Welcome To Hebei Xiongan Hengyun Technology Co., Ltd.

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Fiberglass Chopped Strand Mat: The Unsung Hero Powering Modern Manufacturing

2026-02-05

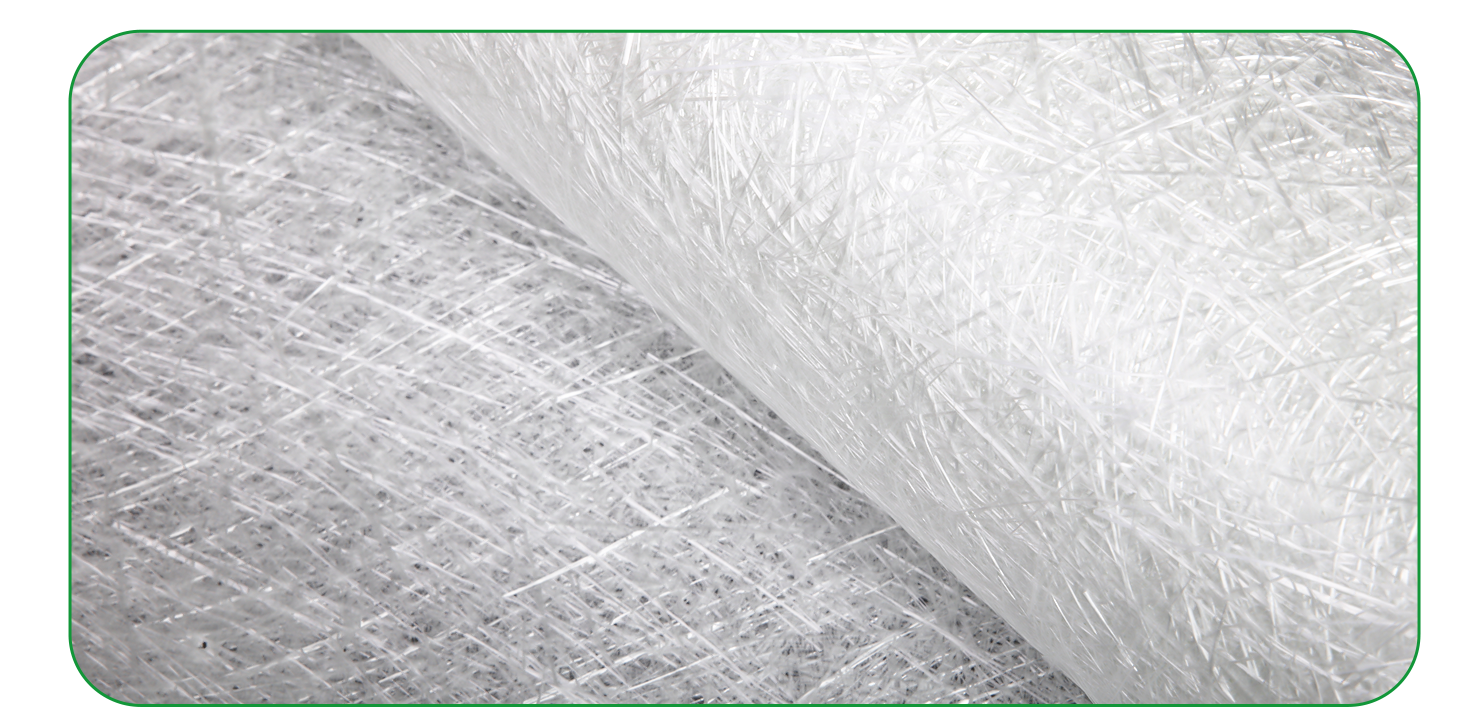

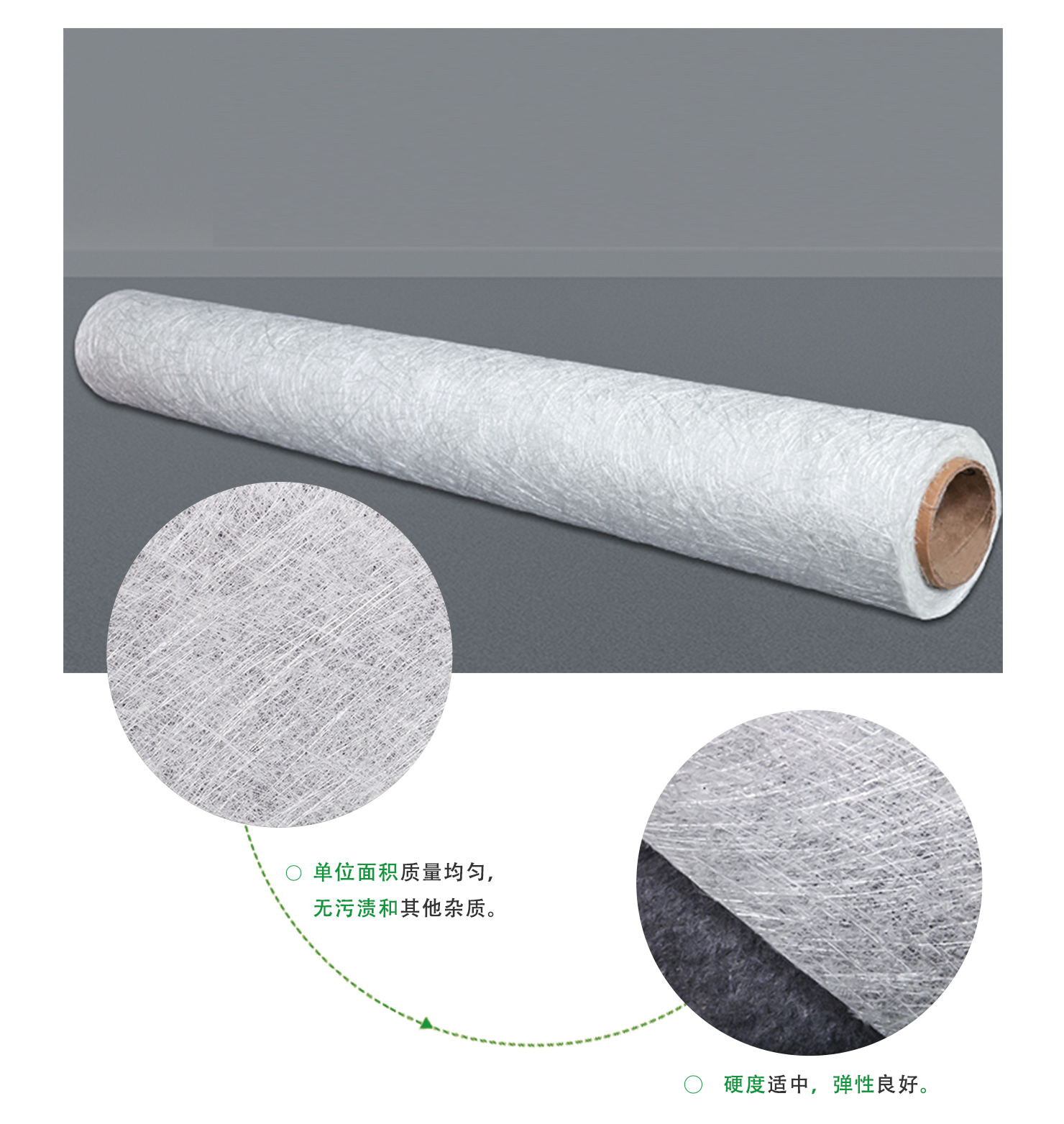

In the ever-evolving landscape of composite materials, one workhorse product continues to form the reliable foundation for countless applications: Fiberglass Chopped Strand Mat (CSM). As industries from marine to construction seek durable, lightweight, and economical solutions, CSM is experiencing a renaissance, reaffirming its critical role in global manufacturing. Composed of randomly distributed glass fibers bonded with a soluble binder, this non-woven mat is celebrated for its ease of use, excellent conformity to complex shapes, and superior resin compatibility.

The current surge in demand is largely attributed to CSM’s unparalleled versatility and cost-effectiveness. In an economic climate prioritizing efficiency without sacrificing quality, CSM delivers exceptional value. Its manufacturing process allows for high-volume production, keeping costs low and stable. For fabricators, this translates into a predictable material budget and reduced final product costs, a significant advantage in competitive markets like automotive parts, bathroom fixtures, and marine hulls. "In many applications, Chopped Strand Mat offers the optimal balance between performance and price," says Michael Thorne, an industry analyst at Composites Insights. "It provides isotropic strength—uniform properties in all directions—which is ideal for many molded parts, something woven fabrics can't achieve at the same price point."

Beyond economics, CSM is driving innovation by making composite fabrication more accessible. Its user-friendly nature is ideal for both large-scale industrial operations and smaller workshops employing hand lay-up or resin transfer molding techniques. Workers can easily cut and layer the mat to build up thickness precisely where needed, enabling the creation of strong, resilient structures with minimal waste. This adaptability is crucial for the renewable energy sector, where CSM is extensively used in fabricating wind turbine blade interiors and water turbine components, contributing directly to the green energy transition.

