Welcome To Hebei Xiongan Hengyun Technology Co., Ltd.

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Fiberglass Mesh: The Unseen Engine of Modern Durability and Design

2025-09-25

In the ever-evolving landscape of construction and manufacturing, some of the most transformative materials are those that work behind the scenes. While steel and concrete capture the skyline, and smart glass defines modern aesthetics, there is a silent, robust workhorse that ensures their longevity and performance: fiberglass mesh. This ingenious material, a woven fabric of delicate glass filaments, is far more than a simple component; it is a foundational element driving progress toward stronger, safer, and more sustainable structures worldwide.

From its unassuming beginnings, fiberglass mesh has become an indispensable tool across a multitude of industries. Its unique combination of high tensile strength, remarkable flexibility, and resistance to environmental factors makes it a preferred solution for challenges ranging from preventing cracks in walls to reinforcing composite materials in aerospace engineering. As we look to the future of building and design, fiberglass mesh stands out as a key enabler of innovation, offering a blend of practicality and performance that is difficult to match.

The Backbone of Modern Construction

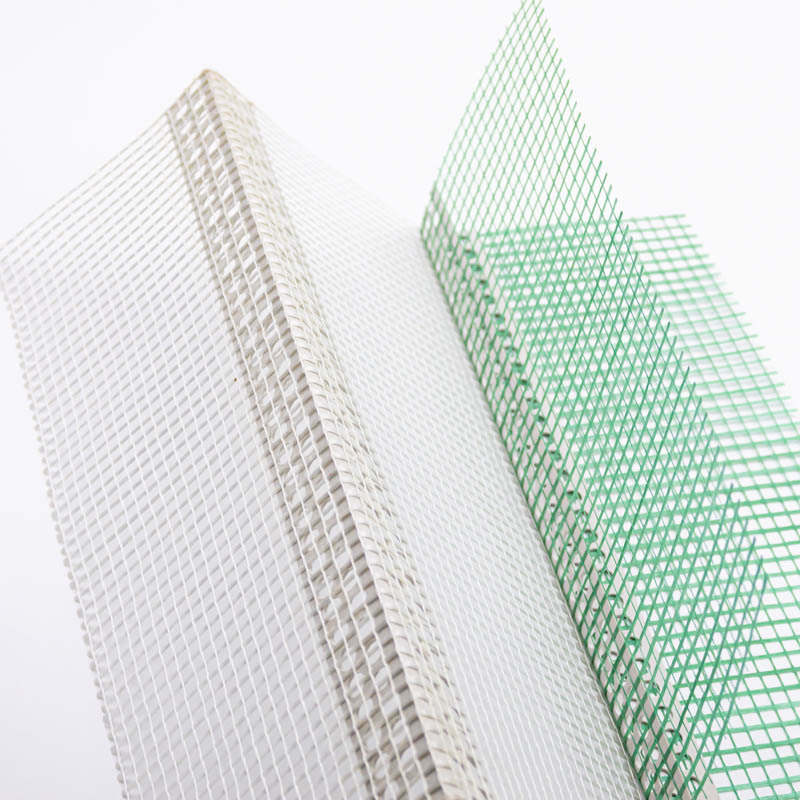

The most visible application of fiberglass mesh is in the construction industry, where it serves as the primary reinforcement for Exterior Insulation and Finish Systems (EIFS) and stucco. In these applications, the mesh is embedded into a base coat of adhesive, creating a flexible, armored layer that distributes stress and prevents cracks from propagating through the wall surface. This is crucial for managing the natural expansion and contraction of buildings due to temperature changes. Unlike older methods, fiberglass mesh moves with the structure, maintaining integrity where rigid materials would fail.

Beyond exterior walls, its role is equally vital in interior systems. It is the key component in manufacturing glass mesh tape, used to reinforce the joints between drywall panels. This prevents unsightly and structurally concerning cracks from appearing along seams, ensuring smooth, seamless walls for years to come. Furthermore, its alkali-resistant variant is specifically designed to withstand the corrosive nature of cement and plaster, making it perfect for reinforcing tile backer boards and underlayment, providing a stable, long-lasting base for tiling.

Expanding Horizons: Beyond the Building Site

The utility of fiberglass mesh extends far beyond traditional construction. Its positive impact is felt in several other critical sectors:

Infrastructure and Renovation: In restoration projects, fiberglass mesh is used to reinforce historical plasterwork, allowing for repairs that preserve the original aesthetic while adding modern durability. It is also employed in structural strengthening systems, where it is bonded to concrete, masonry, or wood structures with polymer resins to increase their load-bearing capacity and resistance to earthquakes—a technique that is often faster, lighter, and less invasive than using steel plates.

