Welcome To Hebei Xiongan Hengyun Technology Co., Ltd.

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Weaving the Future: 7628 Electronic Fiberglass Fabric Powers the Next Generation of Electronics

2025-09-02

In the relentless pursuit of technological advancement, innovation often lies not just in the chips and circuits, but in the very foundation upon which they are built. Today, 7628 Electronic Fiberglass Fabric emerges from the labs and production floors as the unsung hero of the electronics revolution, providing the critical backbone for the printed circuit boards (PCBs) that power everything from everyday smartphones to sophisticated aerospace systems. This high-performance material is redefining industry standards, offering manufacturers an unparalleled combination of strength, stability, and signal integrity.

The Unseen Engine of Modern Technology

At the heart of nearly every modern electronic device is a PCB, and at the heart of most multilayer PCBs is a core material composed of electronic fiberglass fabric. The 7628 designation refers to a specific style of woven glass fabric characterized by its heavy, coarse weave and exceptional thickness. This style has become a cornerstone material for PCB substrates, particularly in applications demanding robust mechanical properties and superior electrical insulation.

"7628 fabric is more than just a component; it's a critical enabler," says Dr. Evelyn Reed, a materials scientist specializing in composite substrates. "It provides the structural integrity needed for complex, multi-layer board designs while maintaining the consistent dielectric properties essential for high-speed signal transmission. In an era where devices are getting smarter and more connected, the reliability of the underlying substrate is non-negotiable."

Unmatched Advantages for Demanding Applications

The widespread adoption of 7628 Electronic Fiberglass Fabric is driven by a powerful set of intrinsic benefits that directly address the core challenges faced by PCB designers and manufacturers.

Exceptional Dimensional Stability:

The heavy, balanced weave of 7628 fabric offers incredible resistance to warping and twisting during the intense heat and pressure of the PCB lamination process. This stability is paramount for ensuring layer-to-layer alignment in complex multilayer boards, preventing costly misregistration defects and production failures.

Superior Mechanical Strength:

The fabric's robust construction imparts outstanding rigidity and impact resistance to the finished PCB. This makes it the material of choice for applications that must withstand physical stress, vibration, and harsh operating environments. From automotive control units under the hood to industrial equipment on the factory floor, PCBs built on a 7628 foundation are renowned for their durability and long service life.

Consistent Dielectric Performance:

As electronic signals travel at ever-increasing speeds, the properties of the substrate material become a critical factor in signal integrity. 7628 fabric, when impregnated with high-quality epoxy resin (such as FR-4), provides uniform and predictable dielectric characteristics. This consistency minimizes signal loss, cross-talk, and electromagnetic interference (EMI), ensuring that devices perform reliably and efficiently.

Ideal for Thick Multilayer Boards:

The fabric's inherent thickness makes it perfect for constructing the internal cores of thick multilayer PCBs used in power supplies, server motherboards, and telecommunications infrastructure. It provides the necessary insulation and spacing between conductive layers, facilitating more complex and powerful circuit designs.

Driving Innovation Across Global Industries

The unique properties of 7628 Fiberglass Fabric have made it an indispensable material across a diverse spectrum of high-tech sectors.

In the telecommunications and data center industries, the push for faster 5G and eventual 6G networks requires PCBs that can handle high frequencies without degradation. The stability and electrical properties of 7628-based laminates are crucial for the base stations and network hardware that form the backbone of our connected world.

The automotive sector, particularly with the rise of electric vehicles (EVs) and advanced driver-assistance systems (ADAS), relies on extremely reliable electronics. PCBs made with 7628 fabric are found in battery management systems, powertrain controllers, and sensor arrays, where failure is not an option.

Furthermore, the aerospace and defense industries value this material for its ability to perform under extreme conditions of temperature, humidity, and vibration, ensuring the functionality of critical avionics and communication systems.

A Foundation for a Smarter, More Connected World

As the Internet of Things (IoT) continues to expand, embedding intelligence into countless objects, the demand for reliable, high-performance PCBs will only grow. 7628 Electronic Fiberglass Fabric stands ready to meet this challenge. Continuous improvements in glass fiber production and resin chemistry are further enhancing its performance, paving the way for even more advanced applications.

