming roll of technology is rapidly transforming job sites, offering unparalleled speed, ease of use, and exceptional performance, making it a cornerstone of modern, efficient construction and repair.

I. The Core Advantages

-

Unmatched Speed and Efficiency: This is the biggest game-changer. Eliminating the step of applying "bedding" mud before taping drastically cuts application time. Workers simply cut the tape to length, peel the liner, press it firmly onto the joint, and move on. Corners (both inside and outside) become significantly faster and easier to handle. Projects progress faster, labor costs are reduced, and deadlines are met more easily.

-

Simplified Process & Reduced Mess: No more pre-coating joints with mud means less mess on tools, floors, and the worker. Cleanup is faster and easier. The process is more forgiving for less experienced users, as the tape stays put immediately.

-

Superior Bonding and Crack Resistance: The PSA creates an instant, continuous bond along the entire length of the joint, directly to the substrate. This immediate adhesion, combined with the high tensile strength and stability of the fiberglass scrim, creates an incredibly robust reinforcement system. Joints reinforced with SAFT are significantly less prone to cracking over time due to building settlement, temperature fluctuations, or vibration compared to traditional paper tape. The fiberglass's dimensional stability prevents the tape itself from causing stress cracks.

-

Enhanced Strength and Durability: Fiberglass scrim boasts much higher tensile strength than paper tape. It resists tearing during application and provides superior long-term reinforcement. It's also resistant to moisture, mold, and mildew, contributing to healthier indoor environments and long-lasting repairs.

-

Fire Resistance: Fiberglass is non-combustible (typically meeting ASTM E84 Class A standards), making SAFT a safer choice, particularly in areas requiring enhanced fire ratings, compared to flammable paper tape.

-

Versatility: While primarily associated with drywall, SAFT excels in numerous applications

II. The Application Process

-

Prepare the Joint: Ensure the joint between drywall panels (or the crack/repair area) is clean, dry, and free of dust, loose debris, or old compound. A slightly recessed joint (like a standard drywall butt joint) is ideal.

-

Cut & Peel: Cut a length of SAFT slightly longer than the joint. Peel away the release liner, exposing the adhesive.

-

Position & Press: Carefully position the tape over the joint, adhesive side down. Starting from the center, use your fingers or a drywall knife to press the tape firmly and smoothly onto the surface, working outwards to eliminate air bubbles or wrinkles. Ensure full contact, especially along the edges.

-

Embed in Compound: Apply a layer of joint compound (mud) over the tape using a drywall knife. Press firmly to force the mud through the open mesh of the fiberglass, embedding the tape completely. Smooth the mud, feathering the edges.

-

Finish as Usual: Allow the first coat to dry, apply subsequent coats as needed, sand, and finish.

III. Addressing Common Questions & Best Practices

- Can you use SAFT on corners? Absolutely! It's ideal for corners. Pre-creased SAFT is available specifically for inside corners, making application even faster and more precise. Apply directly to the corner and embed with mud.

- Does it need mud underneath? No. The entire point of the self-adhesive is to eliminate this step. Applying mud underneath can actually hinder the adhesive bond and create air pockets.

- Is it as strong as paper tape with mud? When properly embedded in joint compound, high-quality SAFT provides superior crack resistance due to its strength and stability. The initial bond from the PSA provides immediate stability that paper lacks until the mud dries.

- Can it bubble? Bubbling is rare with SAFT if applied correctly (pressed firmly from the center outwards). Its dimensional stability prevents the tape itself from expanding and bubbling like paper can. Any bubbles are usually trapped air from improper embedding in mud, not the tape lifting.

- Choosing Quality: Look for tapes with a strong, consistent adhesive, high-quality fiberglass scrim with good tensile strength, and a cleanly releasing liner. Reputable brands matter for performance.

IV. The Future of Joint Reinforcement

Self-Adhesive Fiberglass Tape is not just a convenient alternative; it represents a significant technological advancement in building materials. Its adoption continues to surge across professional contracting and the DIY market due to its undeniable advantages in speed, ease, performance, and reliability. As formulations potentially evolve for even stronger bonds or specialized substrates (like extreme temperatures), its role will only solidify.

