Welcome To Hebei Xiongan Hengyun Technology Co., Ltd.

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Fiberglass Chopped Strand Mat: The Unsung Hero of Modern Composite Innovation

2025-09-09

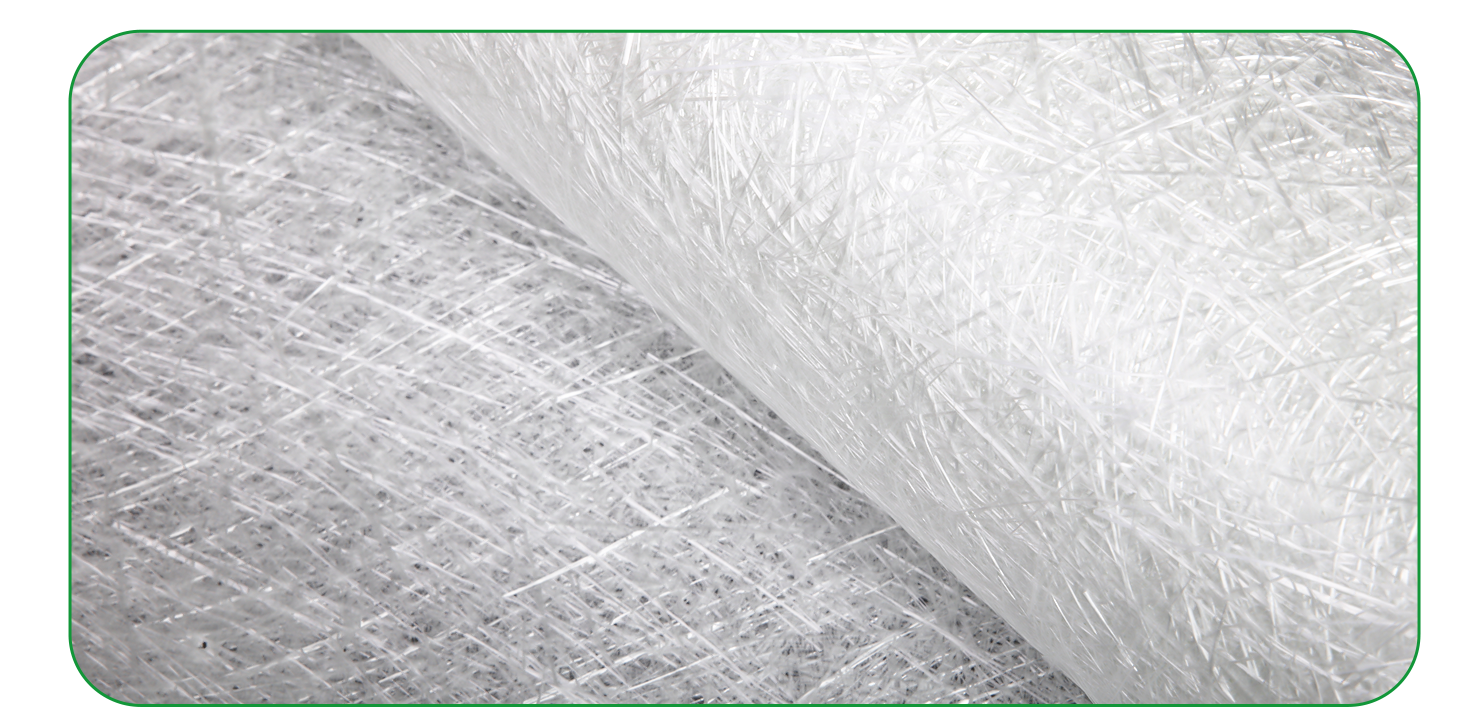

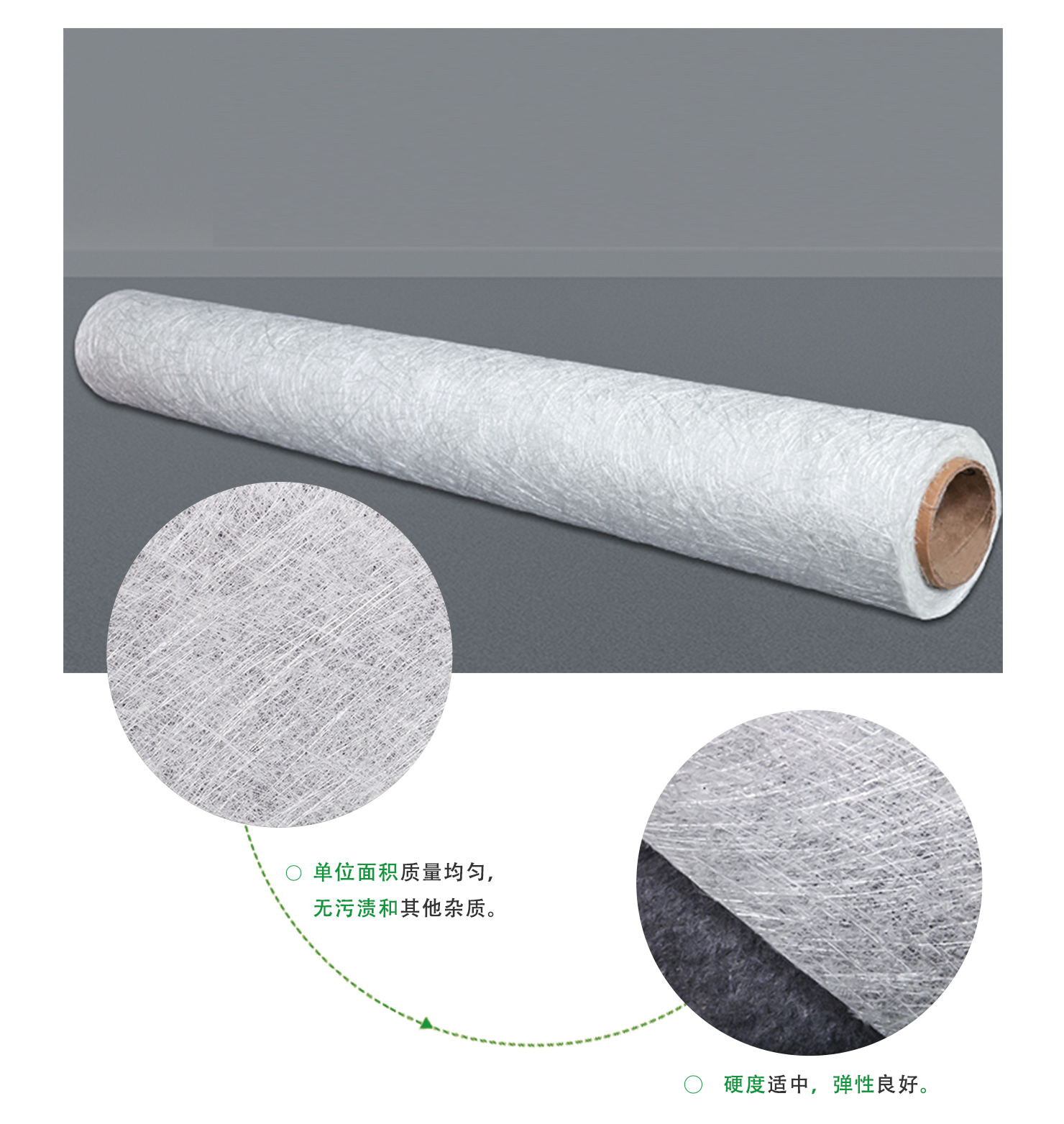

In the intricate tapestry of modern manufacturing, certain materials quietly underpin progress without capturing headlines. Among these unsung heroes is Fiberglass Chopped Strand Mat (CSM), a non-woven material composed of randomly distributed glass fibers held together by a chemical binder. While it may seem like a simple product, its impact is profound, serving as a foundational component in the composites industry and enabling advancements in transportation, energy, construction, and beyond. Its unique combination of versatility, strength, and cost-effectiveness continues to make it an indispensable asset for engineers and designers seeking to innovate responsibly and efficiently.

