Welcome To Hebei Xiongan Hengyun Technology Co., Ltd.

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Fiberglass Corner Mesh: Innovation in the Construction Material Industry

2025-06-04

Introduction

The construction industry continuously seeks materials that enhance structural performance while meeting sustainability demands. Fiberglass Corner Mesh has emerged as a pivotal composite material designed to offer superior corner reinforcement and pristine finish across multiple construction applications, addressing common issues like cracking in plaster and vulnerable corners.

This article analyzes Fiberglass Corner Mesh, exploring its material composition, physical properties, technical specifications, and technological innovations. We'll also examine its diverse applications, environmental value, and comparative advantages over traditional materials.

Product Features of Fiberglass Corner Mesh

Material Composition

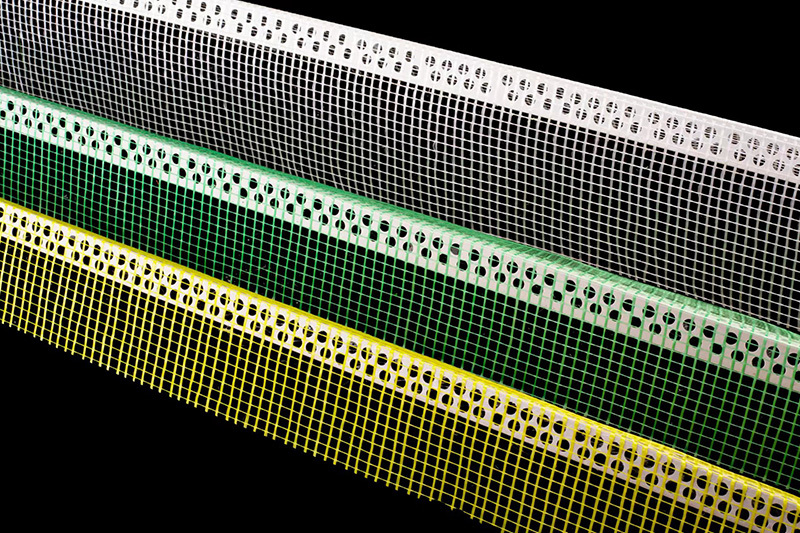

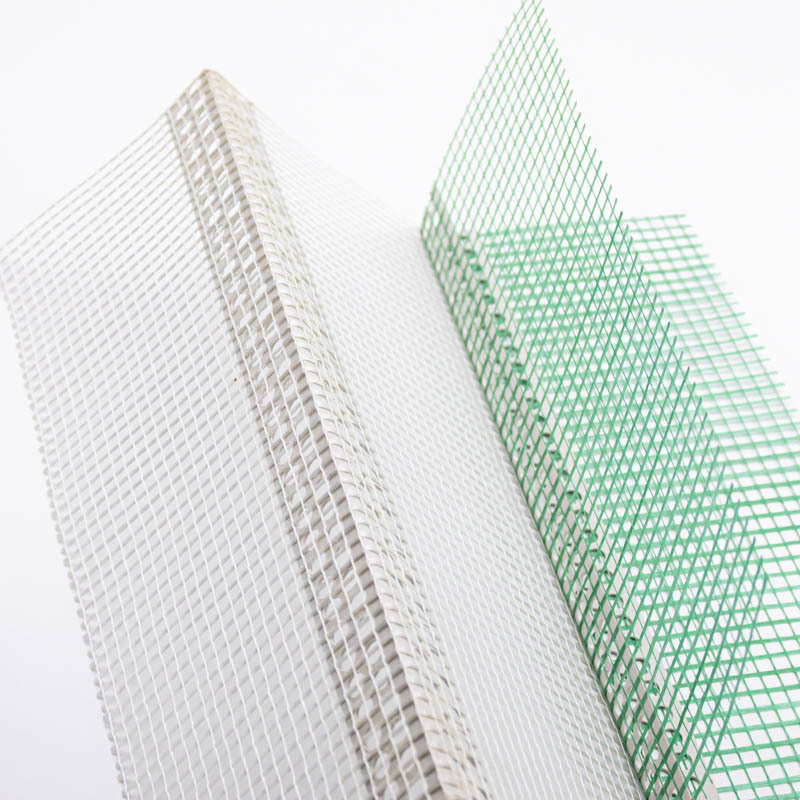

Glass Fiber Angle Bead Mesh combines a rigid profile with flexible reinforcing mesh wings:

- Angle Bead Profile: Typically manufactured from high-quality PVC (FiberglassScreenMesh.com), aluminum, stainless steel, or galvanized steel (ABO Building Materials). Profiles often feature perforations for enhanced mechanical keying with plaster systems.

