Welcome To Hebei Xiongan Hengyun Technology Co., Ltd.

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Fiberglass Corner Mesh: The Architectural Guardian of Perfect Angles

2025-12-15

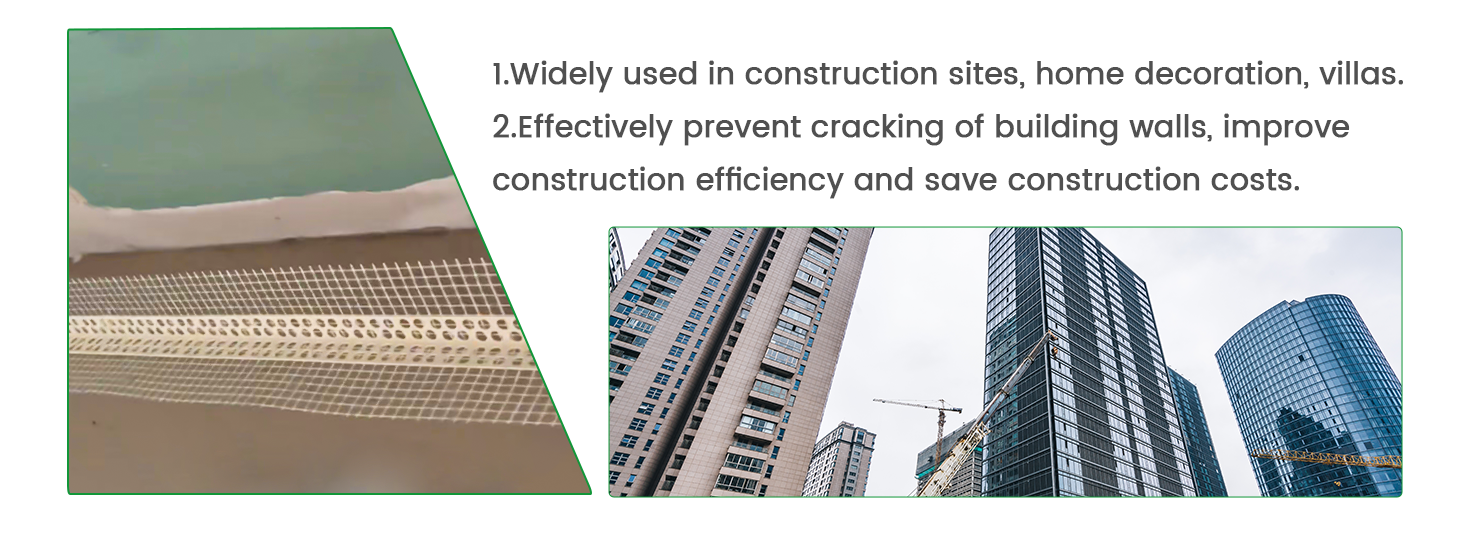

In the world of contemporary construction, where precision meets permanence, a specialized material has emerged as a quiet yet revolutionary force in architectural integrity: fiberglass corner mesh. Far more than a simple accessory, this engineered solution addresses one of the most persistent challenges in building—protecting vulnerable corners from damage, cracks, and wear. As construction standards rise and client expectations demand flawless finishes, this unassuming product is proving indispensable for projects that value longevity as much as aesthetics, seamlessly blending robust protection with seamless application.