Self-Adhesive Fiberglass Tape,Crack-Resistant Drywall Tape,Pressure-Sensitive Reinforcement Tape,Time-Saving Construction Tape,Mold-Resistant Joint Tape

Related news

Self-Adhesive Fiberglass Tape: Revolutionizing Seam Strength and Speed in Modern Construction

2025-06-25

Fiberglass Yarn: Revolutionizing High-Performance Textiles

2025-06-20

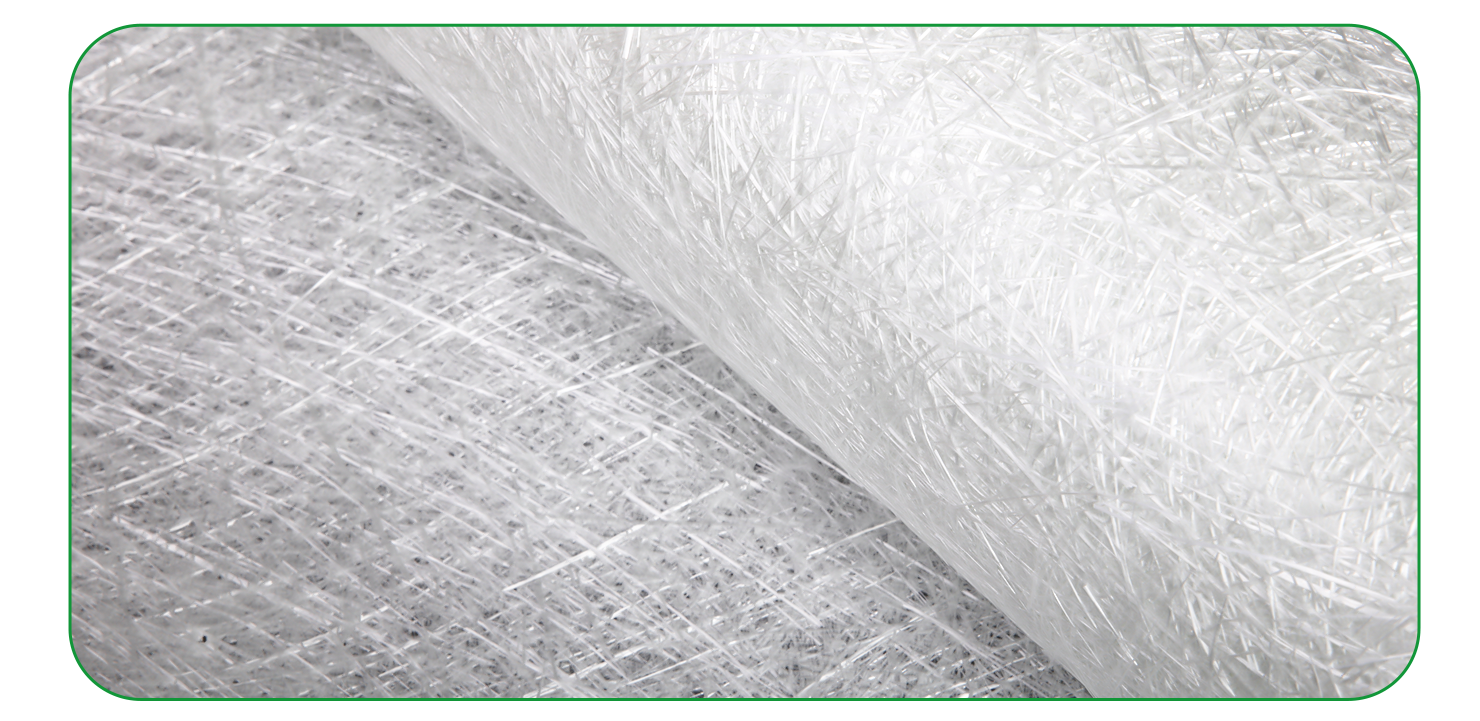

Fiberglass Chopped Strand Mat: The Versatile Foundation of Composite Manufacturing

2025-06-18