Welcome To Hebei Xiongan Hengyun Technology Co., Ltd.

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Fiberglass Yarn: Revolutionizing High-Performance Textiles

2025-06-20

Introduction

Fiberglass yarn, made from ultra-thin glass fibers, has become a cornerstone in modern industrial and commercial applications. Its unique combination of strength, flexibility, and thermal stability makes it ideal for demanding environments.

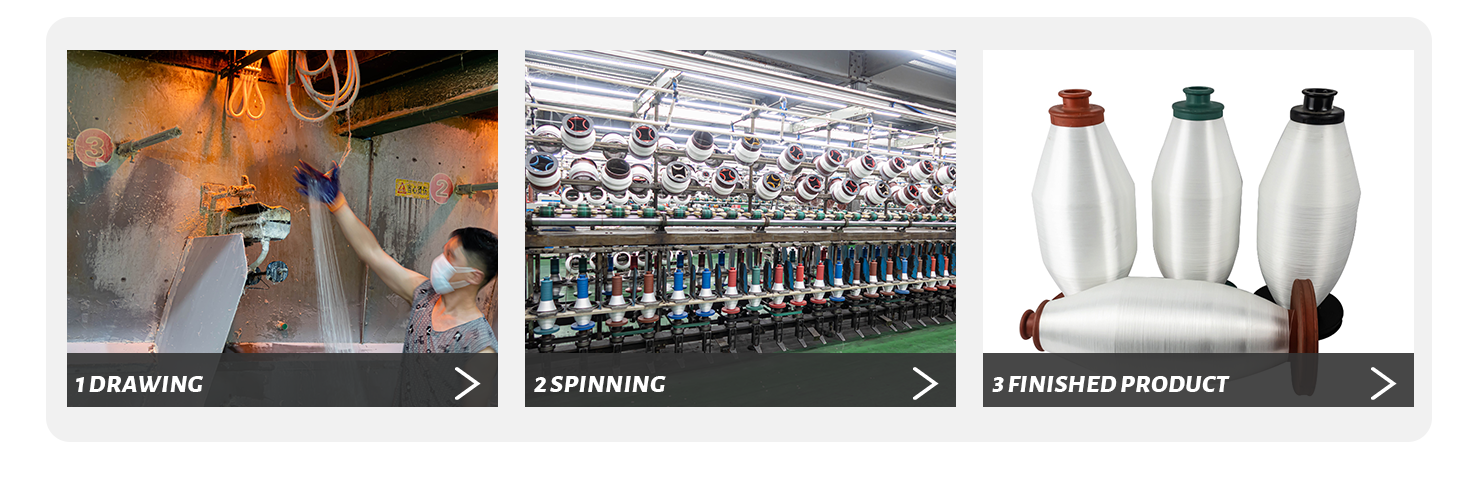

Manufacturing Process

Fiberglass yarn is produced by melting silica sand and other raw materials at high temperatures, then extruding them into fine filaments. These filaments are coated with a sizing agent for enhanced adhesion and spun into yarn. The resulting product is lightweight yet incredibly strong.

Key Advantages

-

High Strength-to-Weight Ratio – Stronger than steel yet significantly lighter.

-

Thermal & Chemical Resistance – Withstands extreme temperatures and corrosive environments.

-

Electrical Insulation – Non-conductive, making it ideal for electronics.

-

Flexibility & Weavability – Can be woven into fabrics or used as reinforcement in composites.

Applications

-

Aerospace & Automotive: Used in lightweight composites for aircraft and vehicle parts.

-

Construction: Reinforces concrete and insulation materials.

-

Electronics: Serves as a protective layer in circuit boards.

-

Protective Gear: Fire-resistant clothing and safety equipment.

Future Trends

With advancements in nanotechnology, fiberglass yarn is expected to play a bigger role in smart textiles and eco-friendly materials. Researchers are also exploring its use in renewable energy systems like wind turbine blades.