The Engine of Versatility and Ease of Use

The widespread adoption of Chopped Strand Mat is largely due to its remarkable versatility and user-friendly nature. Unlike woven fabrics, the random orientation of fibers in CSM provides uniform strength in all directions, making it exceptionally forgiving and easy to mold into complex shapes and contours. This isotropic property is crucial for manufacturing items with intricate designs, from sleek automotive body panels to the deep curves of a boat hull.

The primary application methods—hand lay-up and spray-up—are among the most accessible in composite manufacturing. In hand lay-up, sheets of CSM are simply placed into a mold, saturated with polyester or epoxy resin, and rolled out to remove air bubbles. This process requires minimal specialized equipment, opening the door for both large-scale industrial production and smaller custom fabricators, such as those building bespoke marine vessels or architectural features. The spray-up technique, where chopped strands and resin are simultaneously sprayed onto a mold, further automates the process, allowing for faster production rates for larger items like tubs, showers, and truck fairings. This ease of processing translates directly into reduced labor time and lower overall production costs, a key factor in its enduring popularity.

A Pillar of Strength and Durability

Beyond its ease of use, CSM delivers critical mechanical properties that enhance the durability and longevity of composite structures. When impregnated with resin, the mat forms a composite laminate that exhibits excellent tensile strength, impact resistance, and rigidity. While unidirectional or woven fabrics provide higher strength-to-weight ratios in specific directions, CSM provides balanced multi-directional strength and creates a robust backbone in a laminate stack. It is often used in combination with these other fabrics to build a hybrid structure that offers both tailored performance and overall resilience.

This durability makes it ideal for harsh environments. In the marine industry, CSM is a staple in the construction of boat hulls, decks, and internal structures because of its exceptional resistance to water, corrosion, and chemicals, far outperforming traditional materials like wood or metal. Similarly, in the water and wastewater treatment sector, storage tanks and piping systems manufactured with CSM withstand constant exposure to corrosive chemicals without degrading, ensuring long-term reliability and reducing maintenance costs.

Driving Sustainable Innovation

Perhaps one of the most significant and timely advantages of Fiberglass Chopped Strand Mat is its role in promoting sustainability across various sectors. This contribution manifests in several key ways:

-

Lightweighting for Efficiency: In the automotive and transportation industries, the push for reduced emissions is paramount. CSM-based composites are significantly lighter than steel or aluminum, contributing to the lightweighting of vehicles. A lighter car, truck, or aircraft requires less energy to propel, leading directly to improved fuel efficiency and reduced greenhouse gas emissions over the vehicle's lifespan.

-

Durability and Longevity: Products made with CSM are built to last. A corrosion-resistant water tank or a robust wind turbine blade nacelle built with CSM composites may have a service life measured in decades, far exceeding that of alternatives. This longevity reduces the need for frequent replacement, conserving resources and energy required for manufacturing new products.

-

Enabling Renewable Energy: The wind energy sector relies heavily on composite materials. CSM is frequently used in the interior layers of wind turbine blades, providing the necessary bulk and form to create the massive, aerodynamic structures that generate clean electricity. Without cost-effective materials like CSM, the scale of modern wind power innovation would be difficult to achieve.

The Future is Woven with Fiberglass

The future of Fiberglass Chopped Strand Mat is bright, evolving in tandem with material science. Ongoing research focuses on developing eco-friendly binders to enhance recyclability and reduce volatile organic compound (VOC) emissions during processing. Furthermore, its application is expanding into emerging fields such as infrastructure rehabilitation, where CSM fabrics are used to wrap and strengthen aging bridges and columns, and in the development of more efficient public transportation.

From the hull of a sailboat cutting through the ocean to the blade of a wind turbine harnessing the power of the air, Fiberglass Chopped Strand Mat is there, providing silent, reliable strength. It is a testament to how a seemingly simple material can become a cornerstone of modern industrial achievement, driving forward a future that is lighter, stronger, and more sustainable. Its story is not just one of fiber and resin, but one of endless possibility.

