Welcome To Hebei Xiongan Hengyun Technology Co., Ltd.

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Fiberglass Corner Mesh: The Unsung Hero of Flawless, Durable Walls and Corners

2025-07-07

Fiberglass Corner Mesh: The Unsung Hero of Flawless, Durable Walls and Corners

In the intricate world of construction and renovation, achieving perfectly sharp, crack-free corners and durable wall surfaces is paramount. While drywall, plaster, and joint compound form the visible structure, a hidden reinforcement plays a critical role in ensuring longevity and aesthetics: Fiberglass Corner Mesh. This unassuming yet indispensable product is the cornerstone (literally and figuratively) of high-quality finishes in both interior and exterior applications. It's a specialized tape designed explicitly to reinforce and protect the vulnerable edges and joints where walls meet, ceilings intersect, and corners form.

I. The Introduction of Fiberglass Corner Mesh

At its core, fiberglass corner mesh is a composite material manufactured from fine, continuous glass filaments woven into a stable, open-grid mesh fabric. Unlike standard joint tape, it incorporates a pre-folded, rigid crease (typically a 90-degree angle) along its length. This crease is its defining feature. The mesh is then embedded with or coated by an alkaline-resistant compound, crucial for its performance in cementitious environments like plaster and stucco.

II. Key Components & Construction:

-

Glass Filaments: Provide exceptional tensile strength, flexibility, and dimensional stability. They don't stretch, rot, or corrode.

-

Open-Weave Mesh: Allows joint compound, plaster, or stucco to mechanically bond through the mesh, creating a monolithic reinforcement layer. This "keying" is essential for strength.

-

Pre-Folded Crease: Creates the perfect right angle for easy application onto inside or outside corners, ensuring straight, sharp lines.

-

Alkali-Resistant Coating: Protects the glass fibers from the high pH (alkaline) environment of cement-based plasters, stuccos, and setting-type joint compounds, preventing degradation over time.

-

Self-Adhesive Backing (Common but not universal): Many variants feature a pressure-sensitive adhesive on one side, allowing the mesh to stick temporarily to drywall or plasterboard surfaces before embedding. This simplifies application and positioning.

III. The Core Functions

-

Reinforcement & Crack Prevention: Corners and joints are inherent stress points. Building movement (settling, thermal expansion/contraction), impacts, and vibration can easily cause cracks to form along these lines. The mesh acts like rebar in concrete, distributing stresses over a wider area and significantly reducing the likelihood of cracks telegraphing through the finished surface. Its high tensile strength bridges minor gaps and holds the compound together.

-

Creating Sharp, True Corners: The rigid crease provides an instant guide for achieving perfectly straight 90-degree angles on both inside and outside corners. This is far more reliable than trying to form a sharp corner freehand with compound alone.

-

Impact Resistance: Reinforced corners are inherently more resistant to dings, bumps, and abrasion that commonly occur during furniture movement or everyday life.

-

Bonding & Integration: The open mesh allows the embedding material (joint compound, plaster, stucco) to penetrate fully, creating a strong mechanical bond that integrates the mesh seamlessly into the wall system. This prevents delamination.

-

Dimensional Stability: Unlike paper tape (which can bubble or wrinkle if wet out improperly), fiberglass mesh is dimensionally stable. It won't stretch, shrink, or distort when embedded in wet compound.

-

Moisture Resistance: Fiberglass itself is inorganic and unaffected by moisture. The alkali-resistant coating further protects it in damp environments (like bathrooms or exteriors), making it superior to paper tape in these situations.

IV. Applications

-

Drywall Finishing (Taping): Primarily used for reinforcing and finishing:

-

Inside Corners: Where two walls meet at an internal angle (most common).

-

Outside Corners: Where two walls meet at an external angle (e.g., wall edges, column corners, fireplace surrounds). Protects these vulnerable edges.

-

Ceiling/Wall Junctions: The joint where walls meet ceilings.

-

-

Plaster Systems: Used over plaster base (like blueboard) to reinforce corner beads and control joints within the plaster field.

-

Exterior Insulation and Finish Systems (EIFS): A critical component, reinforcing corners around windows, doors, and building edges within the synthetic stucco system.

-

Stucco Applications (Traditional & Synthetic): Reinforces corners and control joints in cement-based stucco finishes, preventing cracking.

-

Concrete Repair & Overlays: Used to reinforce corners in patching or resurfacing projects.

-

Tile Backer Board Corners: Reinforcing corners when using cement board or fiber-cement board for tile substrates.

V. Advantages Over Alternatives

-

Ease of Use: Self-adhesive versions stick instantly, eliminating the need for pre-embedding "bedding" coats required for paper tape. Faster application.

-

Crack Resistance: Generally superior long-term crack resistance due to higher tensile strength and better stress distribution.

-

Moisture Resistance: Performs better in humid environments or areas prone to minor moisture exposure.

-

No Bubbling/Wrinkling: Immune to the bubbling issues that can plague improperly applied paper tape.

-

Mold Resistance: The inorganic nature of fiberglass makes it less susceptible to mold growth compared to paper tape if exposed to moisture.

-

Durability: More resistant to damage during the finishing process and in-service life.

VI. Installation Process

-

Preparation: Ensure surfaces are clean, dry, and free of dust or debris. Corners should be sound.