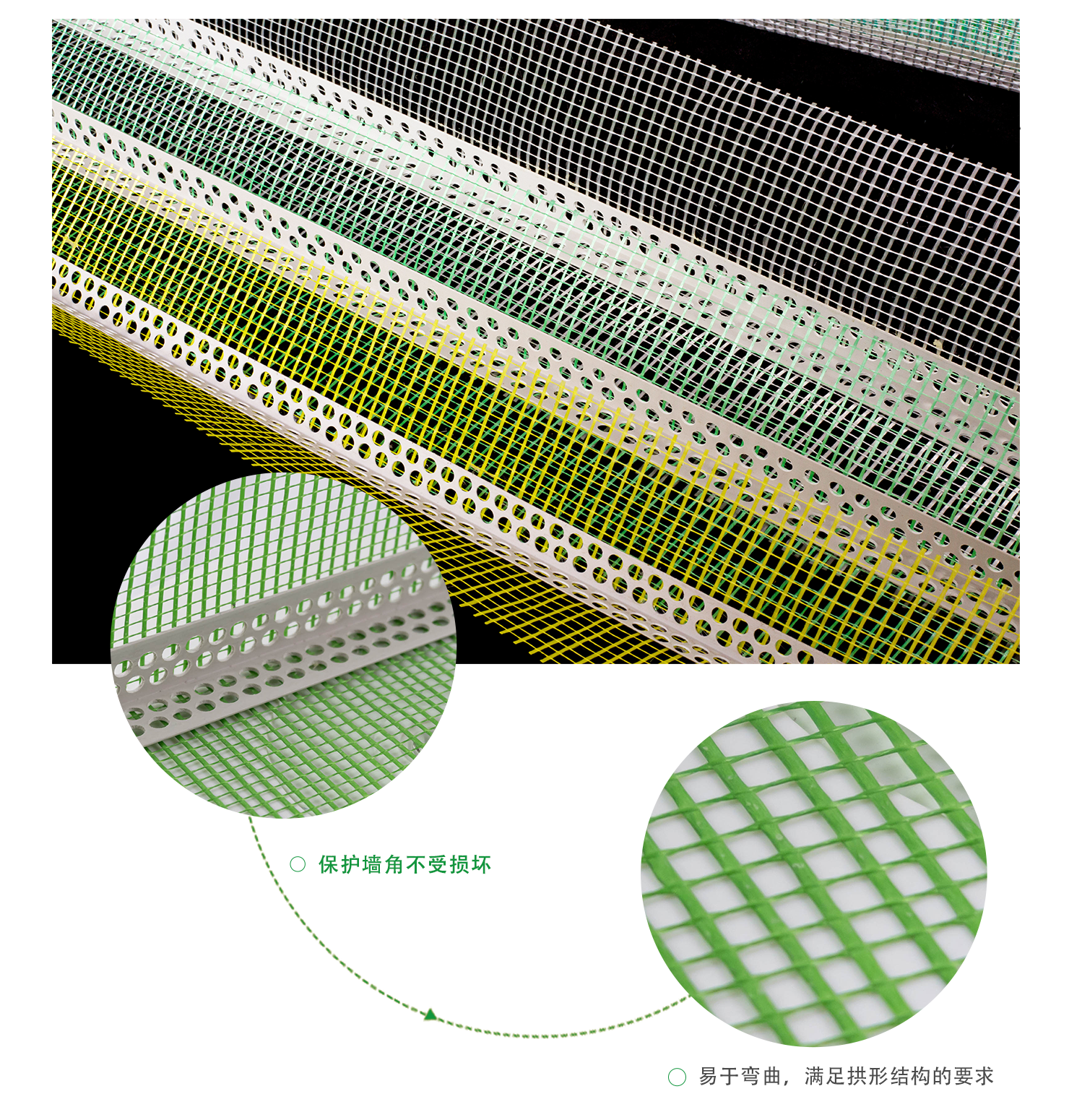

The critical role of corner protection stems from a fundamental structural reality: corners are inherently susceptible points. They concentrate stress, bear the brunt of incidental impacts, and are often the first areas to show cracks due to natural building movement or material shrinkage. Traditional methods of corner reinforcement frequently fell short, leading to compromised aesthetics and potential structural concerns over time. Fiberglass corner mesh, with its pre-formed right-angle design and integrated reinforcing spine, transforms this weak link into a fortified asset. By distributing stress across a broader area and creating a flexible yet durable bond with plaster, stucco, or drywall compounds, it effectively prevents the formation of cracks while maintaining crisp, clean lines that define professional craftsmanship.