Related news

Fiberglass Chopped Strand Mat: The Unsung Hero of Modern Composite Innovation

2025-09-09

Weaving the Future: 7628 Electronic Fiberglass Fabric Powers the Next Generation of Electronics

2025-09-02

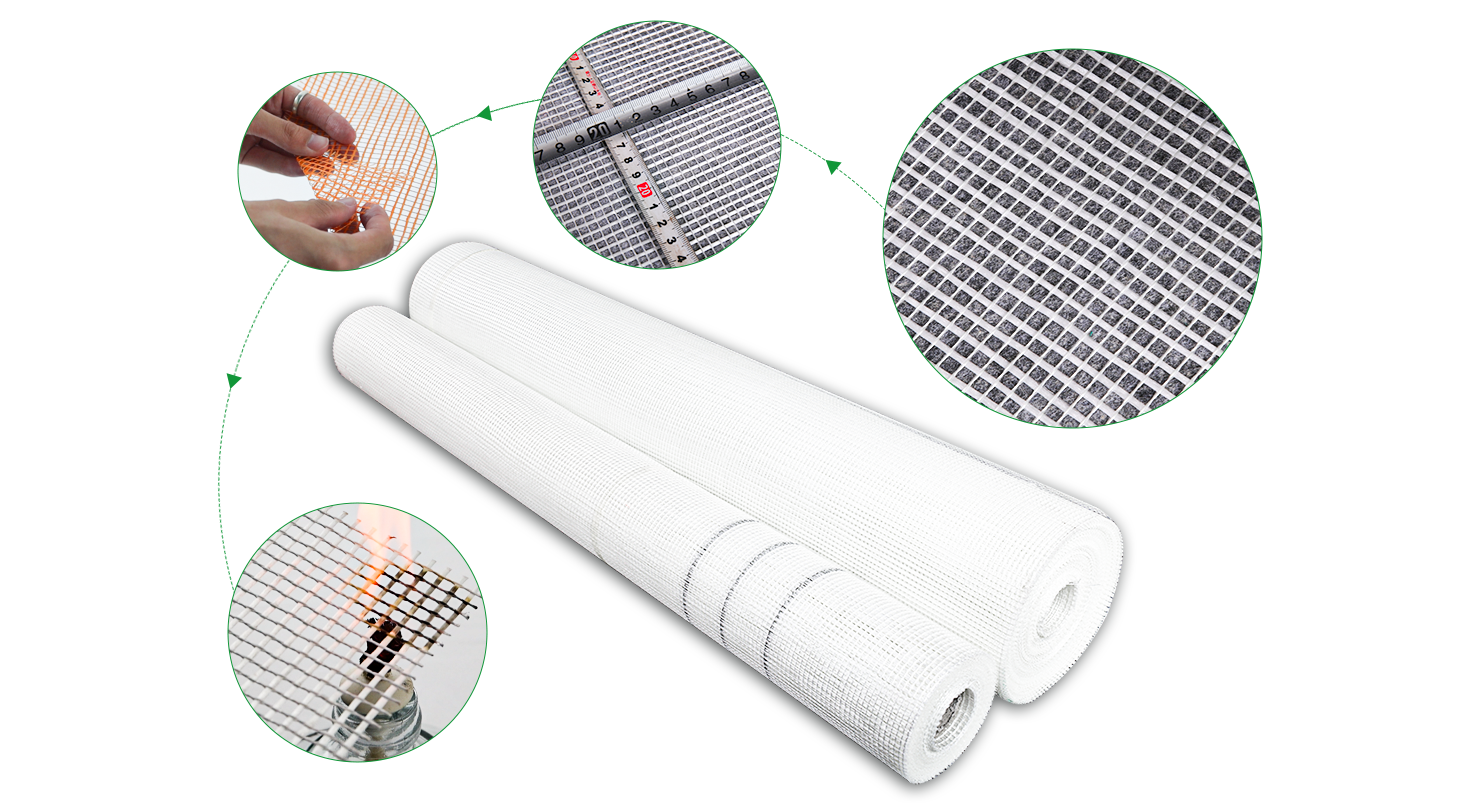

Fiberglass Mesh: The Unseen Backbone of Modern Construction and Innovation

2025-08-29