Welcome To Hebei Xiongan Hengyun Technology Co., Ltd.

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Premium Fiberglass Chopped Strand Mat for Composite Manufacturing

2025-06-03

Premium Fiberglass Chopped Strand Mat for Composite Manufacturing

I. Overview

Glass fiber chopped strand mat (CSM) is a nonwoven reinforcing material made by randomly distributing chopped glass fibers and fixing them with binders such as powder or emulsion. It is widely used in the manufacturing of composite materials, such as fiberglass reinforced plastic (FRP), ships, automobiles, wind turbine blades, chemical storage tanks and other fields, and is highly favored for its low cost, easy operation and excellent mechanical properties.

II. Manufacturing Process

The production of glass fiber chopped strand mat mainly includes the following steps:

1. Fiber preparation:

The raw materials are usually E-glass (alkali-free glass fiber) or C-glass (acid-resistant glass fiber), and continuous fibers are formed after melting and drawing.

The fibers are short-cut to a length of 25mm to 50mm to optimize the subsequent dispersion and reinforcement effect.

2. Felting process:

Wet forming: Chopped fibers are suspended in water, and through the papermaking process, they form felt sheets, which are then dried and solidified with binders.

Dry molding: Chopped fibers are dispersed by air flow, then sprayed with a binder (polyester powder or emulsion), and finally formed through hot pressing and curing.

3. Adhesive type:

Powder binder: High-temperature resistant, suitable for high-temperature molding processes such as pultrusion and compression molding.

Emulsion binder: Good solubility, suitable for room-temperature curing processes such as hand lay-up and vacuum infusion.

III. Main Characteristics

Glass fiber chopped strand mat has the following core properties:

1. Mechanical properties:

Due to the random distribution of fibers, CSM is isotropic in the plane and is suitable for multi-directional force-bearing structures.

It has a relatively high tensile strength, but is lower than that of continuous fiber fabrics (such as checkered fabric).

2. Resin wettability:

The loose arrangement of fibers enables resins (such as unsaturated polyester, epoxy, and vinyl ester) to penetrate quickly, reduce bubbles, and enhance interlayer adhesion.

3. Molding adaptability:

It is applicable to various processes such as Hand layup, Spray Molding, Compression Molding and Vacuum Infusion.

4. Economy:

Compared with woven fabric or unidirectional fabric, CSM has a lower price and is suitable for large-scale production.

IV. Application Fields

Glass fiber chopped strand mat is widely used in the following industries:

1. Shipbuilding

It is used for reinforcing the hull, deck and bulkhead to enhance impact resistance and corrosion resistance.

2. Automotive Industry

It is used for lightweight components such as body panels, bumpers, and battery boxes.

3. Wind power energy:

It is used for layering at the root of fan blades and the casing to enhance fatigue resistance.

4. Chemical anti-corrosion:

It is used for making acid and alkali resistant equipment such as storage tanks, pipelines and scrubbers.

4. Building materials:

It is used for fiberglass reinforced plastic tiles, light-transmitting panels, cooling towers and other building composite materials.

Resin compatibility,Corrosion resistance,E-glass fiber mat,FRP composites

Related news

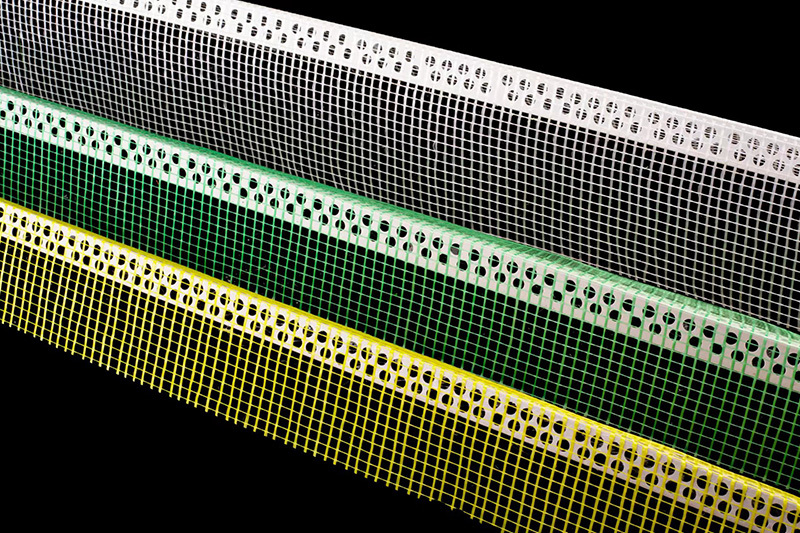

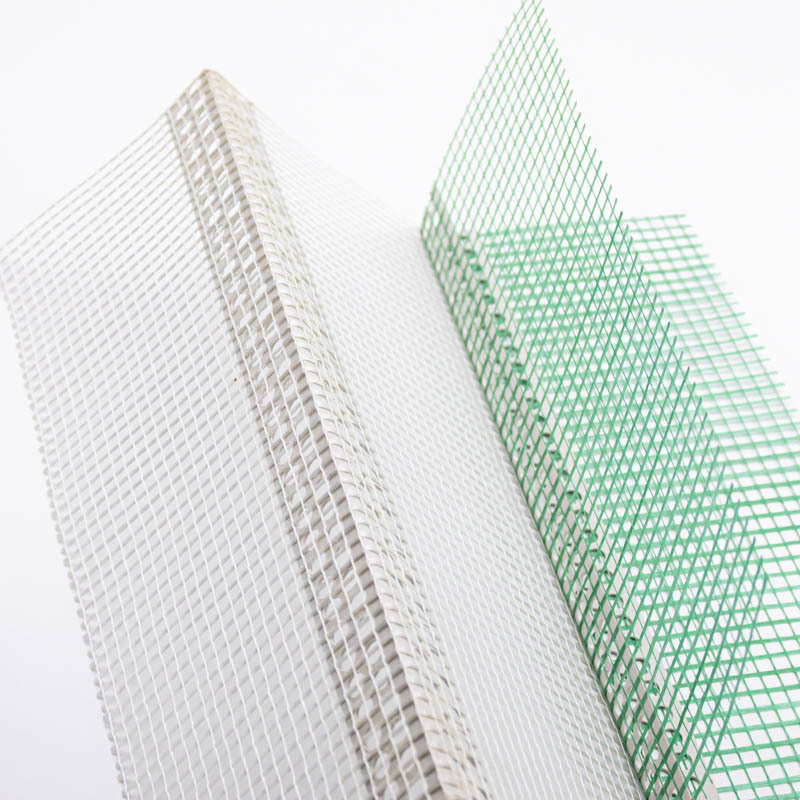

Fiberglass Corner Mesh: Innovation in the Construction Material Industry

2025-06-04

Alkali-Resistant Fiberglass Corner Mesh for Interior/Exterior Corners

2025-06-04

Premium Fiberglass Chopped Strand Mat for Composite Manufacturing

2025-06-03