Welcome To Hebei Xiongan Hengyun Technology Co., Ltd.

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

The Fabric of Strength: Fiberglass Woven Roving Powers the Composite Revolution

2025-12-03

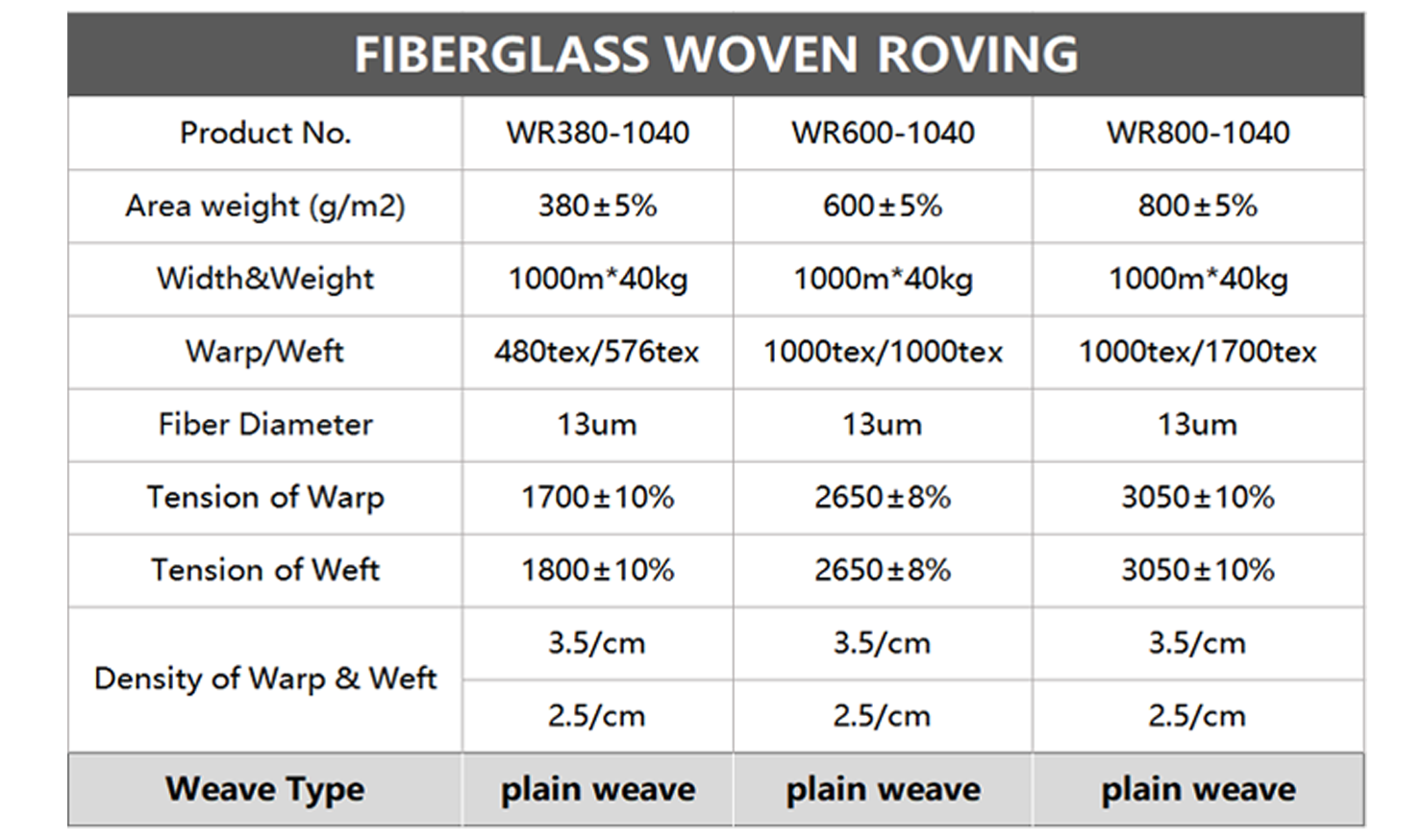

In the world of advanced composites, where strength meets lightness, one material has consistently proven itself as a foundational powerhouse: Fiberglass Woven Rving. Far more than just a fabric, this robust grid of interwoven continuous glass fiber strands is the muscle behind countless applications that demand resilience, durability, and cost-effective performance. As industries push for lighter, stronger, and more sustainable solutions, woven roving is experiencing a renaissance, cementing its role as an indispensable material for engineers and fabricators globally.