This remarkable material, though often unseen, is truly weaving the fabric of our technological future. By providing a foundation of unmatched strength, stability, and reliability, 7628 Electronic Fiberglass Fabric empowers engineers to innovate with confidence, ensuring that the next generation of electronic devices is not only more powerful but also more dependable than ever before.

7628 Electronic Fiberglass Fabric, dimensional stability, PCBs,dielectric performance,multilayer boards,telecommunications,automotive,signal integrity, aerospace,reliability

Related news

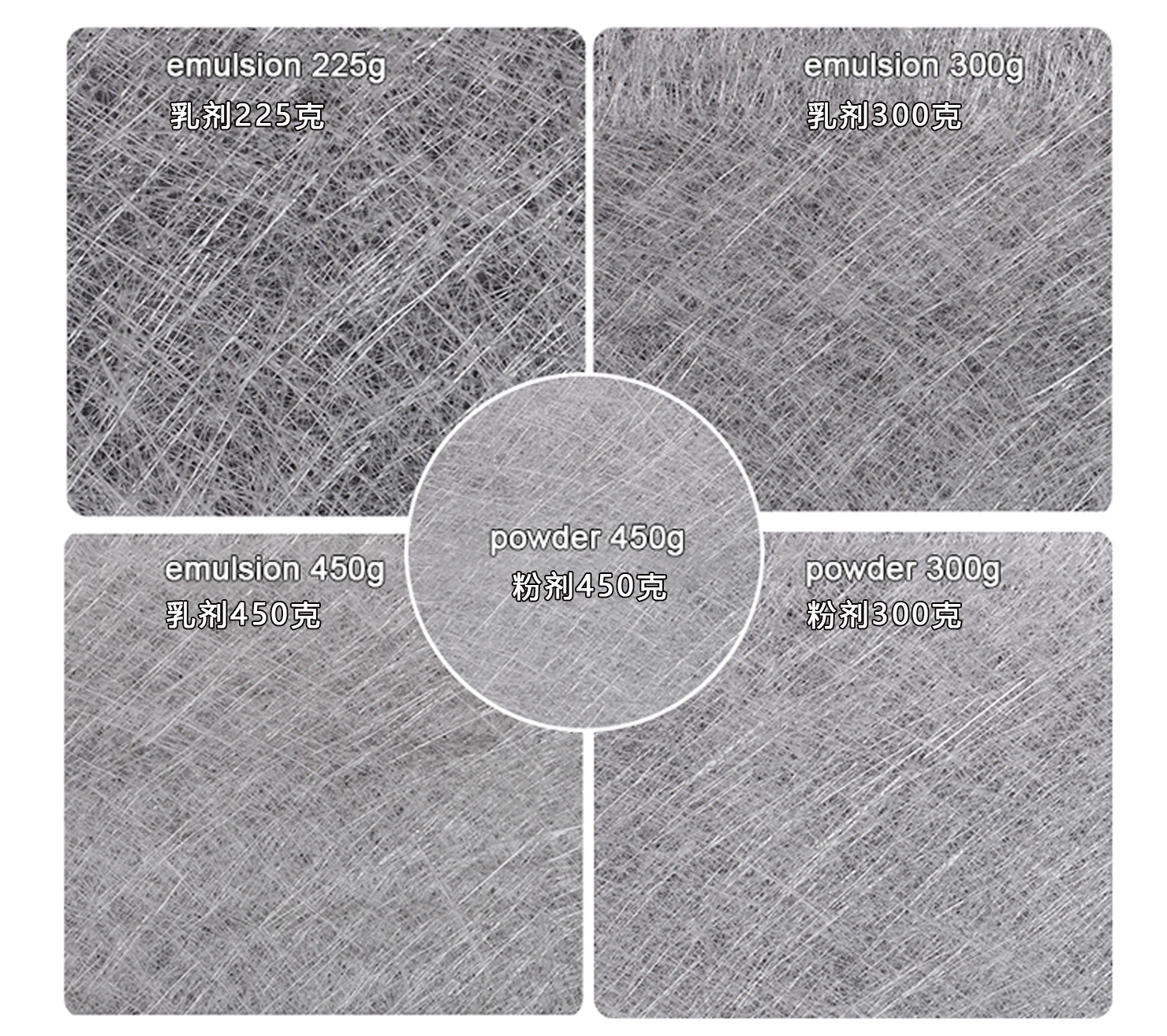

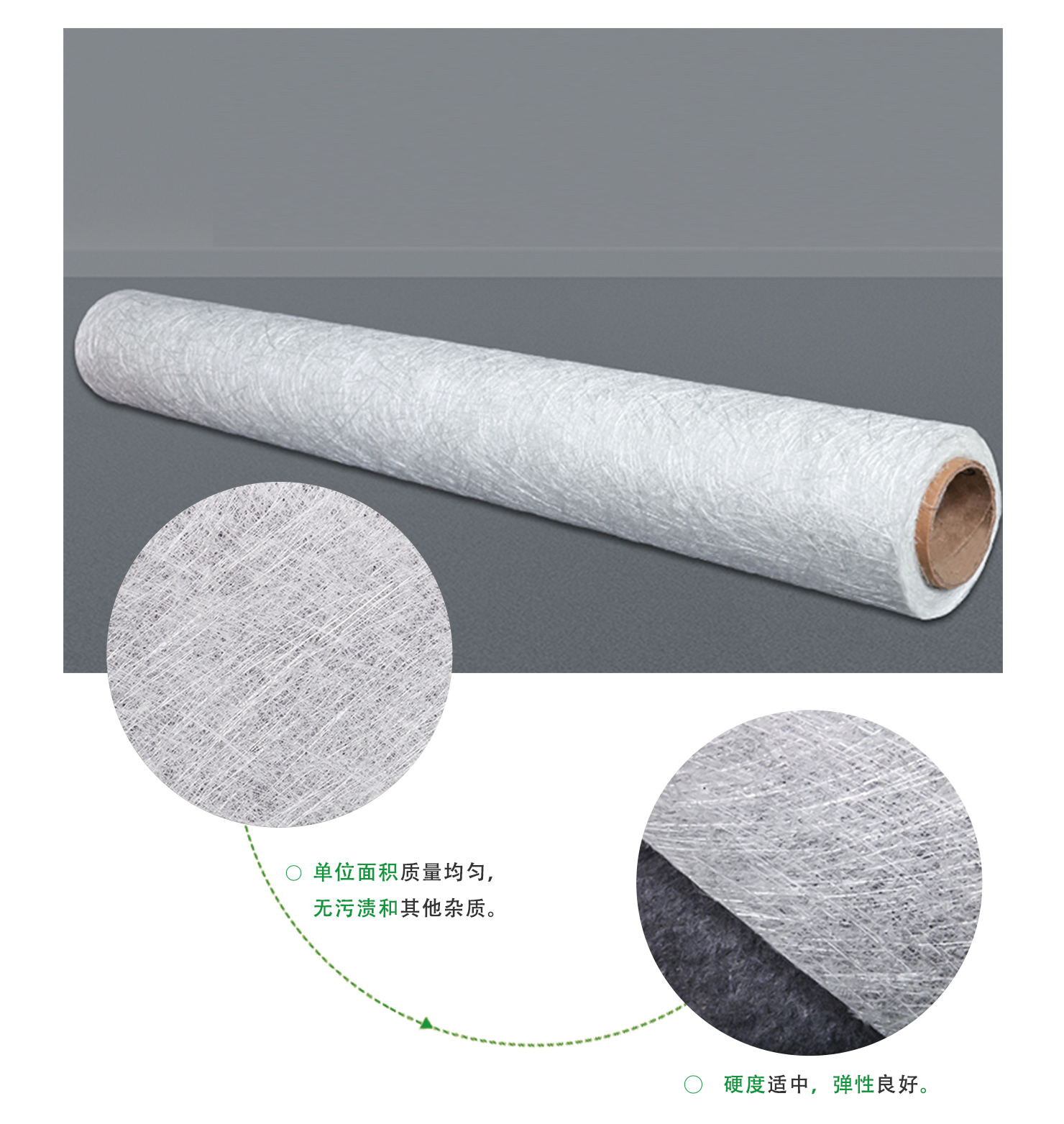

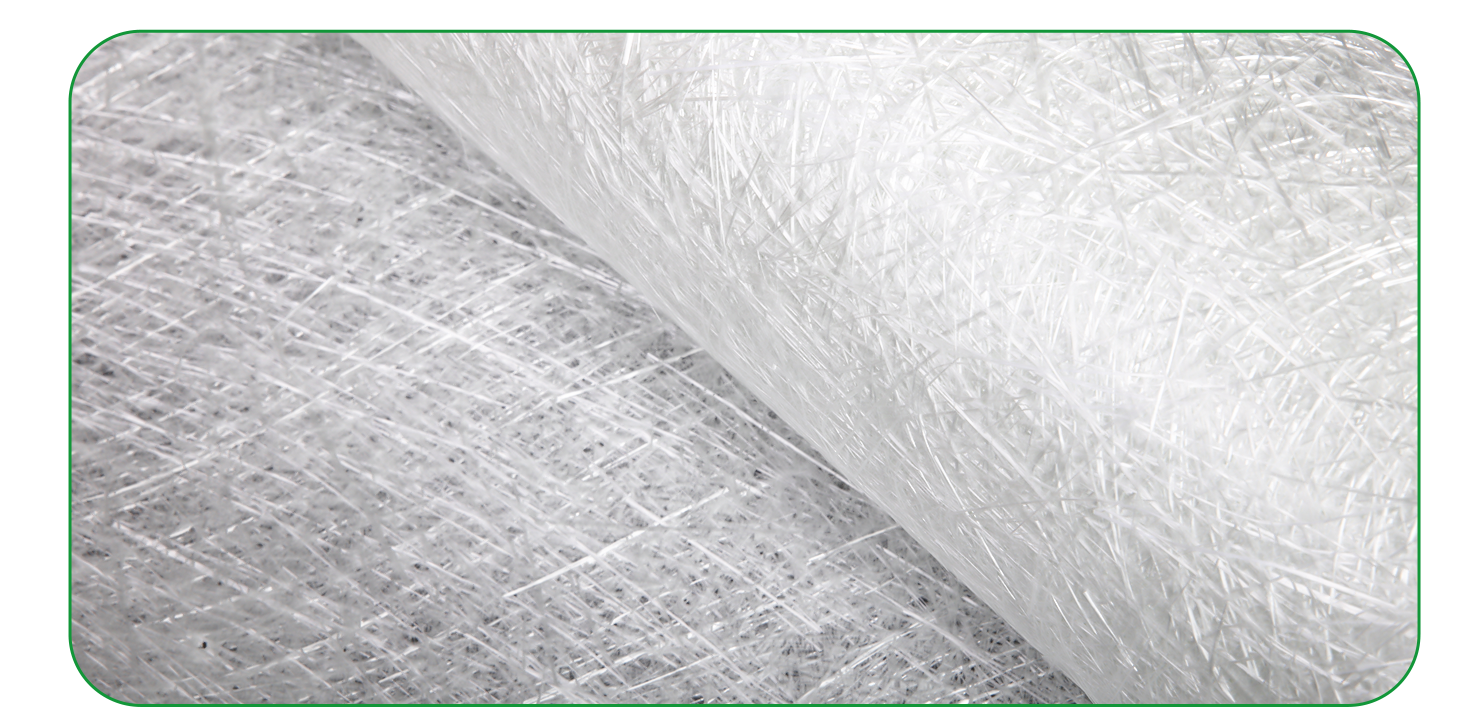

Fiberglass Chopped Strand Mat: The Unsung Hero of Modern Composite Innovation

2025-09-09

Weaving the Future: 7628 Electronic Fiberglass Fabric Powers the Next Generation of Electronics

