Welcome To Hebei Xiongan Hengyun Technology Co., Ltd.

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

7628 Fiberglass Fabric: The High-Performance Backbone of Modern Electronics

2025-12-17

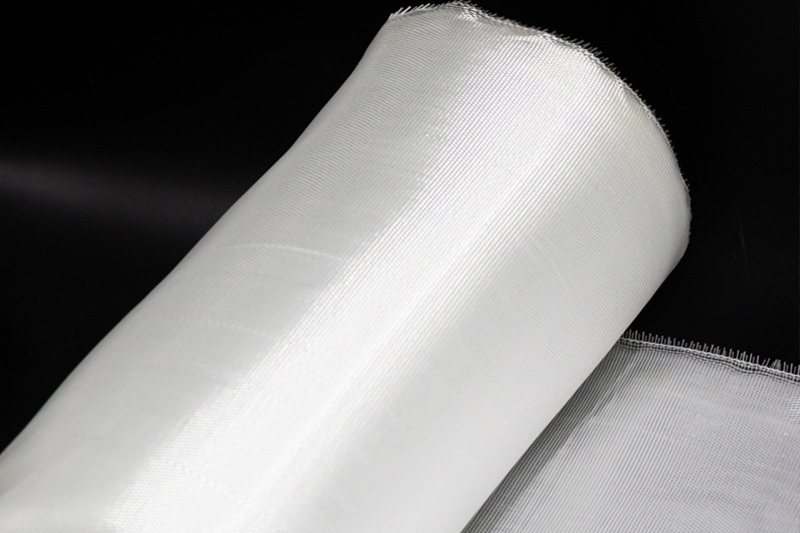

In the dynamic world of electronics manufacturing, innovation is often driven by materials that operate behind the scenes—unseen yet essential. Among these, 7628 electronic fiberglass fabric has emerged as a foundational component, powering the development of advanced printed circuit boards (PCBs) across industries. With its exceptional dimensional stability, thermal resistance, and electrical insulation properties, this specialized fabric is not just a material choice but a strategic enabler of technological progress, supporting everything from consumer gadgets to critical aerospace systems.

The Critical Role in PCB Manufacturing

At the heart of most modern electronics lies the PCB, and at the core of high-performance PCBs is 7628 fiberglass fabric. As a reinforcement material within epoxy laminates, this fabric provides the structural integrity needed for multilayered, high-density circuit designs. Its tightly woven construction—characterized by a balanced plain weave and standardized thickness—ensures minimal signal interference and superior mechanical strength. In an era where devices are becoming smaller yet more powerful, the reliability of 7628 fabric allows engineers to push the limits of miniaturization without compromising performance or durability.

Why 7628 Stands Out

The designation "7628" refers to a specific style of fiberglass fabric defined by its weave density, weight, and thickness. What sets it apart is its optimal resin compatibility, which ensures uniform saturation during the PCB lamination process. This results in flat, stable substrates that resist warping under high-temperature soldering processes—a non-negotiable requirement for surface-mount technology (SMT). Moreover, its low dielectric constant and excellent thermal properties make it ideal for high-frequency and high-speed applications, such as 5G infrastructure, automotive radar systems, and advanced computing hardware.

Driving Advancements Across Industries

The applications of 7628 fiberglass fabric stretch far beyond conventional electronics. In the automotive sector, it is integral to the PCBs used in electric vehicle (EV) battery management systems and autonomous driving modules, where reliability under extreme conditions is paramount. In aerospace and defense, the fabric’s flame-retardant qualities and compliance with stringent standards (such as UL94) ensure safety and longevity in mission-critical avionics. Meanwhile, the renewable energy industry relies on it for inverters and power converters that demand stable operation over decades. Even the Internet of Things (IoT) revolution depends on this material to produce compact, robust sensors and communication modules.

Sustainability and Manufacturing Excellence

As global industries prioritize sustainability, 7628 fiberglass fabric aligns with eco-conscious manufacturing. Its durability extends the lifespan of electronic products, reducing e-waste, while ongoing innovations in recycling-friendly epoxy systems enhance its environmental profile. Leading producers are also optimizing manufacturing processes to minimize energy consumption and waste, ensuring that the fabric supports not only technological advancement but also responsible production.

