Welcome To Hebei Xiongan Hengyun Technology Co., Ltd.

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Fiberglass Mesh Revolutionizes Modern Construction

2025-07-02

The construction industry is undergoing a significant transformation with the rising adoption of fiberglass mesh, a high-performance material that offers superior strength, flexibility, and durability. As builders and engineers seek alternatives to traditional steel reinforcements, fiberglass mesh has emerged as a leading solution for enhancing structural integrity while reducing costs and environmental impact.

Superior Performance in Reinforcement Applications

Fiberglass mesh is widely used in wall reinforcement, stucco systems, flooring, and road construction due to its exceptional tensile strength and resistance to cracking. Unlike metal reinforcements, it does not corrode, making it ideal for use in cement, plaster, and exterior insulation systems. Its alkali-resistant coating ensures long-term stability in high-pH environments, preventing degradation and extending the lifespan of construction projects.

Lightweight and Easy to Install

One of the key advantages of fiberglass mesh is its lightweight nature, which simplifies handling and installation. Unlike heavy steel mesh, it can be easily cut and shaped to fit complex surfaces, reducing labor time and costs. This flexibility makes it particularly useful in curved walls, ceilings, and decorative architectural elements.

Eco-Friendly and Sustainable

As sustainability becomes a priority in construction, fiberglass mesh stands out as an eco-friendly alternative to traditional materials. It is non-toxic, does not produce hazardous waste, and requires less energy to manufacture compared to steel. Additionally, its durability minimizes the need for frequent repairs, further reducing environmental impact.

Growing Market Demand and Innovation

The global fiberglass mesh market is projected to grow significantly, driven by increasing infrastructure development and the demand for high-performance, cost-effective materials. Manufacturers are investing in advanced weaving techniques and coatings to enhance its strength and adaptability for various climates and construction needs.

With its combination of durability, ease of use, and sustainability, fiberglass mesh is set to play a crucial role in the future of construction, offering a reliable solution for modern building challenges.

Fiberglass Mesh,Construction Reinforcement,Alkali-Resistant,Crack Prevention,Sustainable Building

Related news

Fiberglass Mesh Revolutionizes Modern Construction

2025-07-02

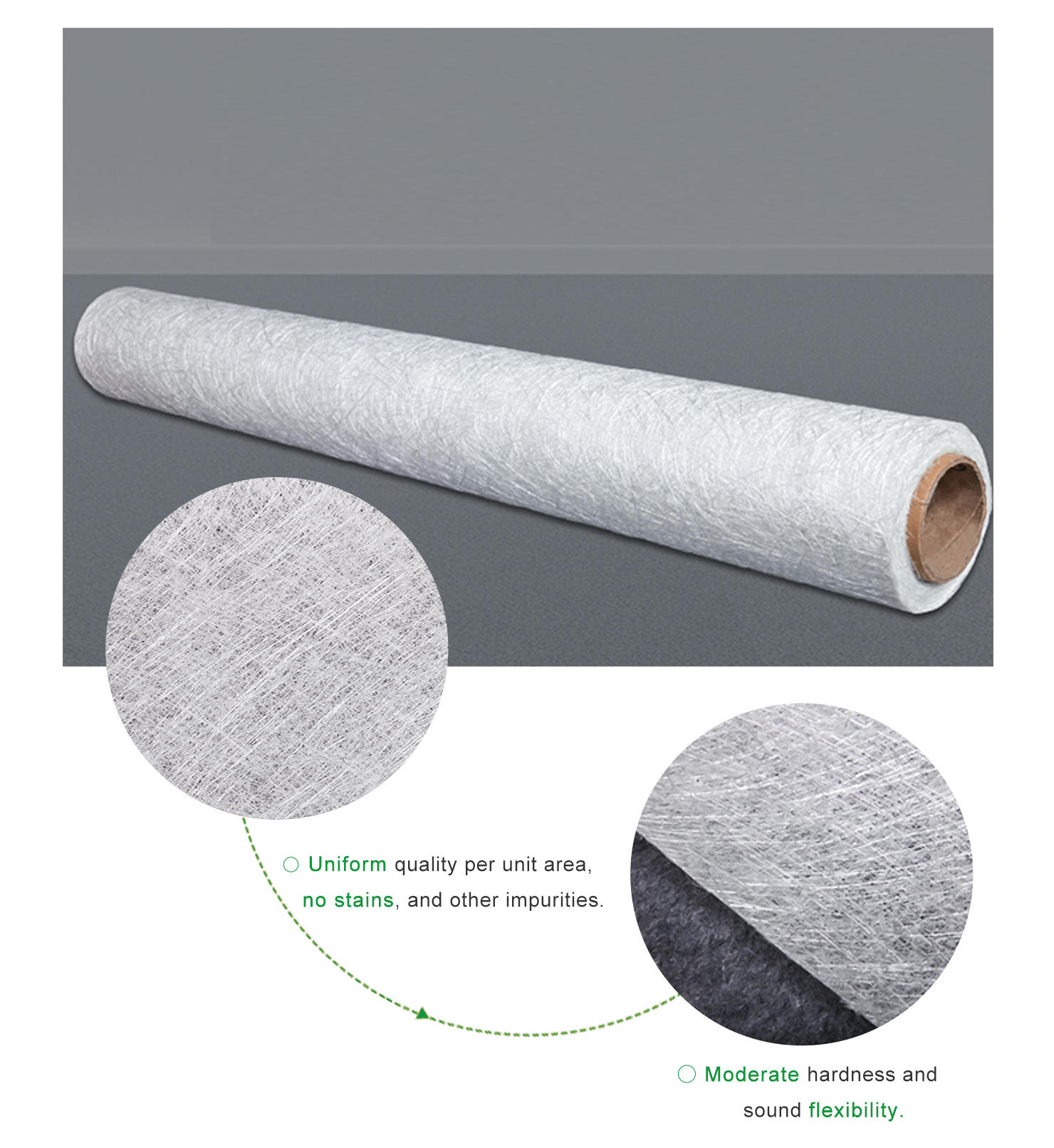

Fiberglass Chopped Strand Mat : The Versatile Workhorse of Composite Reinforcement

2025-07-02