Welcome To Hebei Xiongan Hengyun Technology Co., Ltd.

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

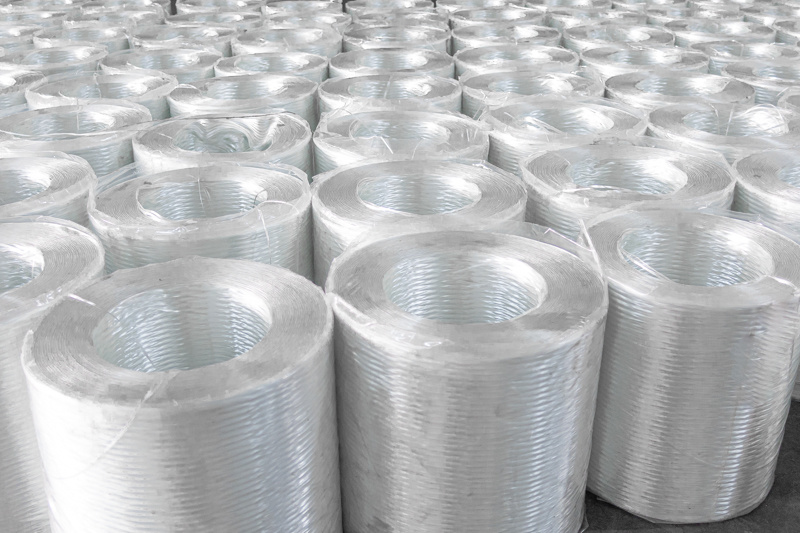

High - Strength, Lightweight, and Versatile: The Marvel of Fiberglass Roving

2025-04-22

What is Fiberglass Roving?

Fiberglass roving is composed of long, thin glass fibers. These fibers are typically drawn from a large spool and passed through a sizing bath, where they are coated with sizing chemicals. This coating not only protects the fibers but also improves their adhesion to resins in composite applications. The fibers are then wound onto a take - up reel and may be cut to the desired length. A strand of glass fiber roving can consist of anywhere from a few dozen to over 500 filaments. For instance, a strand with 50 - 100 filaments is considered a medium roving, while one with more than 500 filaments is a large roving.

Production Process

The production of fiberglass roving begins with the melting of raw materials, usually glass balls or waste glass. High - temperature melting is required to transform the solid glass into a molten state that can be drawn into fine fibers. After melting, the glass is extruded through tiny orifices in a bushing to form individual filaments. These filaments are then grouped together and wound onto a bobbin to form the roving. The entire process is carefully controlled to ensure consistent fiber diameter and quality.

Properties that Make it Stand Out

- High Strength - to - Weight Ratio: Glass fiber roving offers an impressive strength - to - weight ratio. It is much lighter than many traditional materials like steel, yet it can withstand significant pulling forces without breaking. This property makes it an ideal choice for applications where weight reduction is crucial, such as in the aerospace and automotive industries.

- Excellent Heat Resistance: Glass fiber roving maintains its physical and chemical properties at high temperatures. It does not soften or melt easily, allowing products made with it to perform well in high - temperature environments. This heat resistance is particularly valuable in industries like manufacturing and power generation.

- Electrical Insulation: It has outstanding electrical insulation properties, making it suitable for use in electrical and electronic applications. For example, it can be used in the production of circuit boards and electrical insulation materials.

- Chemical Stability: Fiberglass roving is highly resistant to chemical corrosion. It does not react with most acids, alkalis, and solvents, ensuring the durability of products in harsh chemical environments. This property is beneficial in industries such as chemical processing and wastewater treatment.

- Low Hairiness: The amount of hairiness in fiberglass roving is relatively low, resulting in a smooth finished surface. This is important for applications where aesthetics and surface quality are critical, such as in the production of high - end consumer goods.

Applications Across Industries

- Aerospace: In the aerospace industry, fiberglass roving is used to reinforce composite materials for aircraft components. Its high strength - to - weight ratio helps to reduce the weight of the aircraft, which in turn improves fuel efficiency and performance. Components such as aircraft wings, fuselages, and interior panels may incorporate glass fiber - reinforced composites.

- Automotive Manufacturing: Fiberglass roving is widely used in the automotive industry. It is used to make parts such as car bodies, bumpers, and interior components. By using glass fiber - reinforced composites, car manufacturers can reduce the weight of vehicles, leading to better fuel economy and lower emissions. Additionally, the high strength of these composites provides enhanced safety features.

- Construction: In construction, glass fiber roving is used in a variety of applications. It can be used to reinforce concrete, making it stronger and more durable. It is also used in the production of building panels, insulation materials, and roofing materials. For example, fiberglass - reinforced plastic (GRP) panels are often used for exterior cladding due to their weather resistance and aesthetic appeal.

- Marine Industry: Boats and ships often use fiberglass roving in their construction. The material's resistance to water and chemicals makes it suitable for use in marine environments. Fiberglass - reinforced hulls are lightweight, yet strong enough to withstand the harsh conditions of the sea.

- Sports Equipment: Glass fiber roving is used to make sports equipment such as golf clubs, tennis rackets, and bicycle frames. The high strength and flexibility of the material allow for the creation of lightweight and high - performance sports gear.

high strength - to - weight ratio, heat resistance,electrical insulation,chemical stability, low hairiness,aerospace,automotive,construction,sports equipment

Related news

2025-04-24

High - Strength, Lightweight, and Versatile: The Marvel of Fiberglass Roving

2025-04-22

Aluminum Foil Fiberglass Cloth for Fire Protection and Heat Insulation

2025-04-21