A Future Built on Reliable Foundations

Looking ahead, the demand for 7628 electronic fiberglass fabric is poised to grow alongside emerging technologies. The proliferation of artificial intelligence, edge computing, and next-generation telecommunications will require even more sophisticated PCBs—and thus, more advanced substrate materials. Continuous improvements in fiberglass treatments and hybrid weaves are already paving the way for fabrics that offer enhanced thermal conductivity and signal integrity.

In conclusion, 7628 fiberglass fabric is much more than an industrial commodity; it is a silent catalyst for electronic innovation. By delivering unmatched consistency, performance, and adaptability, it allows engineers to transform bold ideas into reliable, real-world technologies. As we venture deeper into the digital age, this unassuming material will continue to serve as the dependable backbone of the circuitry that connects, powers, and protects our modern world—proving once again that true progress often rests on foundations that are built to last.

7628 Fiberglass Fabric,PCB Substrate,Electrical Insulation,Thermal Resistance,High-Frequency Circuits,Dimensional Stability,Electronic Laminates

Related news

7628 Fiberglass Fabric: The High-Performance Backbone of Modern Electronics

2025-12-17

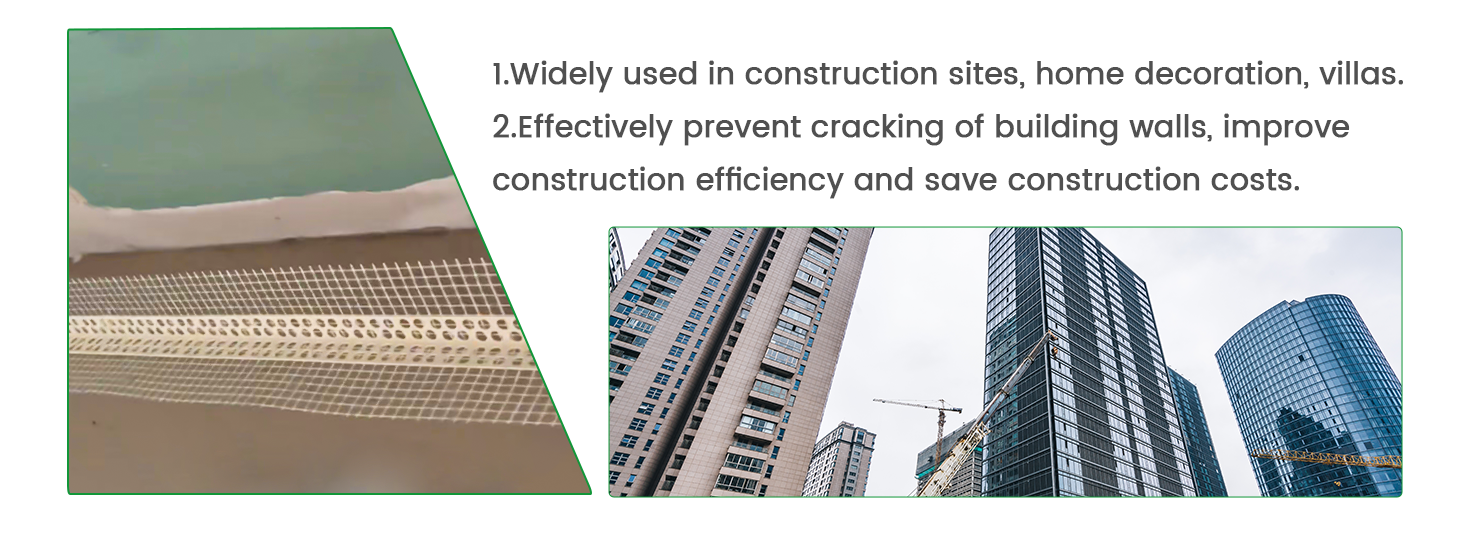

Fiberglass Corner Mesh: The Architectural Guardian of Perfect Angles

2025-12-15

Building Stronger Corners: Fiberglass Mesh Ushers in a New Era of Precision and Durability

2025-12-11