2025-09-02

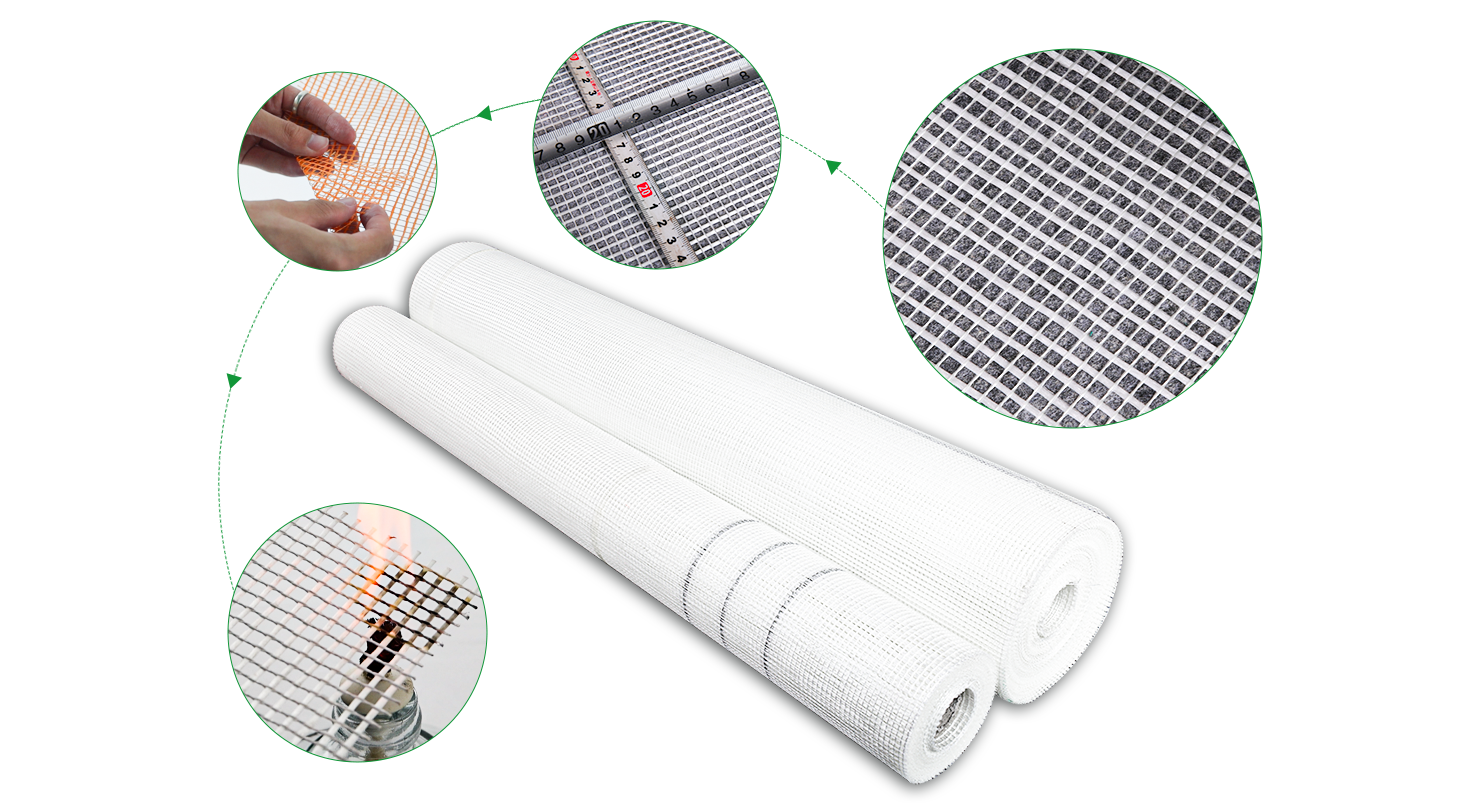

Fiberglass Mesh: The Unseen Backbone of Modern Construction and Innovation

2025-08-29