-

Application: For self-adhesive mesh: Peel off the backing and carefully align the crease perfectly with the corner. Press firmly along the entire length, smoothing outwards onto each adjoining face. For non-adhesive mesh, apply a thin bed of compound into the corner first.

-

Embedding: Apply a layer of joint compound or plaster over the mesh wings on each side of the corner, using a taping knife. Firmly press the compound through the mesh, ensuring full encapsulation and eliminating air pockets. Feather the edges smoothly. The crease itself requires minimal compound directly on it initially.

-

Drying & Sanding: Allow the first coat to dry completely according to product instructions. Lightly sand if necessary to remove high spots or ridges.

-

Second/Third Coats: Apply subsequent, wider coats of compound, feathering further out each time to blend seamlessly with the wall surface. Each coat should be thinner than the last. Focus on building a smooth transition.

-

Final Sanding & Finishing: Once the final coat is dry, sand smooth to a ready-to-paint finish.

Crack Prevention,Wall Reinforcement,Fiberglass Corner Mesh,Drywall Corner Tape

Related news

Fiberglass Corner Mesh: The Unsung Hero of Flawless, Durable Walls and Corners

2025-07-07

Fiberglass Mesh Revolutionizes Modern Construction

2025-07-02

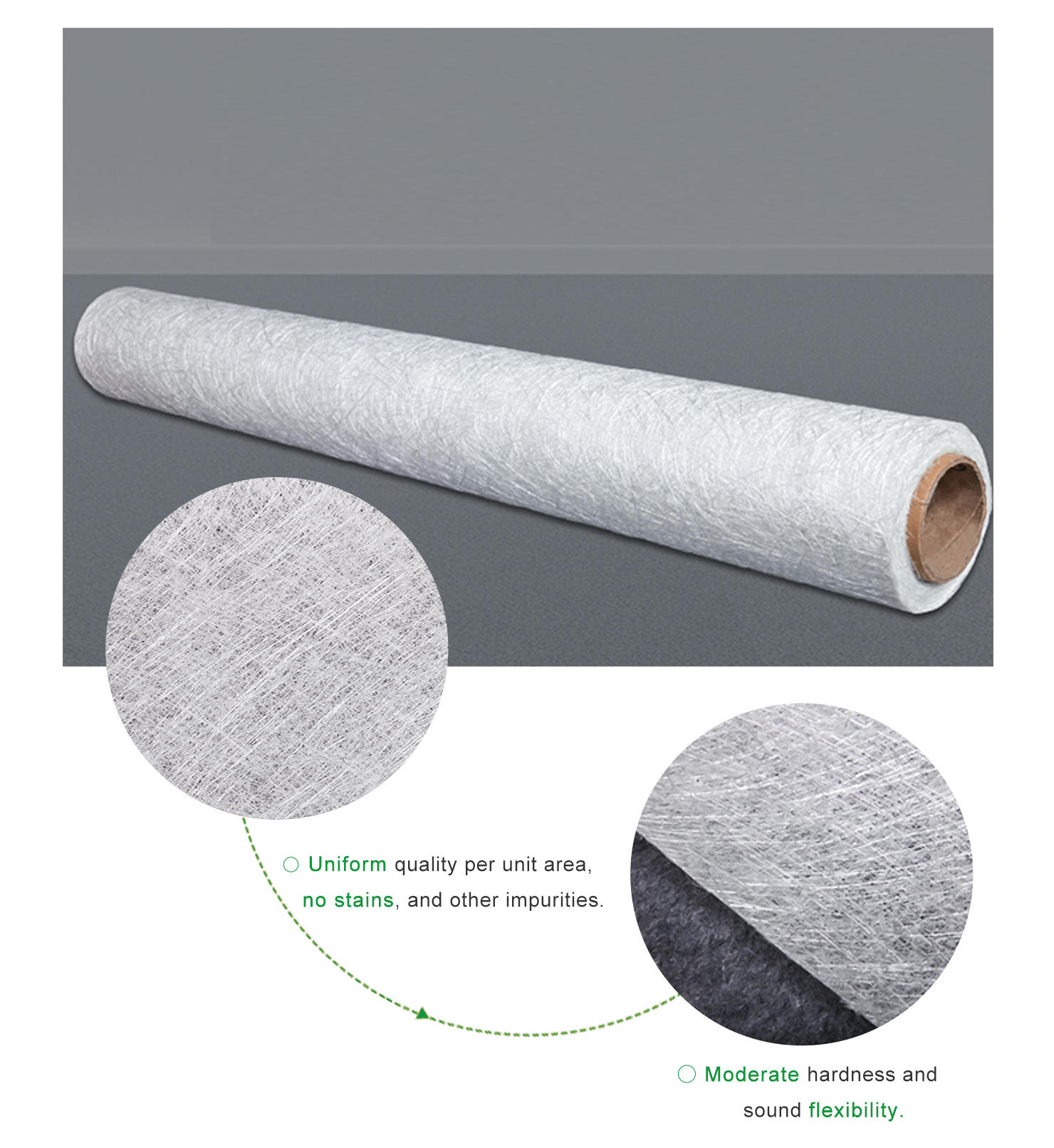

Fiberglass Chopped Strand Mat : The Versatile Workhorse of Composite Reinforcement

2025-07-02