Conclusion

Fiberglass yarn continues to transform industries with its unmatched properties. As technology evolves, its applications will expand, reinforcing its status as a critical material in high-performance textiles.

Fiberglass yarn,high-performance textiles,lightweight materials,thermal insulation,corrosion resistance, industrial applications

Related news

Fiberglass Yarn: Revolutionizing High-Performance Textiles

2025-06-20

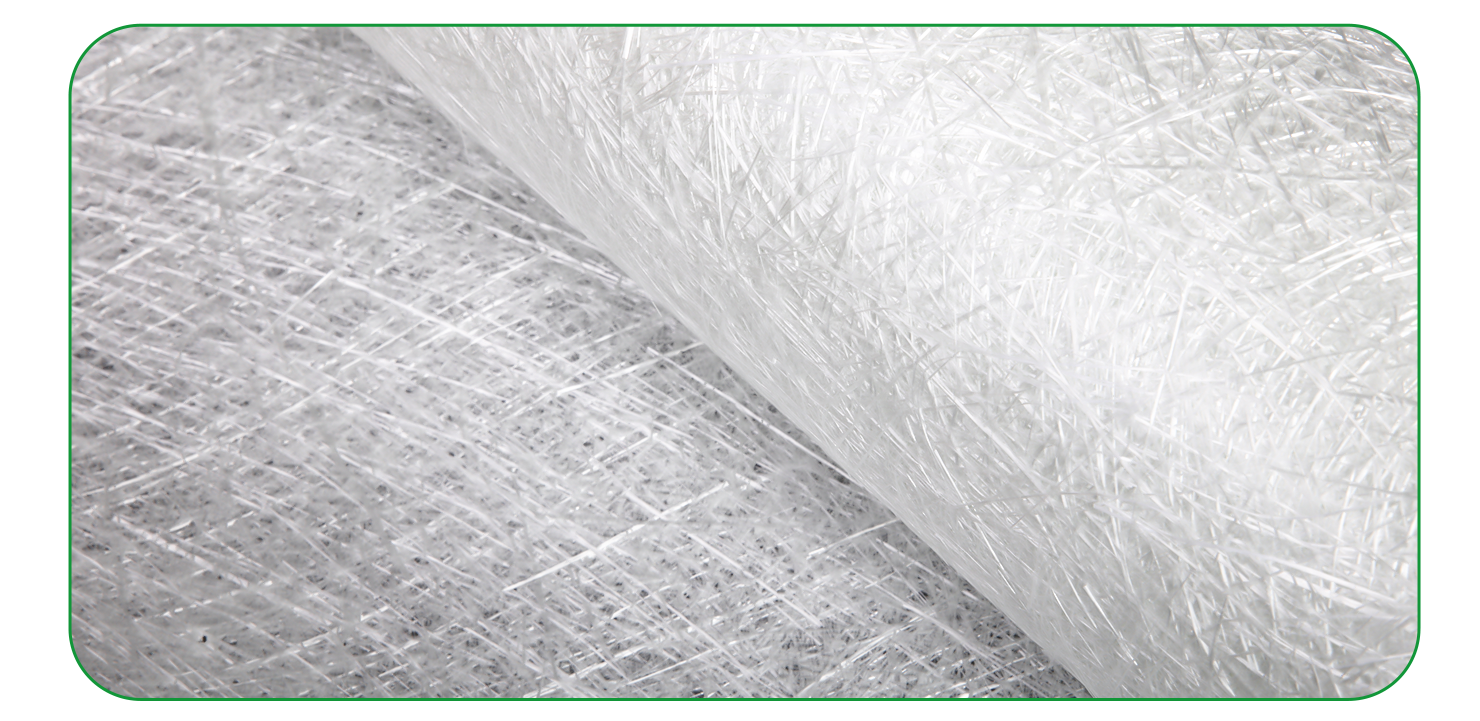

Fiberglass Chopped Strand Mat: The Versatile Foundation of Composite Manufacturing

2025-06-18

Fiberglass Fine Yarn: The Invisible Strength Behind Modern Materials

2025-06-17