The application versatility of fiberglass corner mesh is a key driver of its widespread adoption. Its primary use in Exterior Insulation and Finishing Systems (EIFS) ensures that building exteriors can withstand environmental stresses while maintaining energy-efficient envelopes. Equally vital is its role in interior systems, where it reinforces drywall corners in high-traffic commercial spaces and residential settings alike, preventing damage from everyday use. The mesh also plays a crucial role in tile and waterproofing applications, securing moisture barriers in bathrooms, kitchens, and wet areas. This cross-functional utility makes it a universal solution for builders and contractors seeking consistency across diverse project requirements.

Installation efficiency represents another significant advantage. The pre-formed design eliminates the guesswork from achieving perfect 90-degree angles, reducing labor time and material waste compared to traditional corner bead methods. When embedded in a base coat or adhesive, the mesh wings integrate completely with wall reinforcement systems, creating a monolithic bond that moves uniformly with the structure. This seamless integration is particularly valuable in regions prone to seismic activity or temperature extremes, where flexibility and resilience are paramount. The result is not only a stronger corner but also a smoother surface that requires less finishing compound and minimizes sanding effort.

From a sustainability perspective, fiberglass corner mesh contributes meaningfully to green building practices. By preventing cracks that can compromise thermal and moisture barriers, it enhances a structure's long-term energy performance. The extended lifespan it provides reduces the frequency of repairs and renovations, thereby conserving resources and minimizing construction waste. Modern formulations often feature alkali-resistant coatings and compatibility with low-VOC compounds, supporting healthier indoor air quality and aligning with increasingly stringent environmental standards for both residential and commercial projects.

The economic implications extend across the project lifecycle. While representing a minor initial investment, the inclusion of corner mesh substantially reduces callbacks for crack repairs—a frequent and costly issue in construction warranties. For building owners, this translates to lower maintenance costs and preserved property value. For architects and specifiers, it offers assurance that their designs will maintain their intended appearance over time, protecting both aesthetic vision and professional reputation. The material's resistance to corrosion, mold, and shrinking ensures performance that lasts as long as the structure itself.

Innovation continues to propel this category forward. Manufacturers are developing enhanced versions with improved adhesion properties, greater flexibility for curved surfaces, and even integrated alignment features for simplified installation. Some advanced products combine corner reinforcement with drainage or insulation layers, creating multifunctional assemblies that address several building envelope requirements simultaneously. As digital fabrication and Building Information Modeling (BIM) become more prevalent, the specification of such precision components will likely become even more integrated into automated design and construction workflows.

Industry response has been unequivocally positive, with building codes and professional guidelines increasingly recognizing systematic corner reinforcement as a best practice rather than an optional upgrade. Training programs and technical certifications now routinely include proper corner mesh installation techniques, acknowledging its role in quality assurance. This institutional acceptance reinforces its position not as a temporary trend but as a fundamental component of durable construction.

In conclusion, fiberglass corner mesh exemplifies how targeted material innovation can solve age-old building challenges while supporting broader goals of durability, efficiency, and design fidelity. It stands as a testament to the construction industry's evolving commitment to building smarter—where every detail, no matter how seemingly small, contributes to the whole structure's integrity and longevity. As the demand for resilient and sustainable buildings grows, this guardian of perfect angles will undoubtedly remain a cornerstone of quality construction, ensuring that today's built environments meet tomorrow's challenges with unwavering strength.

Related news

Fiberglass Corner Mesh: The Architectural Guardian of Perfect Angles

2025-12-15

Building Stronger Corners: Fiberglass Mesh Ushers in a New Era of Precision and Durability

2025-12-11

The Fabric of Strength: Fiberglass Woven Roving Powers the Composite Revolution

2025-12-03