- Reinforcing Mesh: Alkali-resistant (AR) fiberglass mesh wings provide tensile strength and crack resistance. The mesh is typically woven from E-glass or C-glass fiber yarns with specialized coatings to withstand alkaline environments (FiberglassMeshMachine.com).

- Bonding: The mesh is permanently bonded to the bead profile through heat sealing (Dakota Group) or specialized adhesives.

Physical and Chemical Properties

Key properties include:

- High Tensile Strength: Ranges from 1000 N/50mm to over 2500 N/50mm (FiberglassWireMesh.com).

- Superior Alkali Resistance: Maintains >70-80% tensile strength after prolonged immersion in alkaline solutions.

- Impact Resistance: The composite structure protects corners from mechanical damage (EJOT).

- Corrosion Resistance: PVC and fiberglass are inherently resistant to rust and corrosion.

- Dimensional Stability: Low shrinkage and expansion rates across temperature and humidity fluctuations.

- Lightweight: Easier to transport, handle, and install compared to metal alternatives (ABO Building Materials).

Technical Specifications

- Angle Bead Profile: Typically 90°, with some universal types accommodating angles from 90° to 179° (Mat-Plasty). Common profile dimensions: 20x20mm, 25x25mm, 30x30mm.

- Mesh Wings: Width ranges from 70x70mm to 100x150mm (Walcoom PDF). Mesh openings typically 4x4mm or 5x5mm.

- Product Length: Available in standard lengths (2.0-3.0m) or rolls (25-50m) for flexible types.

Key Product Features Summary

- Composite Material: PVC/Aluminum profile with alkali-resistant fiberglass mesh wings.

- High Performance: Excellent tensile strength, impact and corrosion resistance, dimensional stability.

- Versatile Specifications: Available in various sizes, lengths, and for different angles.

- Enhanced Adhesion: Perforated profiles and mesh texture ensure strong bonding with plaster/render.

Technological Innovations

Key innovations include:

- Integrated Composite Design: The synergistic combination of rigid profiles with flexible, high-strength mesh creates a product that's easy to install while effectively reinforcing vulnerable corners (Dakota Group).

- Advanced Alkali-Resistant Coatings: Sophisticated polymer coatings protect glass fibers in alkaline environments, ensuring long-term durability (FiberglassMeshMachine.com).

- Perforated Profile Design: Strategic perforations allow plaster to penetrate and create a monolithic bond between the bead, render, and substrate (FiberglassScreenMesh.com).

- Flexible/Universal Angle Designs: Multi-angle corner beads accommodate angles from 90° to 179°, providing greater design flexibility (Mat-Plasty).

Application Areas

Primary Construction Applications

- Exterior Insulation and Finish Systems (EIFS/ETICS): Reinforces external corners, window reveals, and architectural details, preventing cracks and ensuring straight edges (ABO Building Materials).

- Internal Plastering and Drywall Finishing: Creates durable corners in gypsum plaster, lime plaster, or drywall systems (FiberglassScreenMesh.com).

- Arches and Curved Features: Flexible variants adapt to curved walls and architectural features.

- Window and Door Jambs/Reveals: Provides clean edges around openings, helping prevent stress cracks (Mat-Plasty).

Suitable Building Types

Applications include:

- New Construction: Residential, commercial, institutional, and industrial buildings.

- Renovation Projects: Upgrading existing buildings, repairing damaged corners, and improving finishes.

- Diverse Climate Conditions: Suitable for varied geographical regions due to moisture and temperature resistance.

Environmental Value

Eco-friendly Aspects

- Raw Materials: Some manufacturers incorporate recycled content in PVC profiles, though this varies by product (Sto Sustainability Data Sheet). Low-VOC coatings reduce harmful emissions.

- Production Processes: Progressive adoption of energy-efficient techniques and environmental management standards like ISO 14001.

Contribution to Building Sustainability

- Enhanced Durability: Extends the life of plaster and EIFS systems, reducing repair frequency, material consumption, and waste.

- Improved Building Envelope Integrity: Well-reinforced corners maintain a continuous thermal envelope, preserving energy efficiency.

- Waste Reduction: Lightweight material reduces transport impacts and on-site cutting waste.

- Recycling Potential: Some products can be sorted and recycled at end-of-life (Sto Sustainability Data Sheet).

Fiberglass Corner Mesh ,Construction material,Corner reinforcement,Alkali-resistant fiberglass,Crack prevention,Durability,Tensile strength,Impact resistance,Corrosion resistance,PVC coating,Lightweight material

Related news

Fiberglass Corner Mesh: Innovation in the Construction Material Industry

2025-06-04

Alkali-Resistant Fiberglass Corner Mesh for Interior/Exterior Corners

2025-06-04

Premium Fiberglass Chopped Strand Mat for Composite Manufacturing

2025-06-03