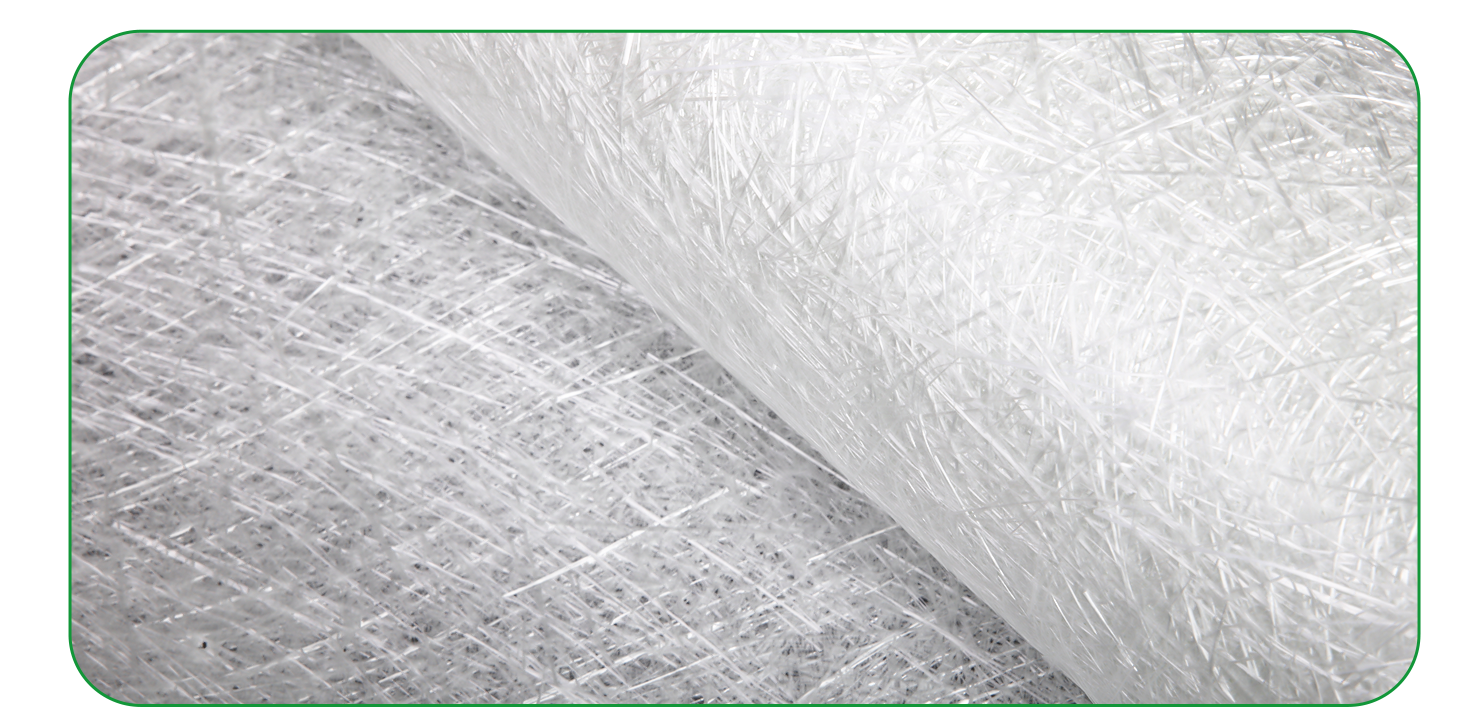

Industrial and Manufacturing Applications: The material’s heat resistance and dimensional stability make it an ideal choice for high-temperature applications. It is used as a reinforcing layer in roofing membranes, as a screen material in printing, and as a core component in the production of composite panels for the automotive and marine industries. Its lightweight nature contributes to fuel efficiency without compromising on strength.

Specialty and Niche Uses: In the agricultural sector, fiberglass mesh is used for insect screening and shading in greenhouses, allowing for precise climate control. It even finds its way into consumer products, providing reinforcement in laminate countertops and as a strengthening layer in various plastic products.

A Material Aligned with a Sustainable Future

One of the most compelling and positive aspects of fiberglass mesh is its contribution to sustainability. Its role in EIFS and other insulated cladding systems is directly linked to improved energy efficiency in buildings. By creating a continuous, reinforced thermal envelope, these systems significantly reduce heating and cooling demands, leading to lower carbon emissions and energy costs over the lifespan of a building.

Moreover, the durability it imparts directly combat the culture of disposability. Structures reinforced with fiberglass mesh require less frequent repairs and renovations, reducing the consumption of raw materials and the generation of construction waste. The material itself is inert, non-corrosive, and does not off-gas harmful chemicals, contributing to healthier indoor air quality and a reduced environmental footprint. As the global focus on green building intensifies, with standards like LEED and BREEAM becoming the norm, the attributes of fiberglass mesh position it as a material of choice for environmentally conscious projects.

Weaving a Stronger Tomorrow

Fiberglass mesh may not be the most glamorous material, but its positive impact is undeniable. It is a testament to human ingenuity—transforming simple glass into a flexible, incredibly strong fabric that underpins the safety, beauty, and longevity of our modern world. From the walls of our homes and offices to the advanced composites in transportation and infrastructure, this versatile grid works tirelessly out of sight. As we continue to build taller, smarter, and more sustainably, fiberglass mesh will undoubtedly remain an essential thread in the fabric of innovation, quietly reinforcing the foundations of our future.

Reinforcement,Durability,Fiberglass mesh,Crack Prevention,Tensile Strength,Composite Materials,Alkali-Resistant

Related news

Fiberglass Mesh: The Unseen Engine of Modern Durability and Design

2025-09-25

A New Era in Construction: Fiberglass Corner Mesh Transforms Building Durability and Efficiency

2025-09-22

Fiberglass Chopped Strand Mat: The Unsung Hero of Modern Composite Innovation

2025-09-09