Engineered for Performance: The Anatomy of a Powerhouse

Fiberglass woven roving is manufactured by weaving continuous filaments into a coarse, drapeable fabric with a distinctive basket-weave pattern. This construction is key to its success. The continuous fibers provide exceptional tensile strength, while the open weave allows for rapid resin wet-out and excellent laminate build-up. Unlike finer fabrics, woven roving is designed to add substantial thickness and structural integrity to a composite part in fewer layers, making it exceptionally efficient for hand lay-up, spray-up, and resin infusion processes. Its primary virtues are undisputed: high strength-to-weight ratio, remarkable impact resistance, outstanding dimensional stability, and inherent corrosion resistance.

Charting the Waters: The Bedrock of Marine Excellence

Perhaps no industry is more synonymous with fiberglass woven roving than boatbuilding. It forms the rugged backbone of hulls, decks, and structural components for vessels ranging from nimble fishing boats to luxurious yachts. Its ability to create thick, impact-resistant laminates is crucial for withstanding the relentless forces of the sea—from pounding waves to accidental groundings. The material’s durability ensures longevity in harsh saltwater environments, resisting osmosis and fatigue where metals would corrode and wood would rot. For marine engineers, woven roving is not just a material; it is a trusted partner in ensuring safety and performance on the water.

Driving the Future: Lightweighting the Transportation Sector

Beyond the waves, woven roving is accelerating innovation on land. In the transportation sector, the push for fuel efficiency and reduced emissions has made weight reduction a paramount concern. Composite panels reinforced with woven roving are revolutionizing truck and trailer bodies, offering a lightweight yet incredibly durable alternative to traditional materials like steel or aluminum. This translates directly into higher payload capacities and lower fuel consumption. Similarly, the material is essential in manufacturing recreational vehicles, cargo containers, and even components for mass transit, where its strength and damage tolerance are critical for long service life under demanding conditions.

Building a Resilient World: Infrastructure and Industrial Applications

The construction and industrial sectors are increasingly turning to composites for solutions that traditional materials cannot provide. Here, fiberglass woven roving shines in the fabrication of large-scale structural shapes, protective covers, and heavy-duty storage tanks for water and chemicals. Its use in architectural panels, balcony enclosures, and bridge components offers a blend of aesthetic freedom and structural soundness that resists weathering and maintenance headaches. In energy, it is used in wind turbine blade components and protective housings, while in water management, it is the material of choice for robust, corrosion-resistant piping and scrubbers in treatment facilities.

A Sustainable and Evolving Material for a Demanding Future

The future of fiberglass woven roving is aligned with the broader trends of sustainability and technological advancement. Manufacturers are continually improving the compatibility of roving with bio-based and low-VOC resins, enhancing the eco-profile of the final composite. Innovations in weaving technology allow for tailored weight, drape, and strength characteristics to meet specific engineering requirements. Furthermore, its role in repairing and reinforcing aging infrastructure—from bridges to pipes—highlights its value in circular economy principles, extending the life of existing assets.

In conclusion, Fiberglass Woven Roving stands as a testament to timeless engineering principles meeting modern challenges. Its straightforward, no-nonsense strength, combined with unparalleled versatility, makes it a cornerstone of the composites industry. As we navigate toward a future that demands smarter, lighter, and more durable solutions from our materials, this rugged fabric of glass will undoubtedly continue to be woven into the very fabric of industrial progress, proving that true strength often lies in a well-engineered foundation.

Fiberglass Woven Roving,Composite Reinforcement,Boatbuilding,Structural Strength,Resin Infusion,Impact Resistance,Industrial Composites

Related news

Fiberglass Corner Mesh: The Architectural Guardian of Perfect Angles

2025-12-15

Building Stronger Corners: Fiberglass Mesh Ushers in a New Era of Precision and Durability

2025-12-11

The Fabric of Strength: Fiberglass Woven Roving Powers the Composite Revolution

2025-12-03