Furthermore, the material's compatibility with various resins, including polyester, vinyl ester, and epoxy, allows engineers to tailor the composite's final properties for specific environmental challenges, such as water resistance in boats or chemical corrosion in storage tanks. Recent developments in binder technology have also improved the wet-out characteristics of CSM, leading to faster production cycles, reduced voids, and even stronger finished products.

The construction industry is another major beneficiary. CSM is integral to fabricating panels, ducts, and roofing elements that are lightweight yet strong, and impervious to rust and rot. Its use in sanitary products ensures hygienic, easy-to-clean surfaces that last for decades. As infrastructure projects worldwide emphasize longevity and sustainability, the corrosion-resistant nature of CSM-based composites presents a compelling alternative to traditional materials like steel and wood.

Looking ahead, the future of Chopped Strand Mat appears intertwined with the broader growth of the composites industry. While advanced fabrics like unidirectional and multiaxial weaves gain ground in high-performance niches, CSM remains indispensable for the vast majority of general composite applications. Its evolution continues, with research focused on enhancing its sustainability profile through bio-based binders and increased use of recycled glass content.

In conclusion, Fiberglass Chopped Strand Mat is far from a legacy material. It is a dynamic, evolving solution that effectively meets the core needs of modern fabrication. By offering a reliable, economical, and versatile pathway to creating durable products, CSM solidly reinforces its position as the fundamental backbone of the global composites industry, proving that true value often lies in consistent, adaptable, and trusted performance.

Chopped Strand Mat,Fiberglass,Versatile,Cost-Effective,Composite Reinforcement,Ease of Use,Industrial Applications

Related news

Fiberglass Chopped Strand Mat: The Unsung Hero Powering Modern Manufacturing

2026-02-05

2026-02-02

Fiberglass Corner Mesh: The Unsung Hero in Modern Construction Excellence

2026-01-29